Mesoporous manganese-based composite oxide, preparation method and application thereof

A composite oxide and mesoporous manganese-based technology, applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve the problems of complex preparation process and limited industrial application, and achieve simple preparation method, low cost, The effect of stabilizing catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Weigh 0.13g of nickel chloride and 1.26g of manganese chloride and add them to 36.8g of ethanol successively, stir until nickel chloride and manganese chloride are all dissolved, and obtain nickel and manganese mixed ethanol solution; wherein nickel, manganese and ethanol The molar ratio is 0.1:1:80.

[0040] (2) Take by weighing 0.51g triethylamine and 1.0g sodium hydroxide respectively and join in 103.5g ethanol, stir until sodium hydroxide is all dissolved, obtain the organic solution of sodium hydroxide; Wherein triethylamine, sodium hydroxide and ethanol The molar ratio is 0.2:1:90.

[0041](3) Add the sodium hydroxide organic solution of step (2) to the nickel and manganese ethanol solution in step (1), stir for 7 hours at 20°C to form a turbid solution, which is centrifuged, washed, and dried to obtain nickel Manganese composite oxide precursor; the molar ratio of manganese added to inorganic alkali sodium hydroxide is 1:2.5.

[0042] (4) Put the nickel-man...

Embodiment 2

[0044] (1) Take by weighing 0.65g cobalt chloride and 1.26g manganese chloride and join in 89.6g methanol successively, stir until cobalt chloride and manganese chloride all dissolve, obtain cobalt and manganese methanol solution; wherein cobalt, manganese and methanol The molar ratio is 0.5:1:280.

[0045] (2) Weigh 1.89g of ethylenediamine and 1.96g of potassium hydroxide and add them to 123.2g of methanol, and stir until the potassium hydroxide is completely dissolved to obtain an organic solution of potassium hydroxide; wherein ethylenediamine, potassium hydroxide and methanol The molar ratio is 0.9:1:110.

[0046] (3) Add the potassium hydroxide organic solution in step (2) to the cobalt and manganese methanol solution in step (1), stir at 40°C for 5h to form a turbid solution, centrifuge, wash, and dry to obtain cobalt Manganese composite oxide precursor; the molar ratio of manganese to potassium hydroxide is 1:3.5.

[0047] (4) Put the cobalt-manganese composite oxide...

Embodiment 3

[0049] (1) Take by weighing 0.95g zinc nitrate and 1.26g manganese chloride and join in 146gDMF successively, stir until zinc nitrate and manganese chloride all dissolve, obtain the DMF solution of zinc and manganese; Wherein the mol ratio of zinc, manganese and DMF is 0.5:1:200.

[0050] (2) Take by weighing 2.92g n-butylamine and 1.6g sodium hydroxide respectively and join in 175.2gDMF, stir until sodium hydroxide is all dissolved, obtain the organic solution of sodium hydroxide; Wherein n-butylamine, sodium hydroxide and DMF The molar ratio is 1:1:60.

[0051] (3) Add the sodium hydroxide organic solution in step (2) to the zinc and manganese DMF solution in step (1), stir for 4 hours at 50°C to form a turbid solution, centrifuge, wash, and dry to obtain zinc Manganese composite oxide precursor; the molar ratio of manganese to inorganic alkali sodium hydroxide is 1:4.

[0052] (4) Put the zinc-manganese composite oxide precursor obtained in step (3) in a tube furnace and ...

PUM

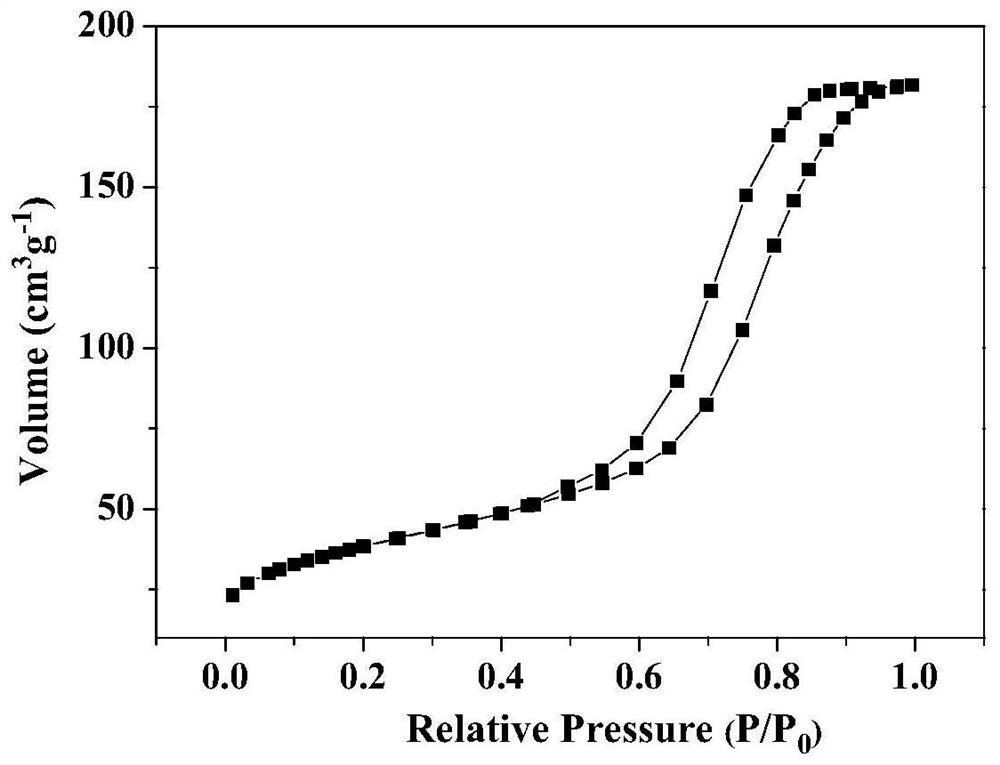

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com