Method for catalytic synthesis of biodiesel by using solid acid catalyst

A solid acid catalyst, biodiesel technology, applied in the direction of biofuel, fatty acid esterification, fat production, etc., can solve the problems of increased biodiesel cost, emulsification, high energy consumption, etc., and achieve good economic and environmental benefits, material consumption and The effect of reduced energy consumption and low product coloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

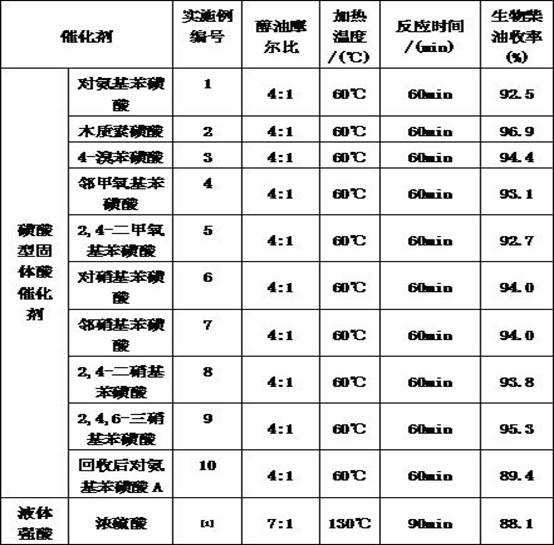

Embodiment 1

[0016] Weigh 50.0g of catering waste oil, centrifuge it to remove impurities mechanically, remove the moisture of catering waste oil, and obtain the pretreated catering waste oil. After pretreatment, the mass ratio of catering waste oil, methanol and p-aminobenzenesulfonic acid is 100:45:0.10. At 60°C, stir and react for 60 minutes, then let it stand for 1 hour, separate layers, take the upper liquid, and recover methanol through evaporation to obtain Biodiesel: The lower layer liquid is evaporated to recover methanol and glycerin at the same time, and the yield of biodiesel reaches 92.5%.

Embodiment 2

[0018] Weigh 50.0g of catering waste oil, centrifuge it to remove impurities mechanically, remove the moisture of catering waste oil, and obtain the pretreated catering waste oil. After pretreatment, the mass ratio of catering waste oil, methanol and ligninsulfonic acid is 100:45:0.40. At 60°C, stir and react for 60 minutes, then let it stand for 1 hour, separate layers, take the upper liquid, recover methanol through evaporation, and obtain biological Diesel oil; take the lower layer of liquid and evaporate to remove methanol and recover, and recover glycerin at the same time, the yield of biodiesel reaches 96.9%.

Embodiment 3

[0020] Weigh 50.0g of catering waste oil, centrifuge it to remove impurities mechanically, remove the moisture of catering waste oil, and obtain the pretreated catering waste oil. After pretreatment, the mass ratio of catering waste oil, methanol and 4-bromobenzenesulfonic acid is 100:45:0.27. At 60°C, stir and react for 60 minutes, then let it stand for 1 hour, separate layers, take the upper liquid, and recover methanol by evaporation. Biodiesel is obtained; the lower layer liquid is evaporated to recover methanol and glycerol at the same time, and the yield of biodiesel reaches 94.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com