Polycarbonate material with excellent transparent light diffusion function and preparation method thereof

A polycarbonate and light diffusion technology, applied in the field of polycarbonate materials and their preparation, can solve the problems of dazzling, limited lighting area, etc., and achieve the effect of improving yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

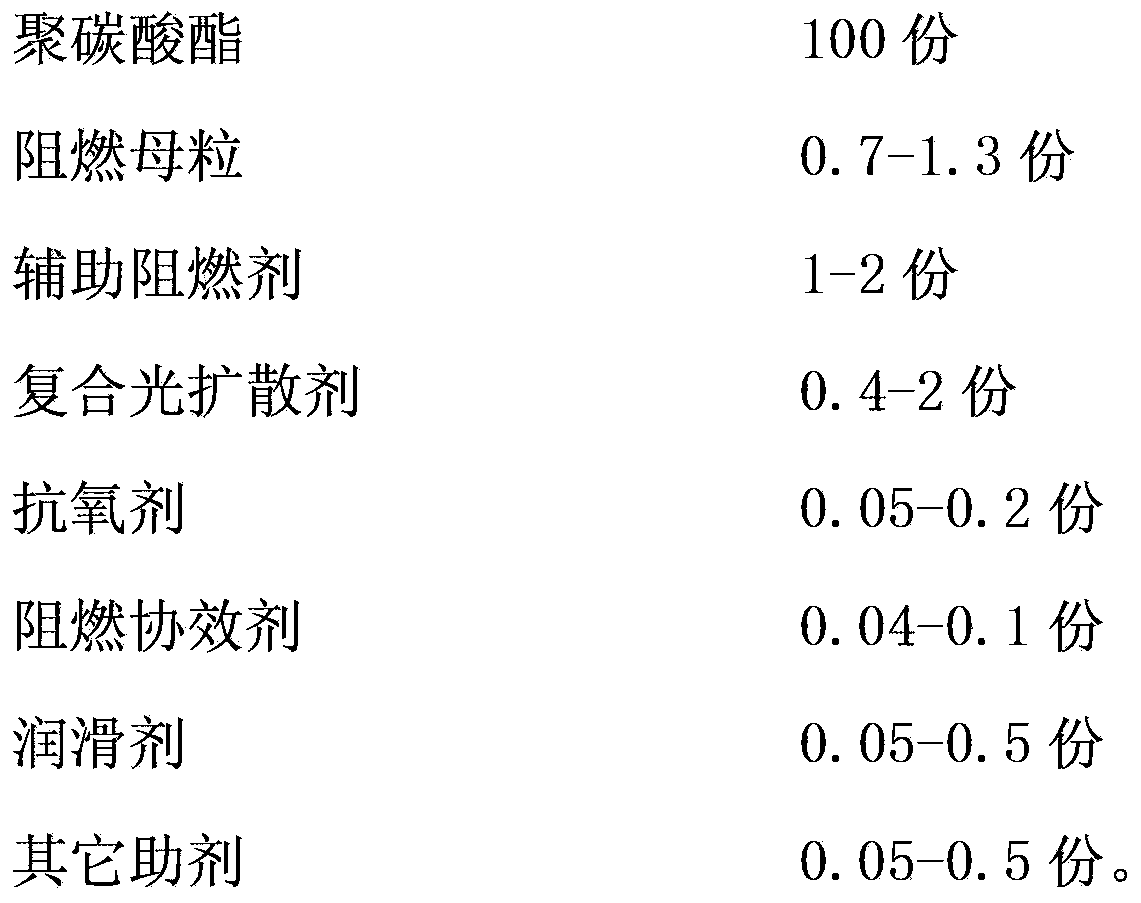

[0034] A method for preparing a polycarbonate material with good transparent light diffusion function. The first step is to melt and blend sulfonate flame retardants and silicone flame retardants with PC resin, and extrude them through a twin-screw extruder Granulation molding, the temperature setting range is 220°C-250°C, and the flame retardant masterbatch is made; the second step is mainly PC, adding composite light diffusing agent, flame retardant masterbatch, antioxidant, and flame retardant synergist , lubricants and other additives are further melted and blended in a twin-screw extruder with a set temperature of 250°C-280°C, extruded and granulated.

[0035] For the twin-screw extruder, the aspect ratio of the screw is 25-50:1, the screw speed is set at 200-600 rpm in the first step, and the screw speed is set at 200-600 rpm in the second step.

[0036] The dosage ratio relationship of each embodiment component is shown in Table 1. Wherein the dosage units are parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com