Material suction device for chemical raw material inspection

A material suction device and chemical raw material technology, which is applied in the direction of sampling device, transportation and packaging, and conveying bulk materials, etc., can solve the problems of low randomness of extraction, deviation, and slow manual sampling speed, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

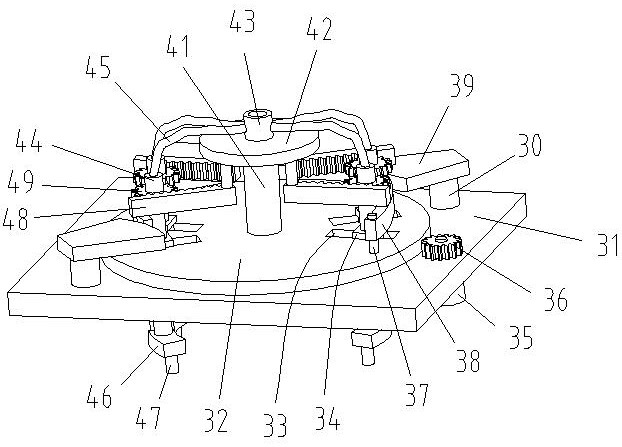

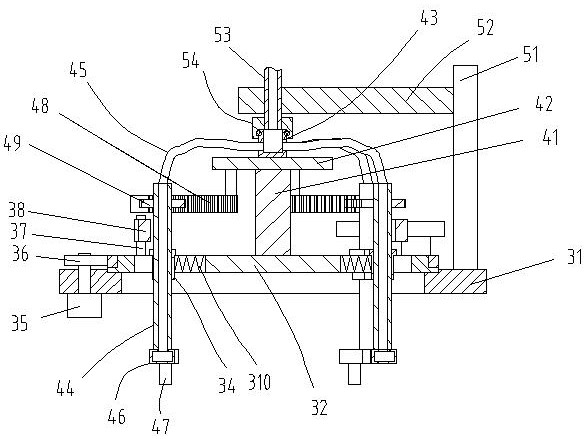

[0039] The invention discloses a suction device for testing chemical raw materials. The suction device 3 includes:

[0040] a plate 31;

[0041] A turntable 32, two groups of slide grooves 33 are arranged symmetrically on the turntable 32, and the turntable 32 is rotatably connected in the central hole of the flat plate 31;

[0042] A rotating device, the rotating device is used to control the rotation of the turntable 32 in the central hole of the flat plate 31;

[0043] Two groups of sliders 34, each group of sliders 34 are 2, the sliders 34 are arranged in the chute 33 one by one and can slide back and forth along the chute 33, the slider 34 is provided with vertical mounting holes;

[0044] Two groups of bronchus 44, the bronchus 44 is correspondingly fixed in the installation hole on the slider 34, and can rotate in the installation hole;

[0045] A support disc 42, the support disc 42 is coaxially fixed on the upper center of the turntable 32 through the support column...

Embodiment 2

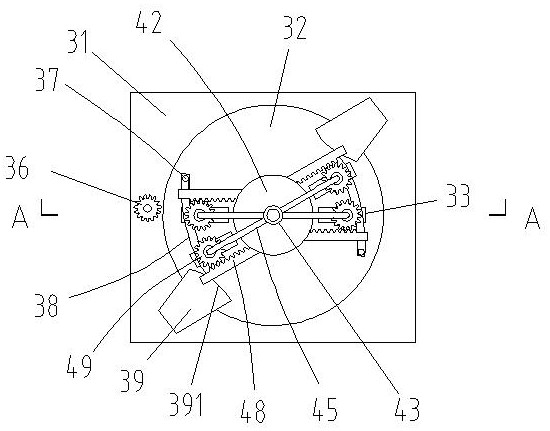

[0054] On the basis of Embodiment 1, the rotating device includes:

[0055] A second motor 35, the second motor 35 is fixed on one side of the flat plate 31;

[0056] A gear one 36, the gear one 36 is fixed on the main shaft of the motor two 35;

[0057] A gear ring, the gear ring is sleeved on the outer side of the turntable 32 and meshed with the first gear 36 .

[0058] Of course, the rotating device can adopt other rotating structures in the prior art.

Embodiment 3

[0060] On the basis of Embodiment 1, the lower end of each bronchus 44 is connected to the transition box 46, and the bottom of the transition box 46 is connected to a group of suction nozzles 47;

[0061] The outer side of each bronchus 44 is sleeved with a fixed gear 2 49 , and the lower side of the support disc 42 is fixedly connected with a rack 48 , and the rack 48 is meshed with the second gear 49 .

[0062] When the power unit control slider 34 reciprocally slides in the chute 33, the bronchus 44 is driven to rotate under the meshing effect of the rack 48 and the second gear 49, thereby driving the transition box 46 to rotate, which can increase the movement of the suction nozzle 47 range, thereby further improving the sampling effect. Due to the arc-shaped structure of the arc-shaped plate, the displacements of the two sliders sliding to the center of the circle are different. The greater the rotation of the arc-shaped plate, the greater the displacement gap between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com