High-strength environment-friendly antibacterial wallpaper base paper and preparation method thereof

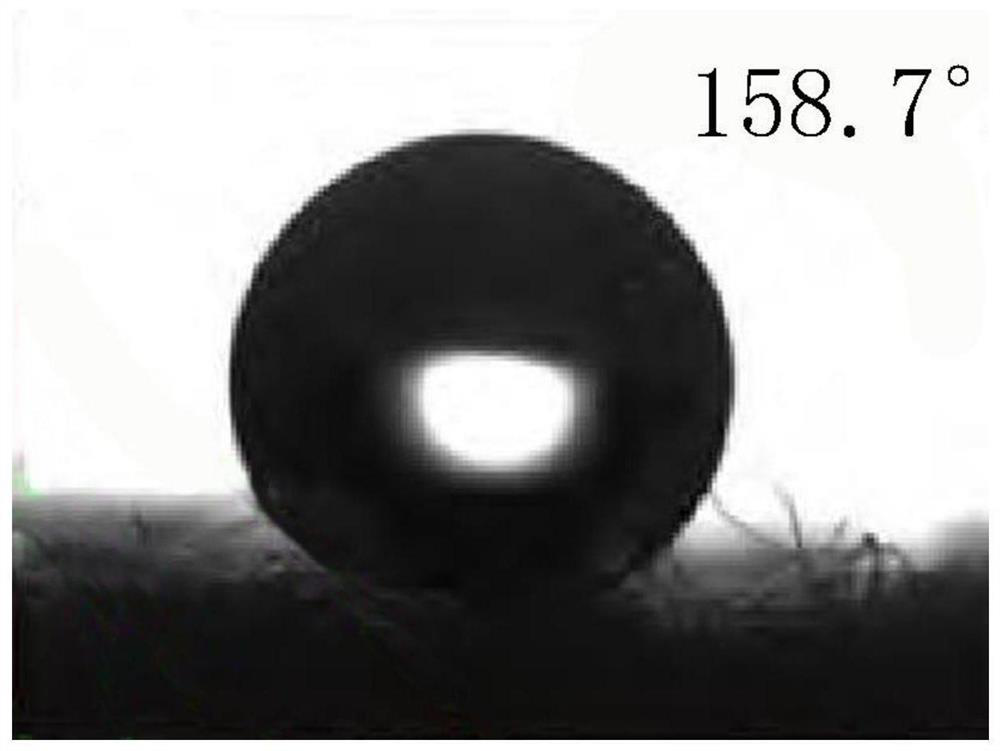

A high-strength, environmentally friendly technology, applied in pulp beating methods, special paper, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problem of usability and aesthetics decline, wallpaper water absorption curling and peeling, wallpaper use The scope is limited and other problems, to achieve the effect of significant hydrophobic effect, increase antibacterial ability, and increase hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

