A method for deacidification and protection of concave-convex structure rubbings

A technology of concave-convex structure and deacidification, which is applied in the direction of recycling technology, physical treatment paper, chemical/biochemical treatment paper, etc., can solve the problems such as the destruction of the concave-convex shape structure on the surface of rubbings, the inability to remove the inert layer of rubbings, and the unsatisfactory deacidification effect, etc. , to achieve the effect of improving the deacidification effect, the deacidification effect is remarkable, and the deacidification process is mild

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

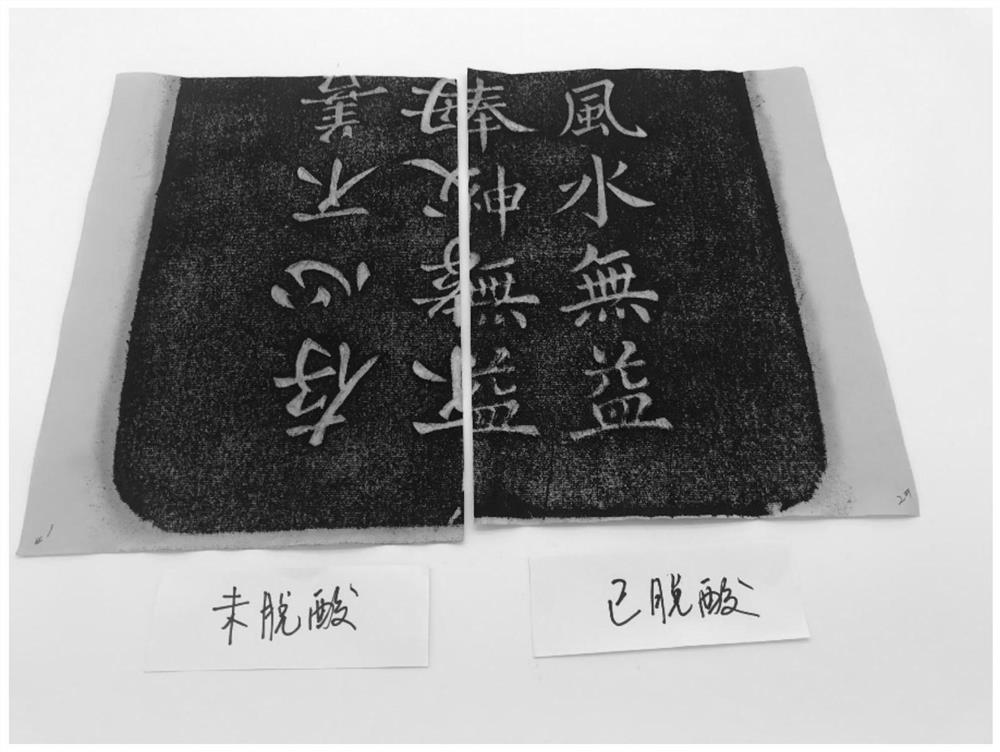

Image

Examples

Embodiment 1

[0029] Select acidified rubbings (rice paper material), use DC high-voltage power supply to generate plasma through dielectric barrier discharge in the plasma reaction chamber, use helium gas, the reaction voltage is 60V, and the current is 0.3A. The plasma generated by the gas discharge in the medium is brought out to generate a plasma flow. When a stable pulse current filament appears in the reaction chamber, start timing. The time for the plasma flow to process the rubbings is 3min. After the plasma treatment is completed, turn off the power. Take out the rubbings and put them in the deacidification room for later use.

[0030] First, 4wt% calcium hydroxide solution is ultrasonically atomized, and the atomized deacidification agent is passed into the deacidification chamber. After the surface of the rubbing is soaked by the atomized deacidification agent, the rubbing is taken out and placed in Dry naturally in the air, that is to complete the deacidification process of rubb...

Embodiment 2

[0047] The deacidifying agent in the embodiment 1 is adjusted to 3wt% magnesium hydroxide solution, and the rest are the same as the operation steps of the embodiment 1. The final deacidification effect is basically the same as in Example 1.

Embodiment 3

[0049] The deacidifying agent in embodiment 1 is adjusted to 8wt% calcium bicarbonate solution, and all the other are identical with embodiment 1 operation steps. The final deacidification effect is basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com