Supported catalyst, preparation method and application thereof

A supported catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxime preparation, etc., can solve the problem that it is difficult to stabilize the selectivity of cyclohexanone oxime, it cannot be widely used, and the product needs to be separated, etc. problems, achieve the effects of reducing solid and liquid waste discharge, environmental friendliness, and reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of a supported catalyst, comprising the following steps:

[0032] 1) placing the carrier in deionized water, dispersing and stirring evenly to obtain an aqueous solution dispersed with the carrier;

[0033] 2) dissolving the Pt precursor in deionized water, and adding it to the aqueous solution dispersed with the carrier obtained in step 1), fully stirring, impregnating, separating, washing, vacuum drying, and calcining in a hydrogen atmosphere for 2-6 hours, Prepare the first catalyst.

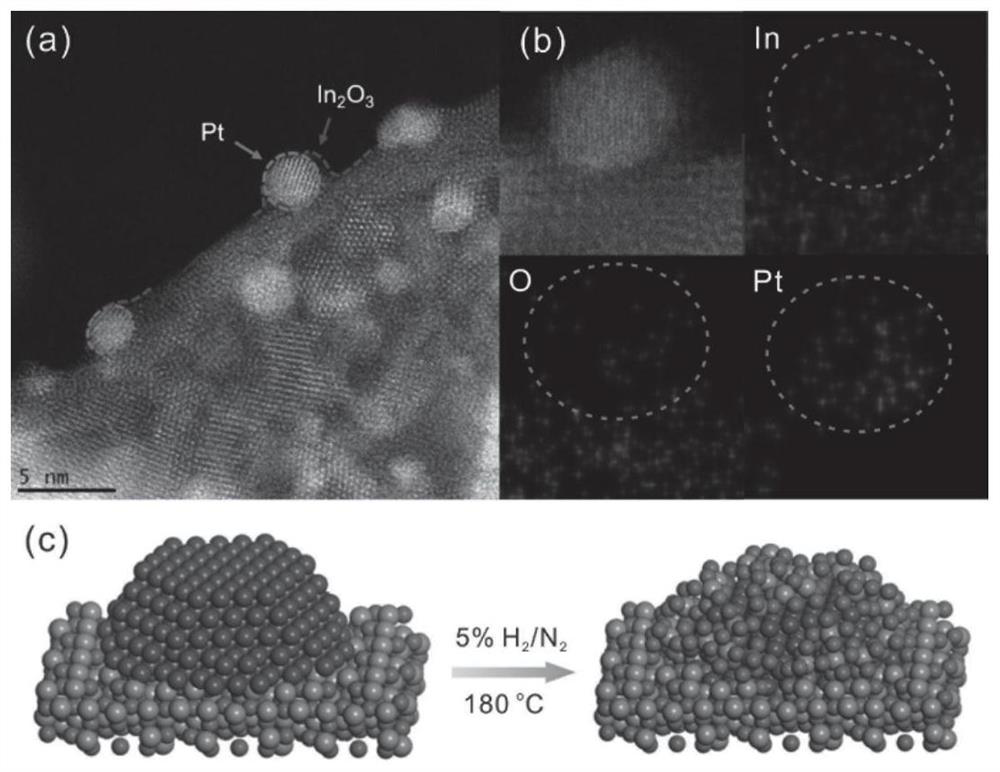

[0034] 3) Soak the first catalyst prepared in step 2) in indium nitrate aqueous solution or tin tetrachloride aqueous solution for 1-3 hours, centrifuge, vacuum-dry, and calcinate in a hydrogen atmosphere for 2-6 hours to obtain the catalyst containing Pt-In 2 o 3-x or Pt-SnO 2-x Supported catalysts with structural units.

[0035] figure 2 Contains Pt-In for the present invention 2 o 3-x The Raman test spectrum of the supported cataly...

Embodiment 1

[0044] 1-1 Preparation of Pt-In 2 o 3-x / Al 2 o 3 catalyst

[0045] 1) Weigh 1g Al 2 o 3 The solid powder was dispersed in deionized water, ultrasonically dispersed for 30 minutes, placed on a 400r / min magnetic stirrer, fully stirred evenly, and an aqueous solution dispersed with carriers was obtained;

[0046] 2) Weigh 200mg H 2 PtCl 6 Dissolve in 10mL of deionized water, drop by drop into the aqueous solution dispersed with the carrier, fully stir and impregnate overnight, centrifuge, wash with deionized water for 3 times, dry in vacuum, and calcinate at 180°C for 2-6h under hydrogen atmosphere , to prepare 1wt%Pt / Al 2 o 3 catalyst;

[0047] 3) 1wt%Pt / Al 2 o 3 The catalyst is soaked in 1mol / L indium nitrate aqueous solution for 1-3 hours, centrifuged, dried in vacuum, and calcined in a hydrogen atmosphere at 180°C for 2-6 hours to obtain 1wt% Pt-In 2 o 3-x / Al 2 o 3 Catalyst, wherein the molar ratio of Pt and In is (1:2).

[0048] 1-2 Catalytic hydrogenation...

Embodiment 2

[0051] Compared with Example 1, the difference is that the H weighed in step 1-1 2 PtCl 6 The mass is 100mg, and the Pt loading in the prepared catalyst is 0.5wt%, and other experimental conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com