Method for synchronously removing heavy metals and nitrates in mine wastewater and reactor

A mine wastewater and reactor technology, which is applied in mining wastewater treatment, chemical instruments and methods, and water pollutants, etc., can solve problems such as excessive heavy metals and nitrate pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

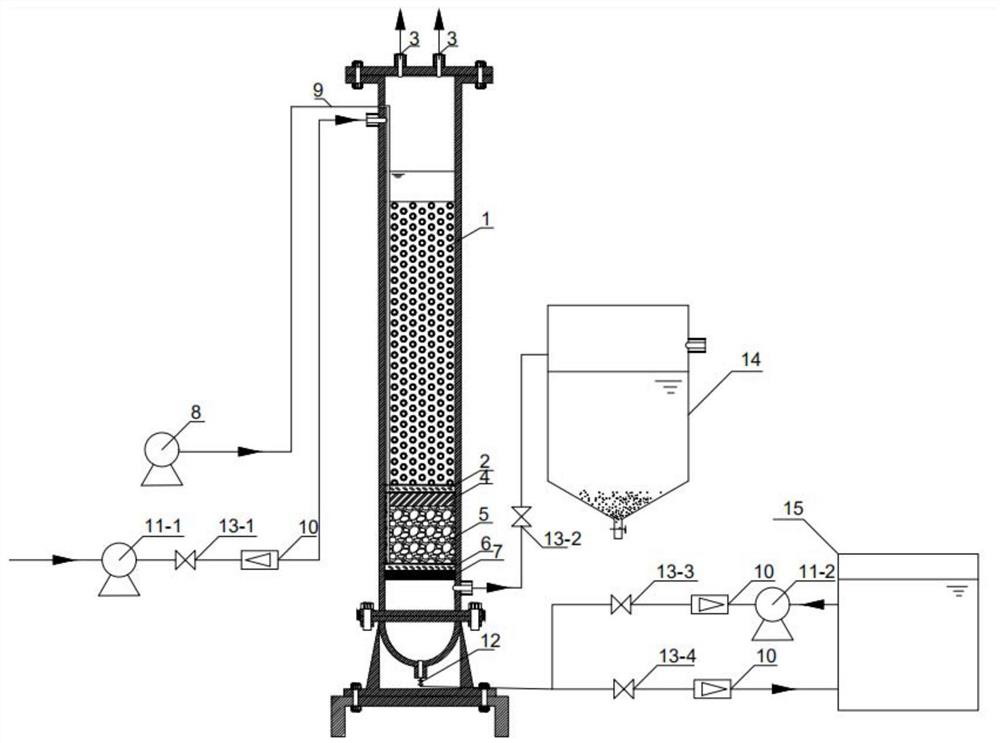

Method used

Image

Examples

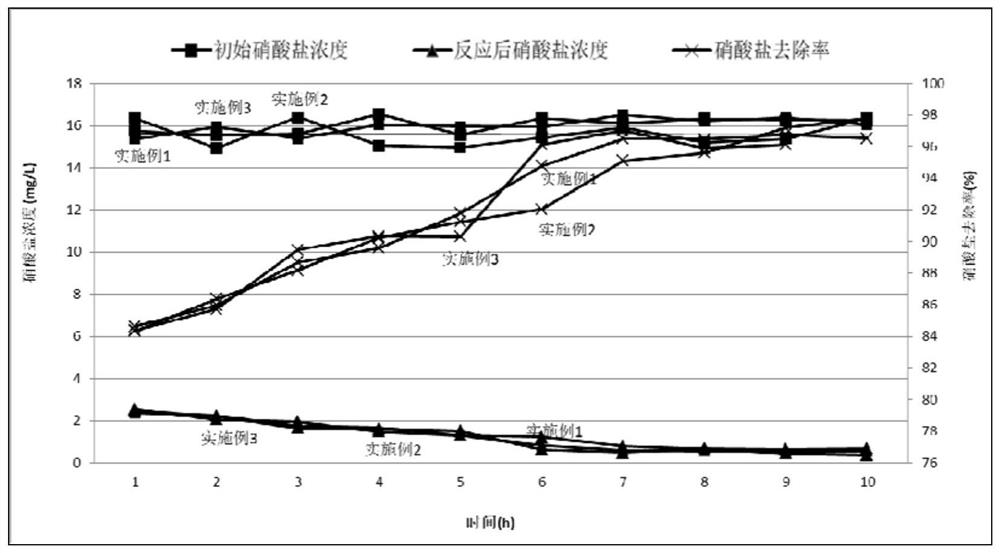

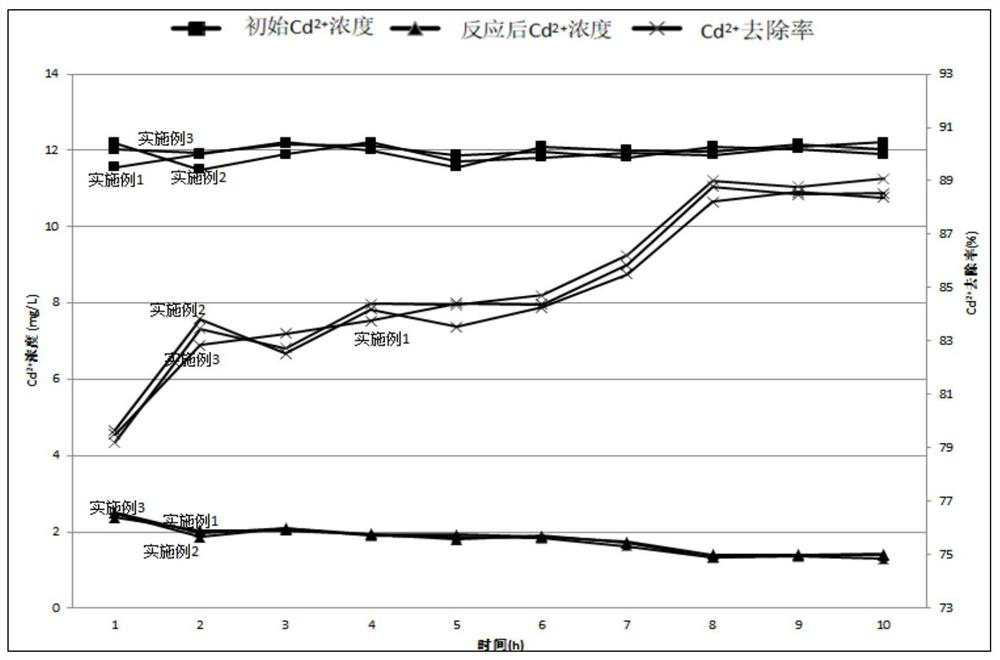

Embodiment 1

[0077] The mine waste water to be treated in this embodiment comes from a certain mining area waste water in Shaanxi Province, artificially replenishing nitrate and heavy metal (Cd2+ , Pb 2+ 、Ni 2+ ), follow the technical scheme of the present invention, carry out advanced treatment to water body, comprise the following steps:

[0078] Step 1, sludge enrichment and domestication:

[0079] Take 10L of mine wastewater to be treated and FJY culture solution according to the volume ratio of 3:1, mix them evenly, place them in a constant temperature incubator (25-30°C) for enrichment culture, and inject 7L / min nitrogen gas into the reactor 4 times a day , 5 minutes each time, during the enrichment culture process, 7 days is a culture cycle, replace half of the supernatant with FJY culture medium, using a shaker with a rotation speed of 140r / min, after 3 weeks of enrichment, when the nitrate removal rate Above 70%, Cd 2+ , Pb 2+ 、Ni 2+ When the removal rate is above 60%, it ind...

Embodiment 2

[0105] The mine waste water to be treated in this embodiment comes from a certain mining area waste water in Shaanxi Province, artificially replenishing nitrate and heavy metal (Cd 2+ , Pb 2+ 、Ni 2+ ), follow the technical scheme of the present invention, carry out advanced treatment to water body, comprise the following steps:

