Preparation method of waterborne polyurethane/inorganic nanocomposite coating with biomimetic micropatterning

A water-based polyurethane, inorganic nano technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve rare problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0025] Weigh the nano hexagonal boron nitride 10 g, add 30 ml of acetone, ultrasonic dispersion for 30 min to obtain the dispersion; add 100 g of waterborne polyurethane emulsion with a solid content of 30%, add 20 ml of absolute ethanol under high-speed stirring, continue to stir for 30 min, to obtain aqueous polyurethane / nano boron nitride emulsion; take an appropriate amount of the above emulsion into the PP box, dry at 60 °C for 24 hours, to obtain a biomimetic micro-patterned aqueous polyurethane / nano boron nitride coating.

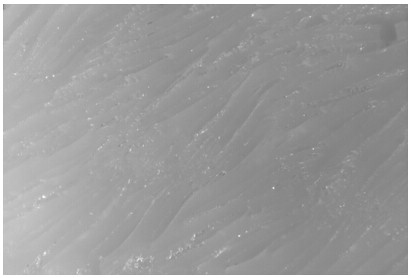

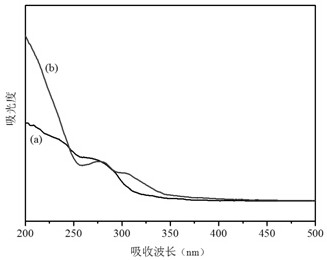

[0026] Preparation of micro-patterned waterborne polyurethane / nano boron nitride coating surface polarization microscopy photographs such as Figure 1 as shown. from Figure 1 It can be seen that a regular feather-like bionic pattern was prepared. Figure 2 Respectively , (a) are pure waterborne polyurethanes; (b) Solid ultraviolet spectra of micro-patterned waterborne polyurethane / nanoboron nitride composites, from which it can be seen that the ultrav...

Embodiment approach 2

[0028] Weigh the nano hexagon boron nitride 15 g, add 30 ml of acetone, ultrasonic dispersion for 30 min to obtain the dispersion; add 100 g of waterborne polyurethane emulsion with a solid content of 30%, add 50 ml of absolute ethanol under high-speed stirring, continue to stir for 30 min, to obtain aqueous polyurethane / nano boron nitride emulsion; take an appropriate amount of the above emulsion into the PP box, dry at 60 °C for 24 hours, to obtain a biomimetic micro-patterned waterborne polyurethane / nano boron nitride coating.

Embodiment approach 3

[0030] Weigh 10 g of nano graphene, add 30 ml of acetone, ultrasonic dispersion for 30 min to obtain dispersion; add 100 g of waterborne polyurethane emulsion with a solid content of 30% in the dispersion, add 20 ml of absolute ethanol under high-speed stirring, continue to stir for 30 min, and obtain waterborne polyurethane / nano graphene emulsion; take an appropriate amount of the above emulsion on the PTFE plate, dry at 60 °C for 1 h, to obtain a biomimetic micro-patterned waterborne polyurethane / nano graphene coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com