Antibacterial mildew-proof transparent ABS master batch and preparation method thereof

A technology of antibacterial and antifungal, antibacterial and antifungal agent, applied in the field of polymer material modification, can solve the problems of transparency and antibacterial effect to be improved, and achieve the effect of efficient bactericidal performance and maintaining transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

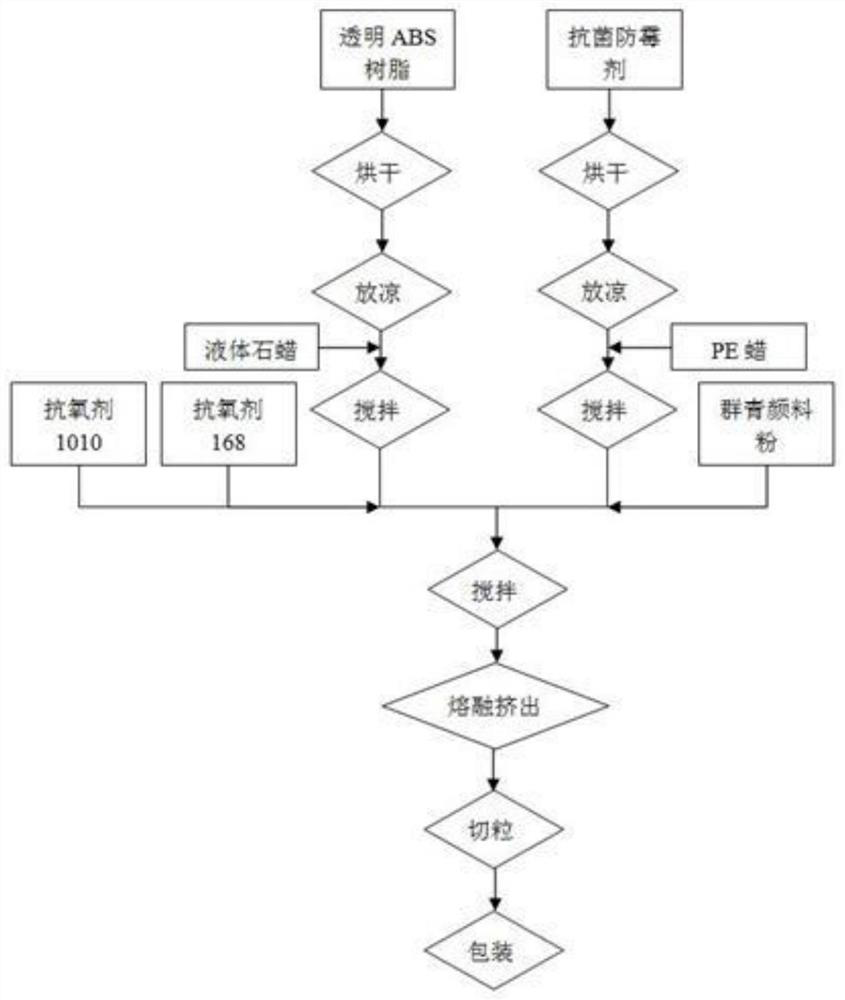

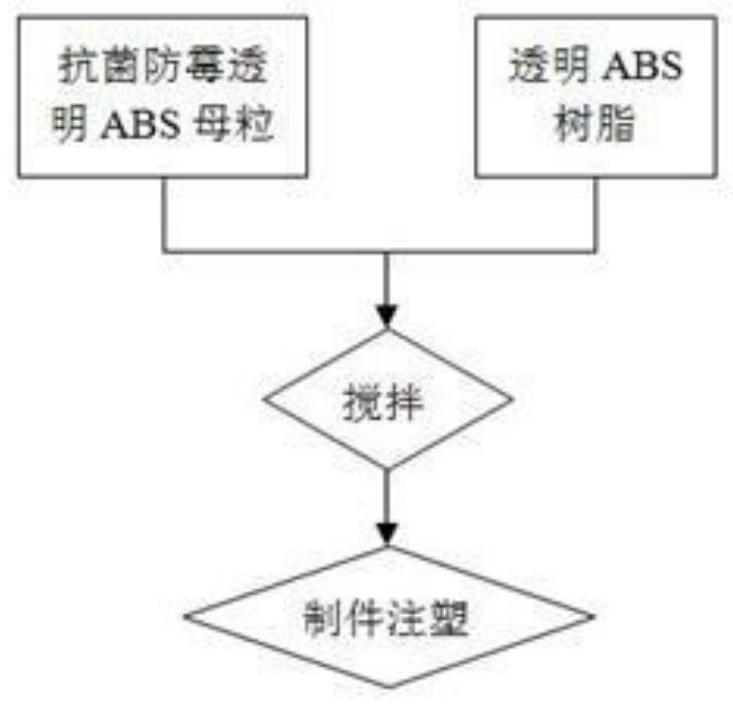

[0040] A preparation method of antibacterial and mildew-proof transparent ABS masterbatch, is characterized in that, comprises the following steps:

[0041] S1. Raw material pretreatment;

[0042] S2. Put the masterbatch raw material into the high-speed mixer according to the weight ratio and stir evenly;

[0043] S3. Control the temperature of each zone of the twin-screw extruder within the range of 160°C-200°C, keep the vacuum degree of the vacuum vent hole of the extruder within the range of -0.1MPa--0.09MPa, and add the mixed raw materials into the twin-screw extruder Melt blending in a screw extruder, extruded into strips, cooled, dried, pelletized, and packaged to complete the preparation of transparent ABS antibacterial and anti-mildew masterbatch.

[0044] In the present invention, the masterbatch is prepared by a method of melt blending.

[0045] Further, in step S1, it includes pre-treating the transparent ABS resin and the antibacterial and antifungal agent respec...

Embodiment 9

[0049] A preparation method of antibacterial and mildew-proof transparent ABS masterbatch, is characterized in that, comprises the following steps:

[0050] S1. Raw material pretreatment;

[0051]S2. Put the masterbatch raw material into the high-speed mixer according to the weight ratio and stir evenly;

[0052] S3. Control the temperature of each zone of the twin-screw extruder within the range of 160°C-200°C, keep the vacuum degree of the vacuum vent hole of the extruder within the range of -0.1MPa--0.09MPa, and add the mixed raw materials into the twin-screw extruder Melt blending in a screw extruder, extruded into strips, cooled, dried, pelletized, and packaged to complete the preparation of transparent ABS antibacterial and anti-mildew masterbatch.

[0053] In the present invention, the masterbatch is prepared by a method of melt blending.

[0054] Further, in step S1, it includes pre-treating the transparent ABS resin and the antibacterial and antifungal agent respect...

Embodiment 10

[0058] A preparation method of antibacterial and mildew-proof transparent ABS masterbatch, is characterized in that, comprises the following steps:

[0059] S1. Raw material pretreatment;

[0060] S2. Put the masterbatch raw material into the high-speed mixer according to the weight ratio and stir evenly;

[0061] S3. Control the temperature of each zone of the twin-screw extruder within the range of 160°C-200°C, keep the vacuum degree of the vacuum vent hole of the extruder within the range of -0.1MPa--0.09MPa, and add the mixed raw materials into the twin-screw extruder Melt blending in a screw extruder, extruded into strips, cooled, dried, pelletized, and packaged to complete the preparation of transparent ABS antibacterial and anti-mildew masterbatch.

[0062] In the present invention, the masterbatch is prepared by a method of melt blending.

[0063] Further, in step S1, it includes pre-treating the transparent ABS resin and the antibacterial and antifungal agent respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com