Anti-overload torque sensor based on film sputtering

A torque sensor, anti-overload technology, applied in the direction of instruments, torque measurement, measuring devices, etc., can solve the problem of strain gauge life, stability, precision, low dynamic response and anti-vibration ability, narrow temperature range cannot meet the use requirements, Unable to meet the use requirements and other problems, to achieve the effect of good compactness, small internal stress and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

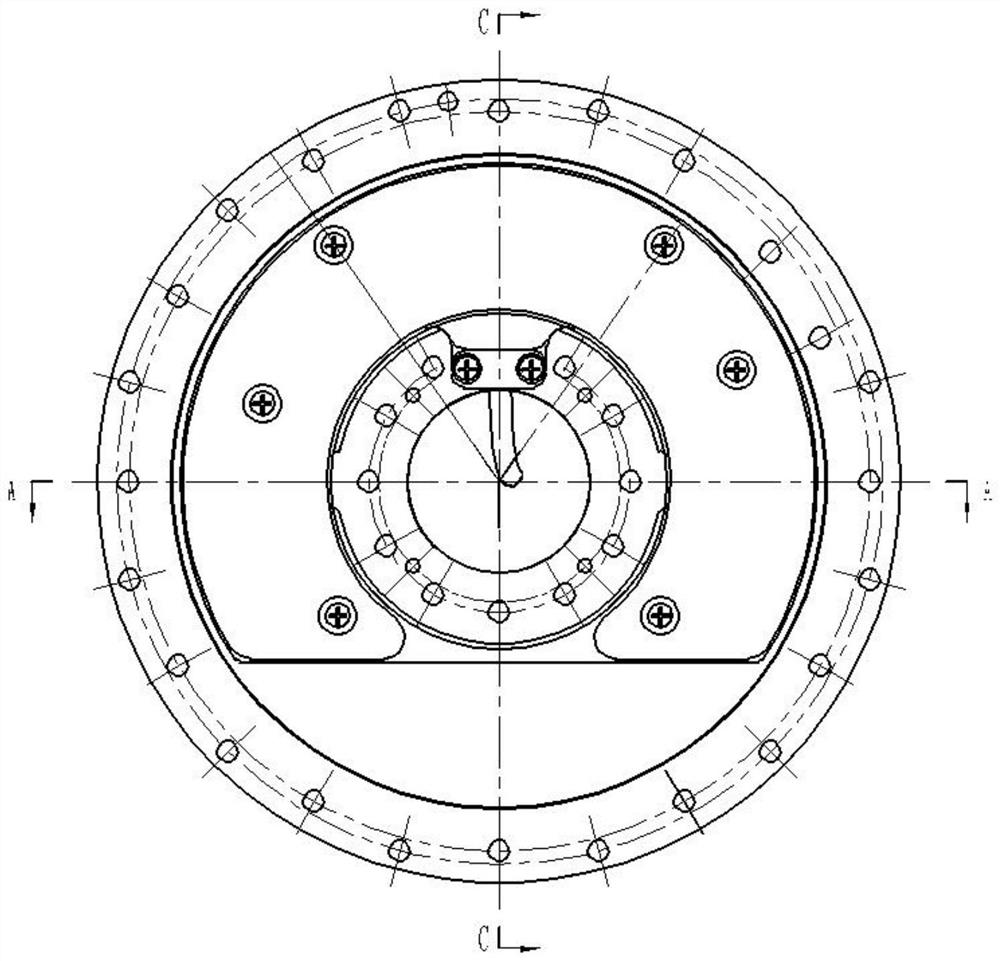

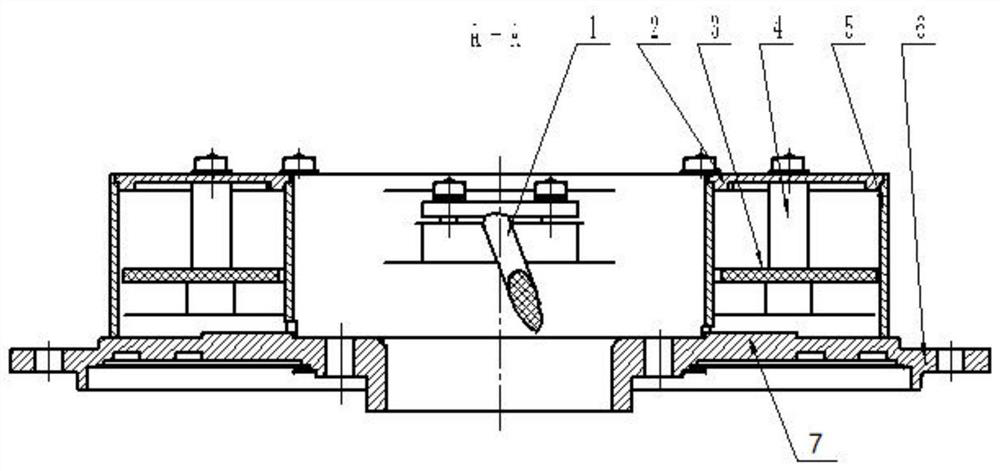

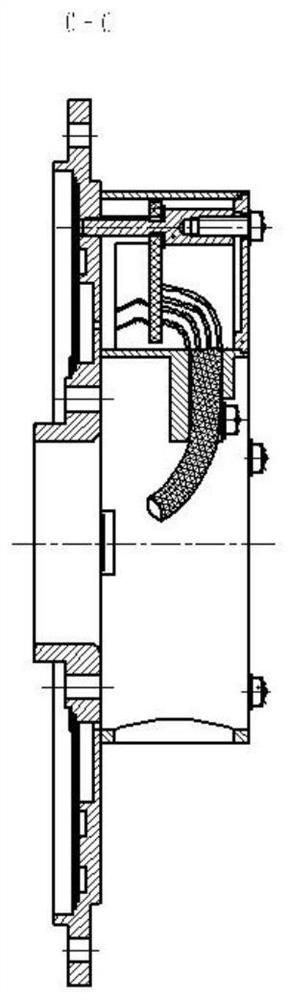

[0036] This embodiment provides a kind of anti-overload torque sensor based on thin film sputtering, see attached Figure 1-3 , including: output cable 1, upper cover plate 2, circuit board 3, pad column 4, housing 5, elastic body 6, strain beam 7 and film strain gauge 8;

[0037] The housing 5 is an annular housing, the upper end of the annular housing is open, and a connecting rod is installed at the lower end to connect the inner cylinder and the outer cylinder of the annular housing as a whole; in this embodiment, the housing 5 After being cut off by a plane parallel to its axis, the remaining C-shaped shell, the space formed by the cut off part is used for installing external components;

[0038] See attached Figure 4-5 , the elastic body 6 is an annular plate, and the annular plate is divided into three coaxial annular structures from the inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com