Preparation method of high-brightness colored microspheres

A high-brightness and color technology, applied in the field of preparation of high-brightness colored microspheres, can solve the problems of glass microbeads with poor night-time reflective effect, low retro-reflection performance, solvent intolerant, etc., and achieve excellent color light effect and retro-reflection performance. The effect of improving and improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of high-brightness colored microspheres, the preparation method is as follows:

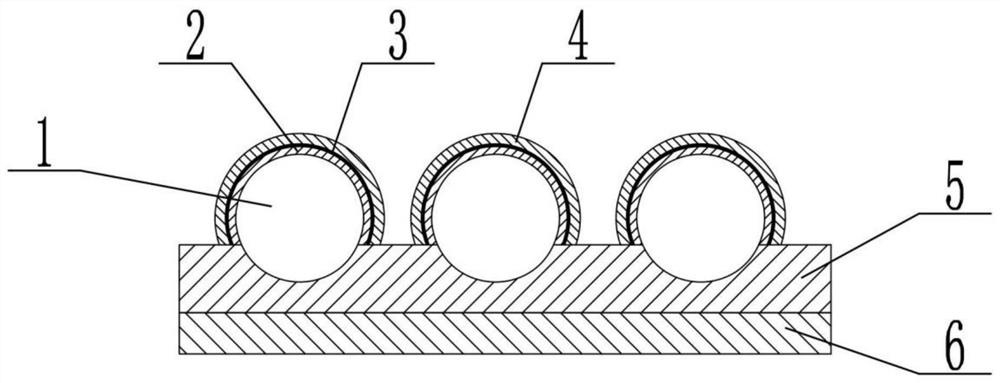

[0043] S1: Take the PET substrate 6 covered with PE film 5 on the surface, pretreat the PET substrate 6 with a guide roller at 150°C, then take the glass beads 1, and implant the glass beads 1 with a bead planting device the surface of the PE film 5, and make the glass microspheres 1 sink into the PE film 5, and the sinking range of the glass microspheres 1 is controlled at 30%;

[0044] S2: Take pigment A, polyester resin, epoxy resin A, isocyanate curing agent A, silane coupling agent, and ethyl acetate and mix them according to the weight ratio of 1:1:1.5:0.2:0.05:3.5 to obtain a mixed Coating A, using a dimple coating device to coat the mixed coating A on the surface of the glass microsphere 1, dry it at a temperature of 110°C, and place it at a temperature of 70°C for aging for 48 hours to form a color layer 2;

[0045] S3: The color layer 2 is placed in an enviro...

Embodiment 2

[0058] A preparation method of high-brightness colored microspheres, the preparation method is as follows:

[0059] S1: Take the PET substrate 6 covered with the PE film 5 on the surface, pretreat the PET substrate 6 with a guide roller at 230°C, then take the glass beads 1, and implant the glass beads 1 with a bead planting device the surface of the PE film 5, and make the glass microspheres 1 sink into the PE film 5, and the sinking range of the glass microspheres 1 is controlled at 50%;

[0060] S2: Take pigment A, polyester resin, epoxy resin A, isocyanate curing agent A, silane coupling agent, and ethyl acetate and mix them according to the weight ratio of 1:1:1.5:0.2:0.05:3.5 to obtain a mixed Coating A, using a dimple coating device to coat the mixed coating A on the surface of the glass microsphere 1, dry it at a temperature of 150°C, and place it at a temperature of 70°C for aging for 48 hours to form a color layer 2;

[0061] S3: Place the color layer 2 in an enviro...

Embodiment 3

[0074] A preparation method of high-brightness colored microspheres, the preparation method is as follows:

[0075] S1: Take the PET substrate 6 covered with PE film 5 on the surface, pretreat the PET substrate 6 with a guide roller at 190°C, then take the glass beads 1, and implant the glass beads 1 with a bead planting device the surface of the PE film 5, and make the glass microspheres 1 sink into the PE film 5, and the sinking range of the glass microspheres 1 is controlled at 40%;

[0076] S2: Take pigment A, polyester resin, epoxy resin A, isocyanate curing agent A, silane coupling agent, and ethyl acetate and mix them according to the weight ratio of 1:1:1.5:0.2:0.05:3.5 to obtain a mixed Coating A, using a dimple coating device to coat the mixed coating A on the surface of the glass microsphere 1, dry it at a temperature of 130°C, and place it at a temperature of 70°C for aging for 48 hours to form a color layer 2;

[0077] S3: The color layer 2 is placed in an enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com