Manufacturing method for environment-friendly degradable plastic packaging box

A technology of degrading plastics and production methods, which is applied in the direction of manufacturing tools, grinding machines, and grinding machine parts, etc., can solve the problems of increasing the workload of employees, reducing production efficiency, and low removal efficiency, so as to avoid uneven grinding and improve appearance Quality and the effect of reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

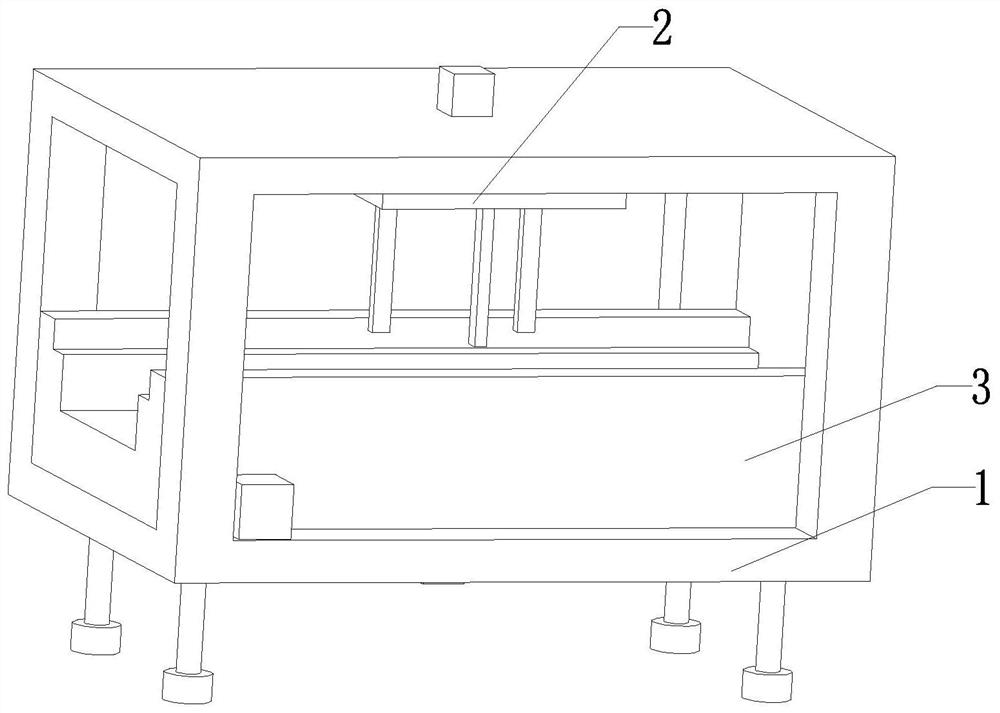

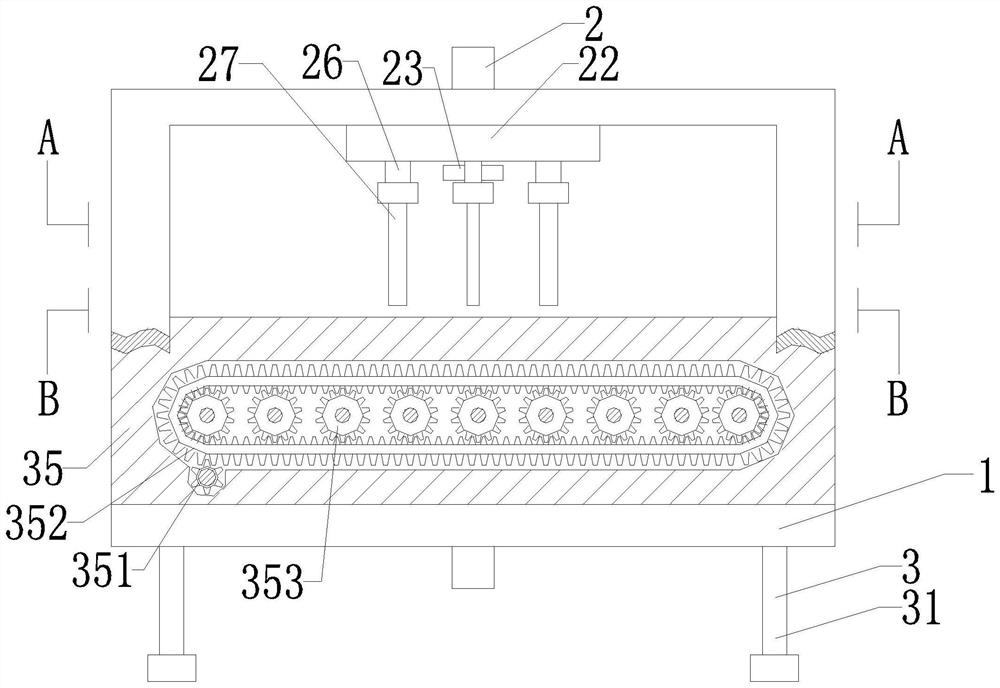

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

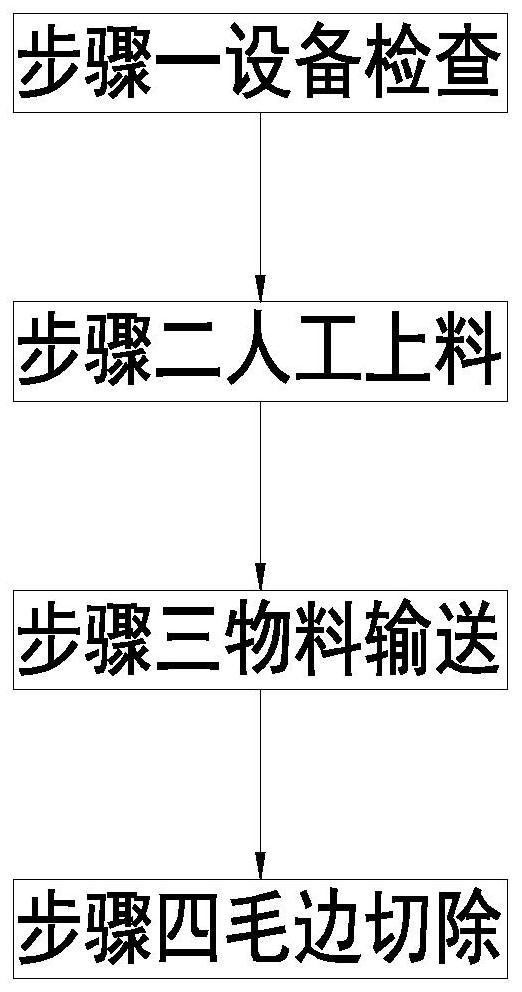

[0033] Such as Figure 1 to Figure 9As shown, a manufacturing method of an environment-friendly degradable plastic packaging box mainly includes the following steps:

[0034] Step 1: Equipment inspection: Check the operation of the equipment before using the environmentally friendly degradable plastic packaging box deburring equipment before deburring the plastic packaging box;

[0035] Step 2: Manual feeding: Manually place the plastic packaging box that needs to be deburred on the conveying plate 32, and adjust the position of the polishing bar 27 according to the outer diameter of the plastic packaging box, so as to achieve the purpose of manual loading;

[0036] Step 3: Material conveying: After completing the manual loading operation in Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com