GO-PSF composite film selection layer and preparation method and application thereof

A selective layer and composite membrane technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of reducing membrane flux and not using MBR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

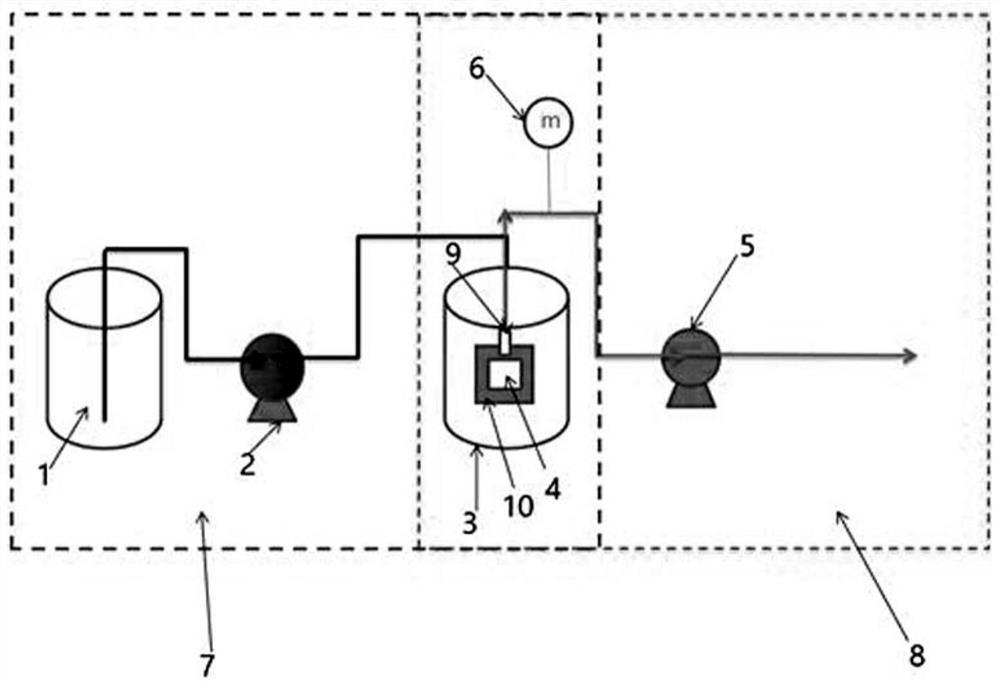

Image

Examples

Embodiment 1

[0032] Dry polysulfone in a vacuum oven at 80°C for 10 hours, mix polysulfone (10wt%), GO (0.025 wt%) and solvent dimethylacetamide into the Erlenmeyer flask, apply ultrasonic waves for 120min, and stir with magnetic force at room temperature Dissolve until the dissolved casting solution turns transparent gray, and let it stand for 10 hours. The commercial film (PSF) soaked in glycerol was taken out, and a film was formed on the PSF base film using a 50um and 100um scraper.

Embodiment 2

[0034] Carry out the anti-fouling experiment, and use the diaphragm pump to run for 4-5 hours, so that the membrane is quickly fouled, and the flux is reduced to 66.67% of the initial flux. Prepare 0.2% sodium hypochlorite solution, backwash for 2 minutes, and continue to test the water flux. The flux of the unmodified membrane rises to 77.83% of the initial flux; the flux of the 50um GO-PSF membrane rises to 50% of the initial flux. 88.83%, the flux of 100um GO-PSF membrane rose to the sum of 92.37% of the initial flux. It can be seen that through the preparation of GO-PSF composite membrane, the anti-fouling performance of the membrane is improved.

Embodiment 3

[0036] The dry commercial membrane (PSF) was taken out, and the GO-PSF casting solution was used to form a membrane on the PSF base membrane with a scraper, and the prepared membrane was installed in the pressure filtration experimental device, and the membrane flux was tested by water filtration under a pressure of 0.5 MPa. Compared with the basement membrane, it has decreased by 85.5%, indicating that the membrane pores are seriously blocked and are no longer suitable for MBR.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com