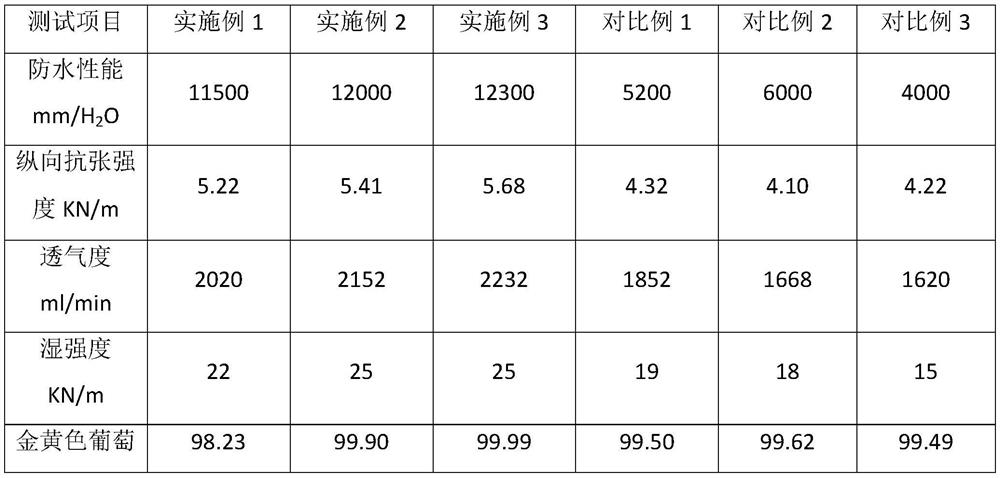

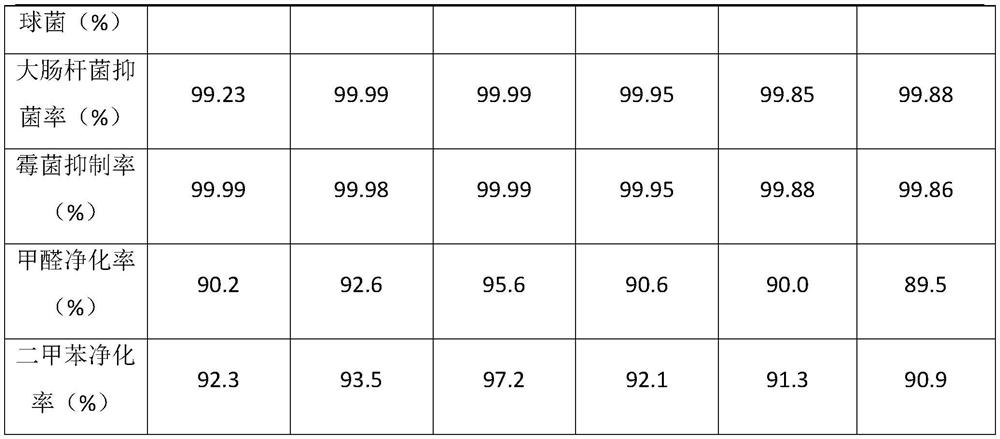

Embodiment 1

[0032] A high-strength environmental-friendly antibacterial wallpaper base paper is prepared from the following raw materials in parts by weight: 60 parts of wood pulp, 20 parts of modified chemical fiber, 20 parts of resin, 5 parts of gas adsorbent, 6 parts of wet strength agent, disperse 6 parts of agent, 1 part of antibacterial agent, and 1 part of synergist.

[0033] The wood pulp ratio is softwood pulp:hardwood pulp=15:90.

[0034] The modified chemical fibers are polyester fibers with a fineness of 1-5D and a length of 3-5mm.

[0035] The modified chemical fiber is prepared by the following method:

[0036] 1) Soak the chemical fibers in 20% ethanol solution for 1 hour, and the amount of ethanol solution is based on the total immersion of the chemical fibers;

[0037] 2) Add dopamine hydrochloride which is 1 / 4 of the mass of the chemical fiber and n-dodecanethiol which is 1 / 20 the mass of the chemical fiber to the mixture in step (1) and mix evenly, stir at 30°C for 12...

Embodiment 2

[0051] A high-strength environmental-friendly antibacterial wallpaper base paper is prepared from the following raw materials in parts by weight: 70 parts of wood pulp, 30 parts of modified chemical fiber, 25 parts of resin, 7 parts of gas adsorbent, 8 parts of wet strength agent, disperse 8 parts of agent, 2 parts of antibacterial agent, 3 parts of synergist.

[0052] The wood pulp ratio is softwood pulp:hardwood pulp=17:95.

[0053] The modified chemical fibers are polyester fibers with a fineness of 1-5D and a length of 3-5mm.

[0054] The modified chemical fiber is prepared by the following method:

[0055] 1) Soak the chemical fibers in 20% ethanol solution for 3 hours, and the amount of ethanol solution is based on the total immersion of the chemical fibers;

[0056] 2) Add dopamine hydrochloride which is 1 / 4 of the mass of the chemical fiber and n-dodecanethiol which is 1 / 20 the mass of the chemical fiber to the mixture in step (1) and mix evenly, stir at 30°C for 12 ...

Embodiment 3

[0069] A high-strength environmental-friendly antibacterial wallpaper base paper is prepared from the following raw materials in parts by weight: 80 parts of wood pulp, 40 parts of modified chemical fiber, 30 parts of resin, 10 parts of gas adsorbent, 10 parts of wet strength agent, disperse 10 parts of agent, 3 parts of antibacterial agent, 5 parts of synergist.

[0070] The wood pulp ratio is softwood pulp:hardwood pulp=20:100.

[0071] The modified chemical fibers are polyester fibers with a fineness of 1-5D and a length of 3-5mm.

[0072] The modified chemical fiber is prepared by the following method:

[0073] 1) Soak the chemical fibers in 20% ethanol solution for 3 hours, and the amount of ethanol solution is based on the total immersion of the chemical fibers;

[0074] 2) Add dopamine hydrochloride which is 1 / 4 of the mass of the chemical fiber and n-dodecanethiol which is 1 / 20 the mass of the chemical fiber to the mixture in step (1) and mix evenly, stir at 30°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com