Method and device for producing carbon source by using kitchen garbage

A kitchen waste and carbon source technology, applied in microorganism-based methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of difficult to control fermentation conditions, and achieve easy control of the fermentation process, low volatility, Ingredient stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

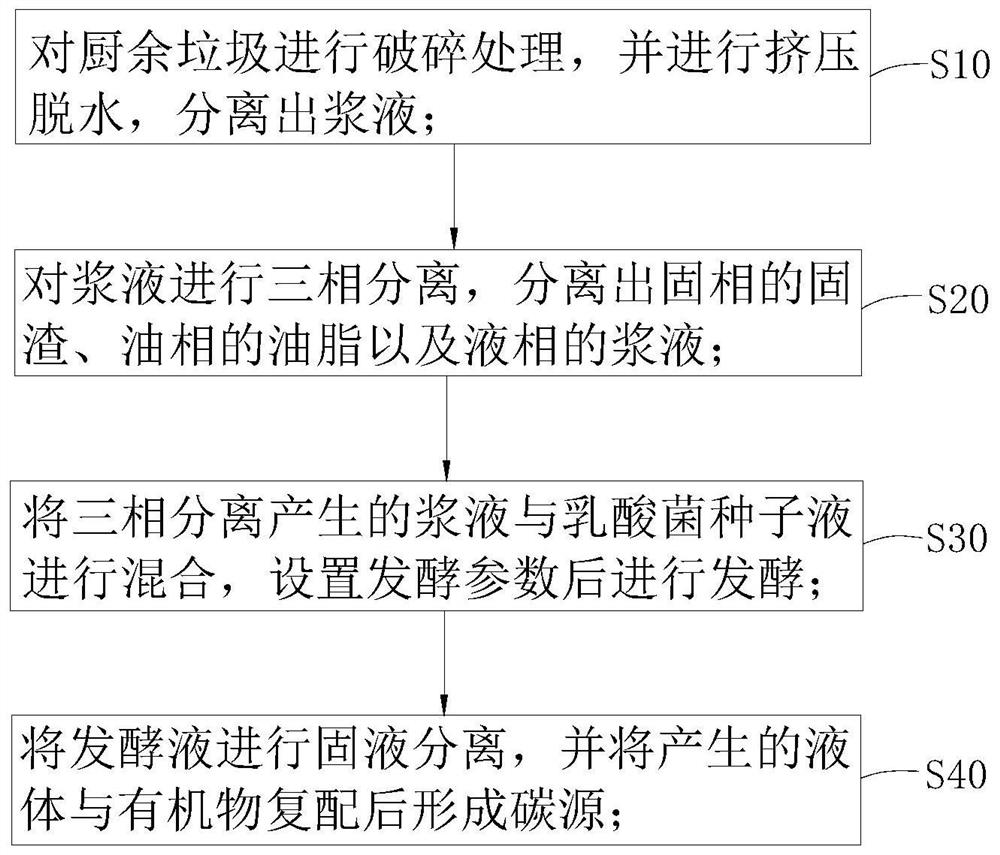

Method used

Image

Examples

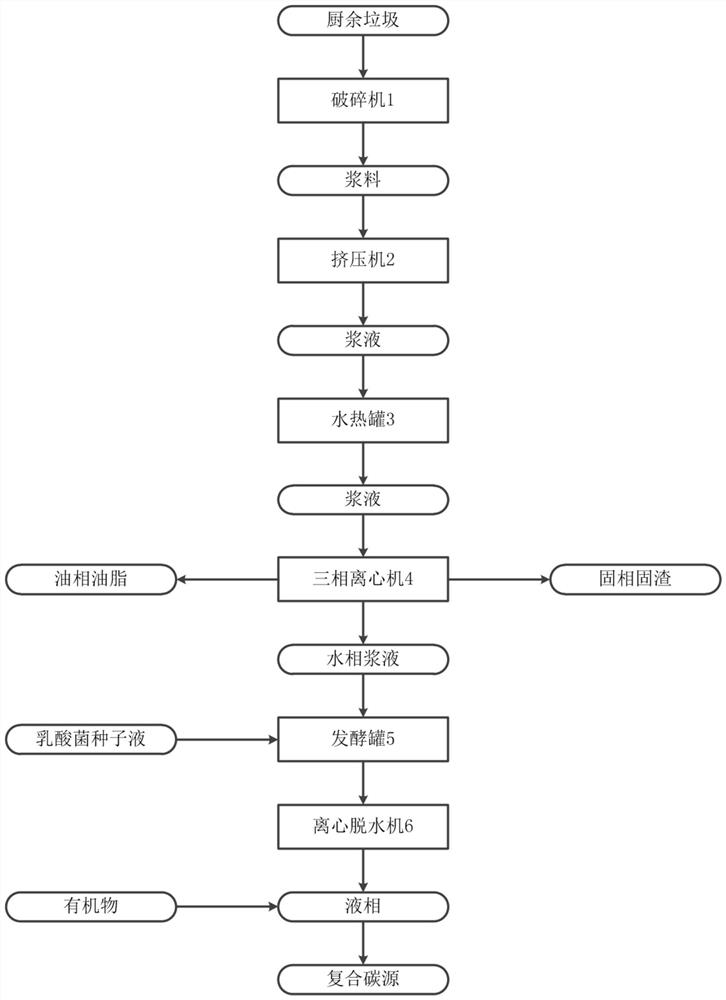

Embodiment 1

[0050] Municipal food waste is collected and transported, sorted to remove non-fermentable metals, plastics and other sundries, water is added to adjust the solid-liquid ratio to 1:3, crushing and refining and three-stage extrusion dehydration are carried out to make kitchen waste slurry. The slurry is pumped into the water heating tank 3, heated to 100° C. by steam, heated in water for 45 minutes, and the crude oil is extracted through the three-phase centrifuge 4. The slurry after the oil extraction is pumped into the fermenter 5, and 5% of the seed liquid is inserted to adjust the pH value to 6.0, and the organic load is 150kgVSm -3 d -1 , fermentation temperature 40 ℃, fermentation 72h. After fermentation, the liquid is separated from solid and liquid using a centrifugal dehydrator 6, and the separated liquid phase is compounded with 25% sodium acetate at a mass ratio of 3:1, which is a composite carbon source.

Embodiment 2

