Double face leather cloth and production process thereof

A production process and fur technology, applied in liquid/gas/steam textile material processing, knitting, dyeing, etc., can solve the problems of shortening the production cycle of fabric manufacturing, hard composite fabrics, and reducing production costs, so as to shorten the production cycle , soft hand feeling, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

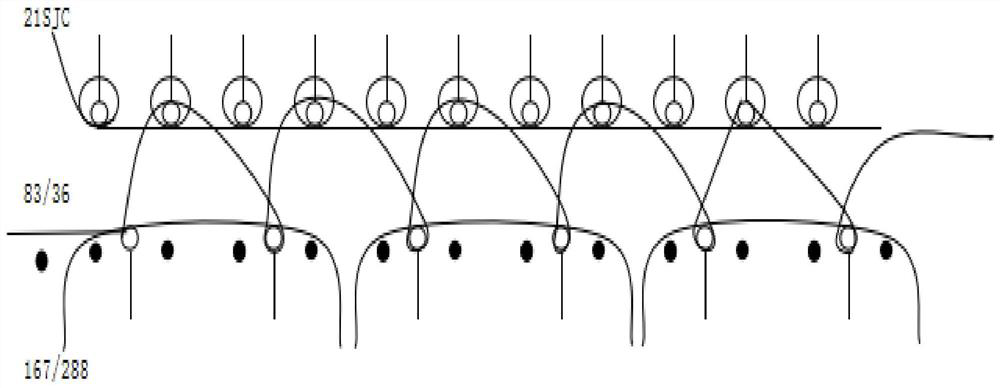

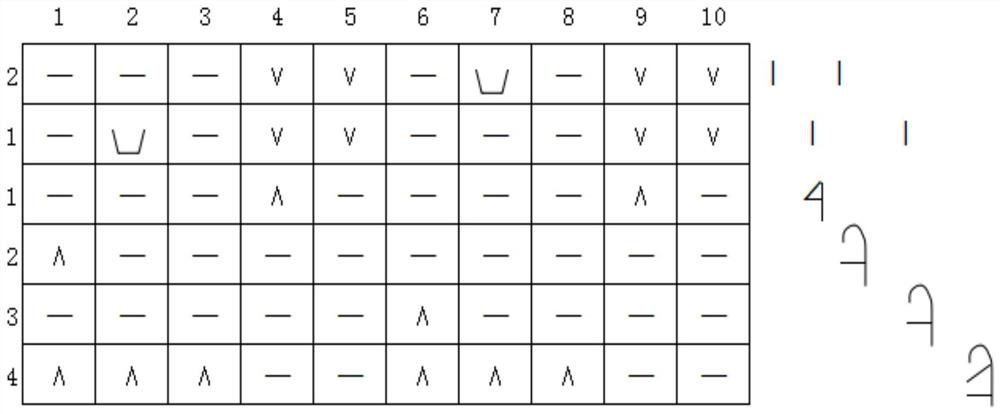

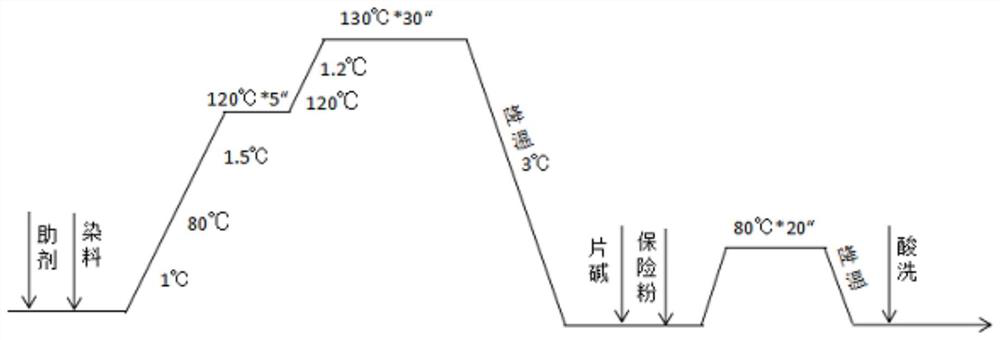

[0026]The present invention adopts the weft double-face machine structure, the front side of the fabric is used for 167dtex / 288f polyester filaments, the reverse surface 21Sjc, the intermediate connection of the yarn 83dtex / 36f, and the tension of the yarn is strictly controlled when weaving, the size is suitable and uniform, and the pulling tension is suitable. Direct cross-sectional cables in knitting machines. By specific weaving process parameters, after booking, dyeing, softening, dehydration, drying, combing, hot light, hair, comb, shaking, and grain, fabric, gray cloth weaving machine type hair 20-35mm Between 180-550g of 180-550g, the blank can be adjusted accordingly accordingly according to the gray cloth, the tissue structure can be diversified; the syringe diameter is 914mm (36 inches), the needle length 16 / 22 needle / inch, into the line Number 16.

[0027]Referfigure 1 ,2The present invention refers to the two-stage pin, woven 10 channels, and the woven time 10 channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com