Impingement cooling flow guide pipe laser welding-solid medium integrated forming method

A laser welding and draft tube technology, which is applied in the cooling of the engine, the cooling of the turbine/propulsion device, the engine components, etc., can solve the problems of wrinkling, broken wall thickness and unevenness of the draft tube, and avoid wrinkling. , low cost, simple mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

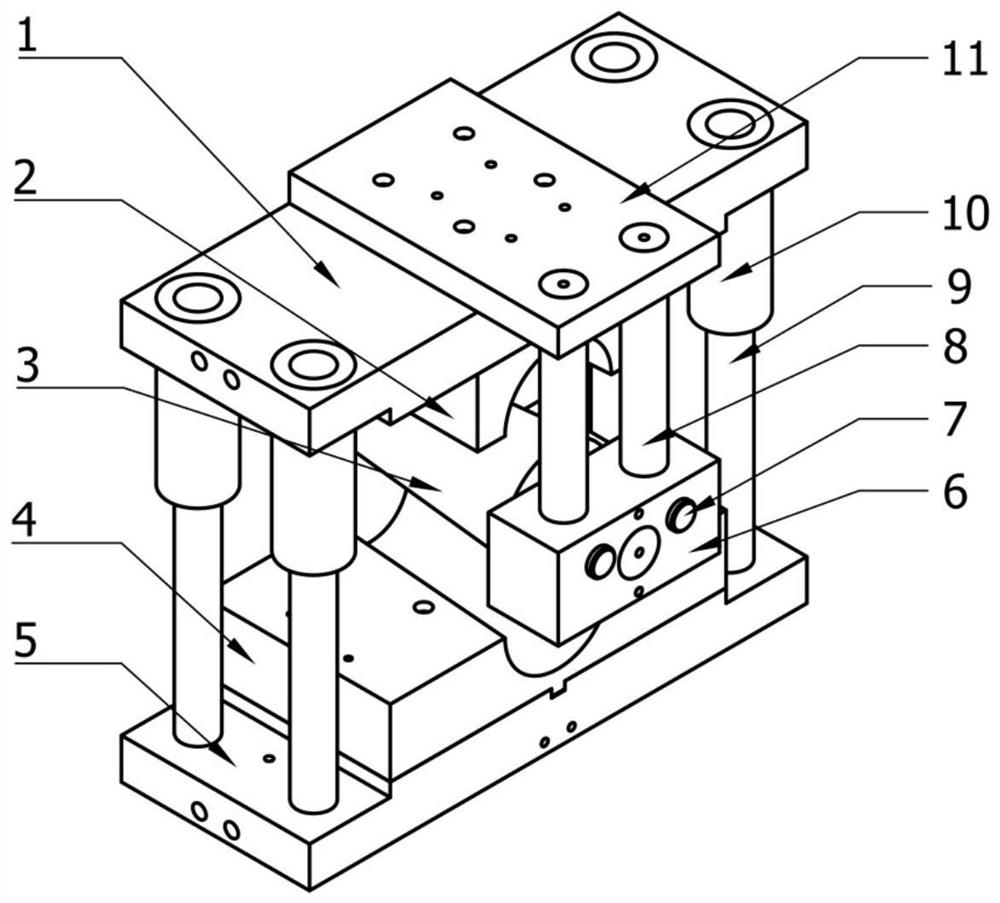

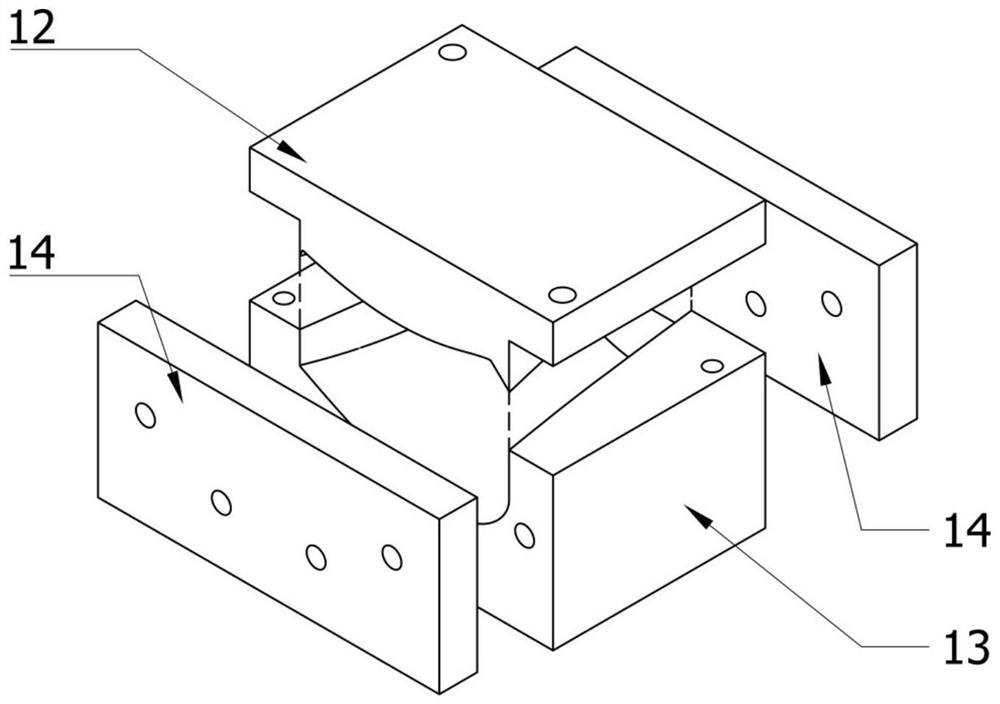

Examples

Embodiment 1

[0058] to manufacture as Figure 4 Take the diversion tube shown as an example, the material is GH3039, the wall thickness is 0.3mm, the cross-sectional area of the diversion tube along the length L direction gradually increases from the opening A on one side to