A graphitized carbon-supported nano-zero-valent iron material and its preparation method and application

A nano-zero-valent iron and graphitized carbon technology, which is applied in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve the large-scale industrial production of unfavorable materials, complex operation process and synthesis conditions, waste water Deal with problems that need to be further improved to achieve the effect of increasing stability and reusability, increasing stability and durability, and easy adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

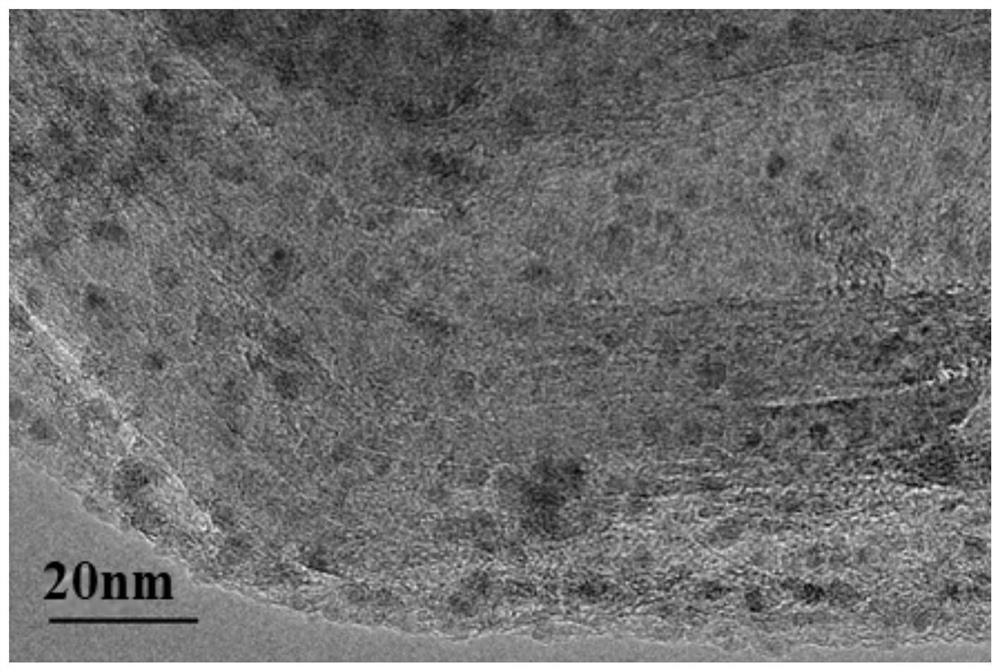

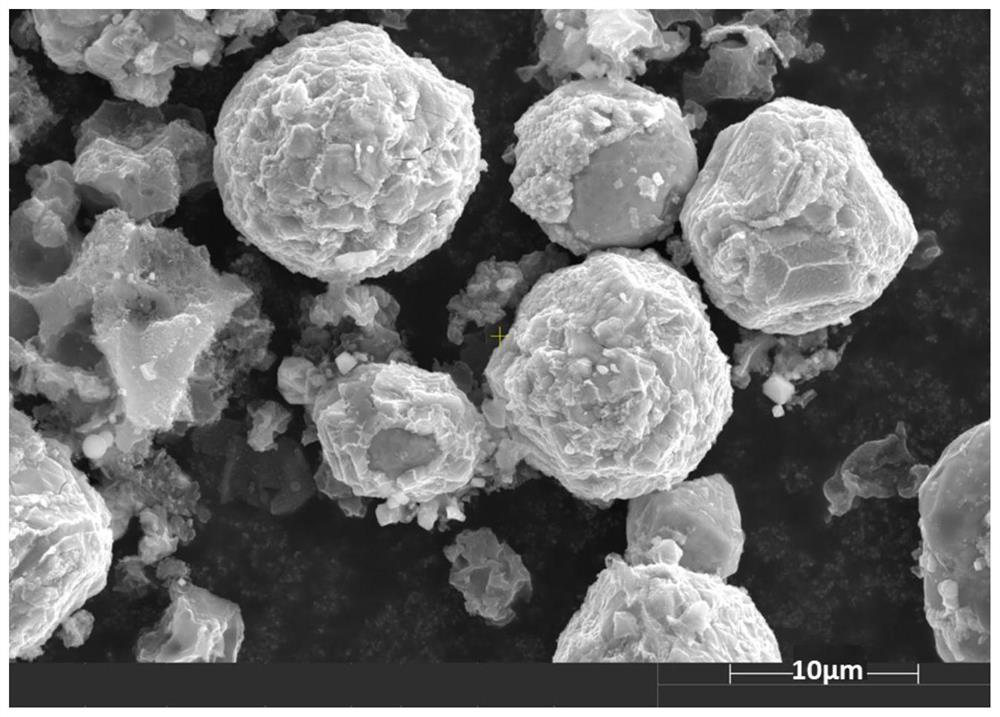

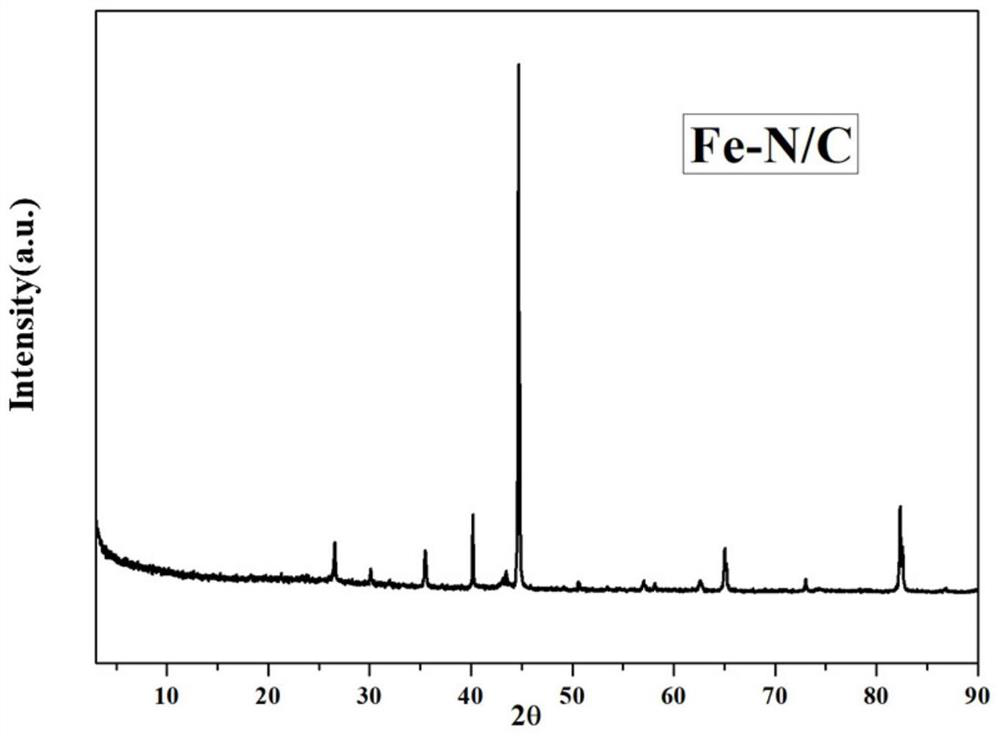

[0045] A preparation method of graphitized carbon-supported nanometer zero-valent iron material, comprising the following steps:

[0046] (1) Ferrous acetate and 2-aminoterephthalic acid are placed in a ball mill reactor with a mass ratio of 3:1;

[0047] (2) Add a zirconia grinding medium with a diameter of 5 mm to the ball mill reactor, adjust the rotating speed of the ball mill to 300 rpm, add 1 mL / g of ethylene glycol solution and grind for 5 hours to obtain a polymer material;

[0048] (3) Put the polymer material in a tube furnace and heat it up to 800°C at a heating rate of 10°C / min under a nitrogen atmosphere; pyrolyze for 3 hours and cool to obtain graphitized carbon-loaded nano-zero-valent iron material .

Embodiment 2

