A kind of preparation method of high-brightness colored microspheres

A high-brightness, colorful technology, applied in the field of preparation of high-brightness colored microspheres, can solve the problems of poor reflective effect of glass beads at night, easy peeling of the color layer of glass beads, poor reflection effect of glass beads, etc., to achieve Excellent reflective effect, good adhesion, and mature production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of high-brightness colored microspheres, the preparation method is as follows:

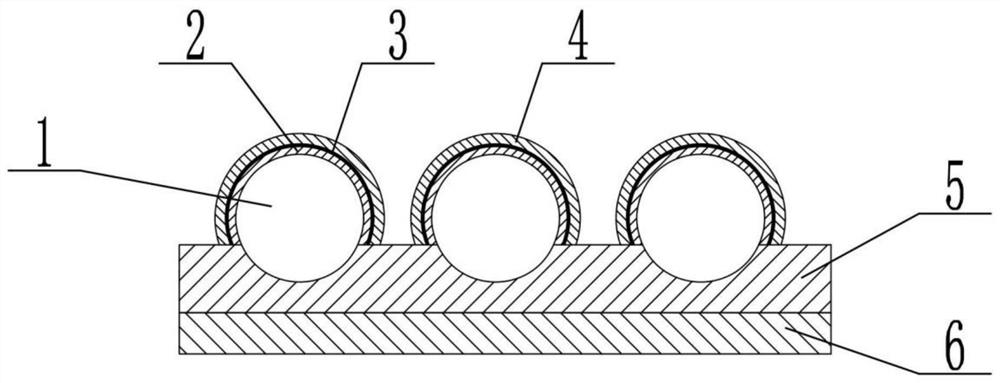

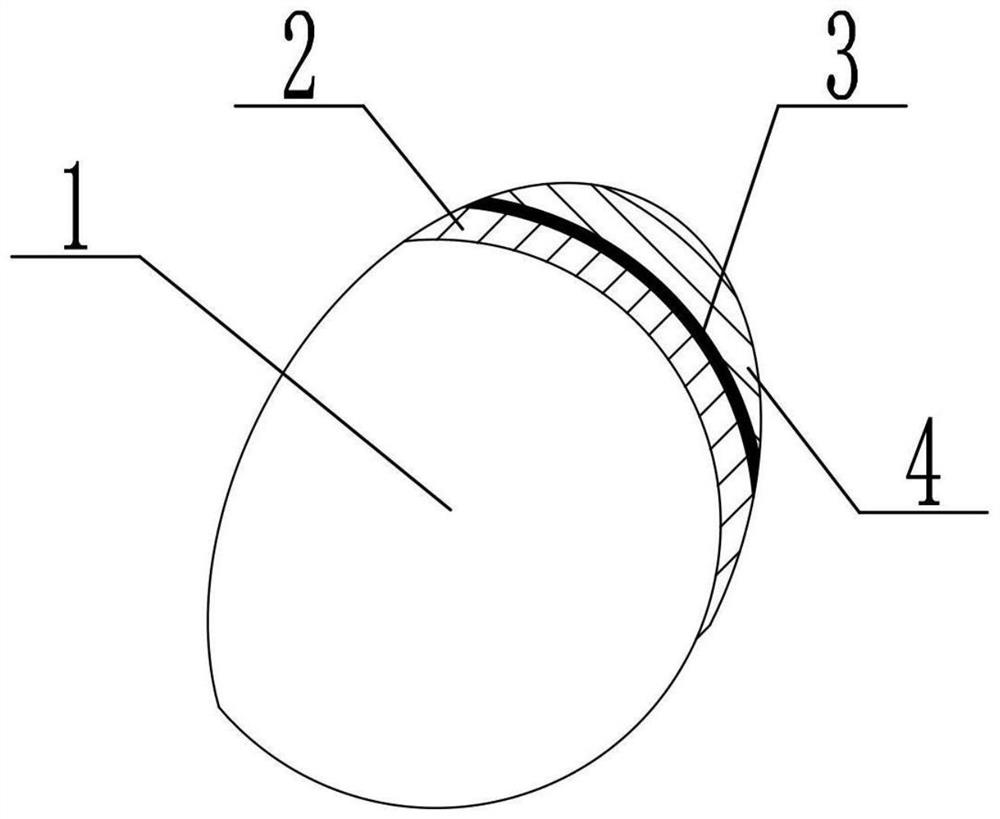

[0043] S1: Take the PET substrate 6 covered with PE film 5 on the surface, pretreat the PET substrate 6 with a guide roller at 150°C, then take the glass beads 1, and implant the glass beads 1 with a bead planting device the surface of the PE film 5, and make the glass microspheres 1 sink into the PE film 5, and the sinking range of the glass microspheres 1 is controlled at 30%;

[0044] S2: Take pigment A, polyester resin, epoxy resin A, isocyanate curing agent A, silane coupling agent, and ethyl acetate and mix them according to the weight ratio of 1:1:1.5:0.2:0.05:3.5 to obtain a mixed Coating A, using a dimple coating device to coat the mixed coating A on the surface of the glass microsphere 1, dry it at a temperature of 110°C, and place it at a temperature of 70°C for aging for 48 hours to form a color layer 2;

[0045] S3: The color layer 2 is placed in an enviro...

Embodiment 2

[0058] A preparation method of high-brightness colored microspheres, the preparation method is as follows:

[0059] S1: Take the PET substrate 6 covered with the PE film 5 on the surface, pretreat the PET substrate 6 with a guide roller at 230°C, then take the glass beads 1, and implant the glass beads 1 with a bead planting device the surface of the PE film 5, and make the glass microspheres 1 sink into the PE film 5, and the sinking range of the glass microspheres 1 is controlled at 50%;

[0060] S2: Take pigment A, polyester resin, epoxy resin A, isocyanate curing agent A, silane coupling agent, and ethyl acetate and mix them according to the weight ratio of 1:1:1.5:0.2:0.05:3.5 to obtain a mixed Coating A, using a dimple coating device to coat the mixed coating A on the surface of the glass microsphere 1, dry it at a temperature of 150°C, and place it at a temperature of 70°C for aging for 48 hours to form a color layer 2;

[0061] S3: Place the color layer 2 in an enviro...

Embodiment 3

[0074] A preparation method of high-brightness colored microspheres, the preparation method is as follows:

[0075] S1: Take the PET substrate 6 covered with PE film 5 on the surface, pretreat the PET substrate 6 with a guide roller at 190°C, then take the glass beads 1, and implant the glass beads 1 with a bead planting device the surface of the PE film 5, and make the glass microspheres 1 sink into the PE film 5, and the sinking range of the glass microspheres 1 is controlled at 40%;

[0076] S2: Take pigment A, polyester resin, epoxy resin A, isocyanate curing agent A, silane coupling agent, and ethyl acetate and mix them according to the weight ratio of 1:1:1.5:0.2:0.05:3.5 to obtain a mixed Coating A, using a dimple coating device to coat the mixed coating A on the surface of the glass microsphere 1, dry it at a temperature of 130°C, and place it at a temperature of 70°C for aging for 48 hours to form a color layer 2;

[0077] S3: The color layer 2 is placed in an enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com