the opening B on the other side, and the wall of the diversion tube There are several arrays of holes C, the perimeters of openings A and B on both sides are 195mm and 220mm respectively, and the length L of the draft tube is 80mm.

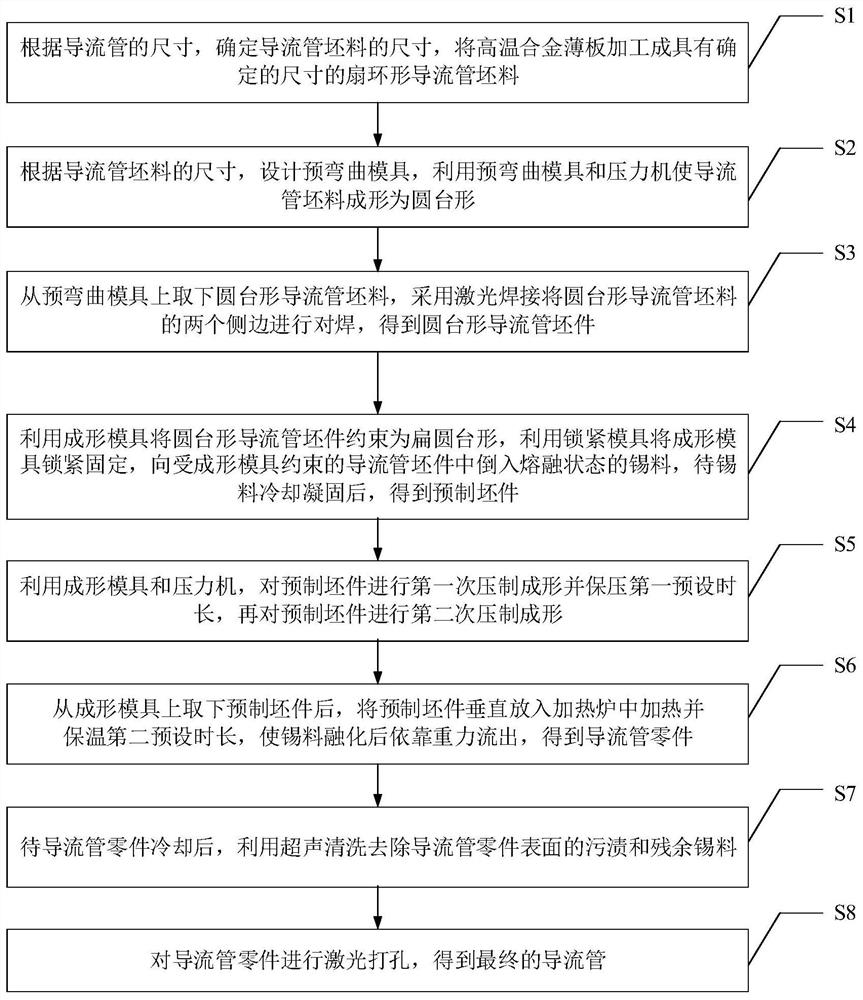

[0059] Such as Figure 4 The laser welding-solid medium integrated forming method of the flow guide tube specifically includes the following steps:

[0060] Step 1: According to the size of the draft tube, select an appropriate margin, and determine that the shape of the draft tube blank is a fan ring, such as Figure 5 As shown, the inner side length l of the fan ring 1 185mm, the outer length l 2 243mm, side length l 3 is 112mm; according to the size determined above, the GH3039 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com