Controlled cooling method for through-type high-temperature steel pipe quenching

A steel pipe and high-temperature technology, which is applied in the field of through-type high-temperature steel pipe quenching device and controlled cooling control, can solve the problems of poor circumferential cooling uniformity and unsatisfactory cooling rate control, etc., to achieve uniformity improvement, efficient recovery, and high efficiency The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

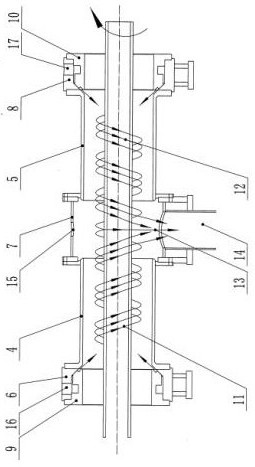

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

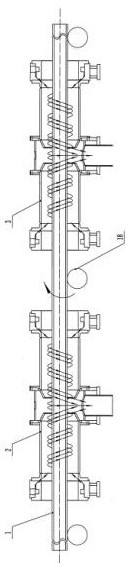

[0020] A through-type high-temperature steel pipe quenching device capable of effectively controlling cooling, comprising a V-shaped conveying roller table 18, on which a high-temperature steel pipe 1 is conveyed, and the V-shaped conveying roller table 18 conveying the high-temperature steel pipe 1 is Passing through the high-temperature section through-type cooling unit 2 and the low-temperature section through-type cooling unit 3 in sequence, the mechanical structure of the high-temperature section through-type cooling unit 2 is exactly the same as that of the low-temperature section through-type cooling unit 3; the high-temperature section through-type cooling unit 2 is composed of the left pipe section 4, the right pipe section 5, the left casing 6, the middle casing 7 and the right casing 8, and the left pipe section 4 and the right pipe section 5 are connected through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com