[0052] Municipal food waste is collected and transported, sorted to remove non-fermentable metals, plastics and other sundries, water is added to adjust the solid-liquid ratio to 1:2, crushing and refining and three-stage extrusion dehydration are carried out to make kitchen waste slurry. The slurry is pumped into the water heat tank 3, heated to 90° C. by steam, heated in water for 30 minutes, and the crude oil is extracted through the three-phase centrifuge 4. The slurry after the oil extraction is pumped into the fermenter 5, and 5% of the seed solution is inserted to adjust the pH value to 7.0, and the organic load is 10kgVSm -3 d -1 , fermentation temperature 35°C, fermentation 48h. After fermentation, the liquid is separated from solid and liquid using centrifugal dehydrator 6, and the separated liquid phase is compounded with 25% sodium acetate at a ratio of 3:1, which is a composite carbon source.

Embodiment 3

[0054] Municipal food waste is collected and transported, sorted to remove non-fermentable metals, plastics and other sundries, water is added to adjust the solid-liquid ratio to 1:4, crushing and refining and three-stage extrusion dehydration are carried out to make kitchen waste slurry. The slurry is pumped into the water heat tank 3, heated to 100° C. by steam, heated in water for 60 minutes, and the crude oil is extracted through the three-phase centrifuge 4. The slurry after the oil extraction is pumped into the fermenter 5, inserts 5% seed liquid, adjusts the pH value to 5.0, and the organic load is 20kgVSm -3 d -1 , fermentation temperature 50 ℃, fermentation 96h. After fermentation, the liquid is separated from solid and liquid using centrifugal dehydrator 6, and the separated liquid phase is compounded with 25% sodium acetate at a ratio of 3:1, which is a composite carbon source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com