[0050] A preparation method of graphitized carbon-supported nanometer zero-valent iron material, comprising the following steps:

[0051] (1) Ferric sulfate and 2-aminoterephthalic acid are placed in a ball mill reactor at a mass ratio of 2:1;

[0052] (2) Add an alumina grinding medium with a diameter of 5 mm to the ball mill reactor, adjust the rotating speed of the ball mill to 350 rpm, add 1 mL / g of dimethylformamide solution and grind for 4 hours to obtain a polymer material;

[0053] (3) Put the polymer material in a tube furnace and heat it to 900°C at a heating rate of 10°C / min in an argon atmosphere; pyrolyze it for 3 hours and cool it down to obtain graphitized carbon-supported nano-zero-valent iron Material.

Embodiment 3

[0055] A preparation method of graphitized carbon-supported nanometer zero-valent iron material, comprising the following steps:

[0056] (1) ferric chloride and 2-aminoterephthalic acid are placed in a ball mill reactor with a mass ratio of 4:1;

[0057] (2) add the agate ball grinding medium of diameter 10mm in the ball mill reactor, adjust the rotating speed of ball mill to be 290rpm, add the ethylene glycol solution of 1mL / g and grind for 5 hours to obtain polymer material;

[0058] (3) Put the polymer material in a tube furnace and heat it to 750°C at a heating rate of 5°C / min under a nitrogen atmosphere; pyrolyze for 3 hours and cool to obtain graphitized carbon-loaded nano-zero-valent iron material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com