Method for warp knitting fabric by using PET cast film and slitting and stretching integrated machine

An all-in-one, cast film technology, applied in warp knitting, textiles and papermaking, single-component polyester rayon, etc., can solve the problems of unstable performance and poor product quality, and achieve good fabric quality and improved quality, and the effect of improving crystallization uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

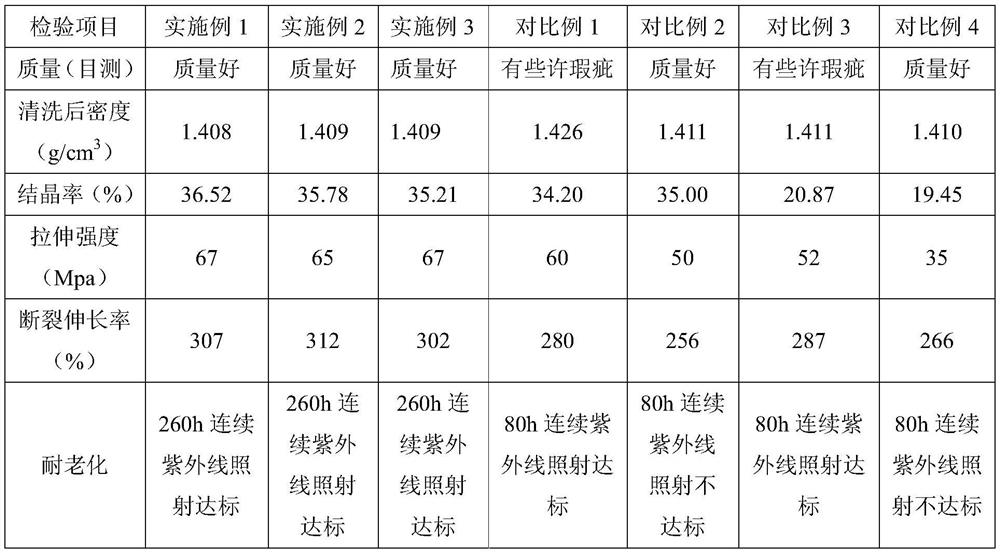

Examples

Embodiment 1

[0025] A kind of method that utilizes PET cast film and slitting and drawing all-in-one warp knitting fabric, comprises the steps:

[0026] (1) Recycling and cleaning: the waste PET polyester bottle is broken into 5cm fragments, cleaned by cleaning solution and rinsed with clear water, then centrifuged and dried, and then dried at low temperature to obtain PET recycled material; the cleaning solution is calculated in parts by weight, including: 30 parts of sodium hydroxide, 3 parts of diatomaceous earth, 7 parts of carboxymethyl cellulose, 50 parts of dodecyldimethylsulfopropyl betaine and 60 parts of deionized water;

[0027] (2) Prepare raw materials: by weight percentage, including the following components: PET recycled material 96%, tackifier (RX 3500) 3% and antioxidant (BASF antioxidant Irganox 1010) 1%;

[0028] (3) Crystallization drying: the raw materials are fed into the vacuum drum dryer through the feeder, heated to 150°C, and the heating time is 5h; The final mat...

Embodiment 2

[0041] A kind of method that utilizes PET cast film and slitting and drawing all-in-one warp knitting fabric, comprises the steps:

[0042] (1) Recycling and cleaning: Break the waste PET polyester bottle into 10cm pieces, after cleaning with cleaning solution and rinsing with clean water

[0043] Centrifugal drying, and then drying at low temperature to obtain PET recycled materials; the cleaning solution includes 20 parts by weight of sodium hydroxide, 4 parts of diatomaceous earth, 5 parts of carboxymethyl cellulose, dodecyl dimethyl 50 parts of sulfopropyl betaine and 80 parts of deionized water;

[0044] (2) Prepare raw materials: by weight percentage, including the following components: PET recycled material 98%, tackifier (RX 3500) 1% and antioxidant (BASF antioxidant Irganox 1010) 1%;

[0045] (3) Crystallization drying: the raw materials are fed into the vacuum drum dryer through the feeder, heated to 170°C, and the heating time is 4h; The final material is transpor...

Embodiment 3

[0051] A kind of method that utilizes PET cast film and slitting and drawing all-in-one warp knitting fabric, comprises the steps:

[0052] (1) Recycling and cleaning: the waste PET polyester bottle is broken into 5cm fragments, cleaned by cleaning solution and rinsed with clear water, then centrifuged and dried, and then dried at low temperature to obtain PET recycled material; the cleaning solution is calculated in parts by weight, including: 30 parts of sodium hydroxide, 3 parts of diatomaceous earth, 7 parts of carboxymethyl cellulose, 50 parts of dodecyldimethylsulfopropyl betaine and 60 parts of deionized water;

[0053] (2) Prepare raw materials: by weight percentage, including the following components: PET recycled material 98%, tackifier (RX 3500) 1.5% and antioxidant (BASF antioxidant Irganox 1010) 0.5%;

[0054] (3) Crystallization drying: the raw materials are fed into the vacuum drum dryer through the feeder, heated to 150°C, and the heating time is 5h; The final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com