[0106] Step 1, sludge enrichment and domestication:

[0107] Take 10L of mine wastewater to be treated and FJY culture solution according to the volume ratio of 4:1, mix them evenly, place them in a constant temperature incubator (25-30°C) for enrichment culture, and inject 5L / min nitrogen into the reactor 4 times a day , 5 minutes each time, during the enrichment culture process, 7 days is a culture cycle, replace half of the supernatant with FJY culture medium, using a shaker with a rotation speed of 130r / min, after 2 weeks of enrichment, when the nitrate removal rate Above 70%, Cd 2+ , Pb 2+ 、Ni 2+ When the removal rate is above 60%, it indic...

Embodiment 3

[0131] The mine waste water to be treated in this embodiment comes from a certain mining area waste water in Shaanxi Province, artificially replenishing nitrate and heavy metal (Cd 2+ , Pb 2+ 、Ni 2+ ), follow the technical scheme of the present invention, carry out advanced treatment to water body, comprise the following steps:

[0132] Step 1, sludge enrichment and domestication:

[0133] Take 10L of mine wastewater to be treated and FJY culture solution according to the volume ratio of 2:1, mix them evenly, place them in a constant temperature incubator (25-30°C) for enrichment culture, and inject 8L / min nitrogen gas into the reactor 4 times a day , 5 minutes each time, during the enrichment culture process, 7 days is a culture cycle, replace half of the supernatant with FJY culture medium, use a shaker with a rotation speed of 120r / min, and after 3 weeks of enrichment, when the nitrate removal rate Above 70%, Cd 2+ , Pb 2+ 、Ni 2+ When the removal rate is above 60%, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com