Hydrophobic waterproof emulsion and preparation method thereof

A waterproof emulsion and hydrophobic technology, which is used in the addition of water repellents, textiles and papermaking, papermaking, etc. It can solve the problems that the water resistance effect cannot be maintained for a long time, the lotus leaf effect without hydrophobicity, and the system stability is poor, and achieves excellent hydrophobic effect. , high stability, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

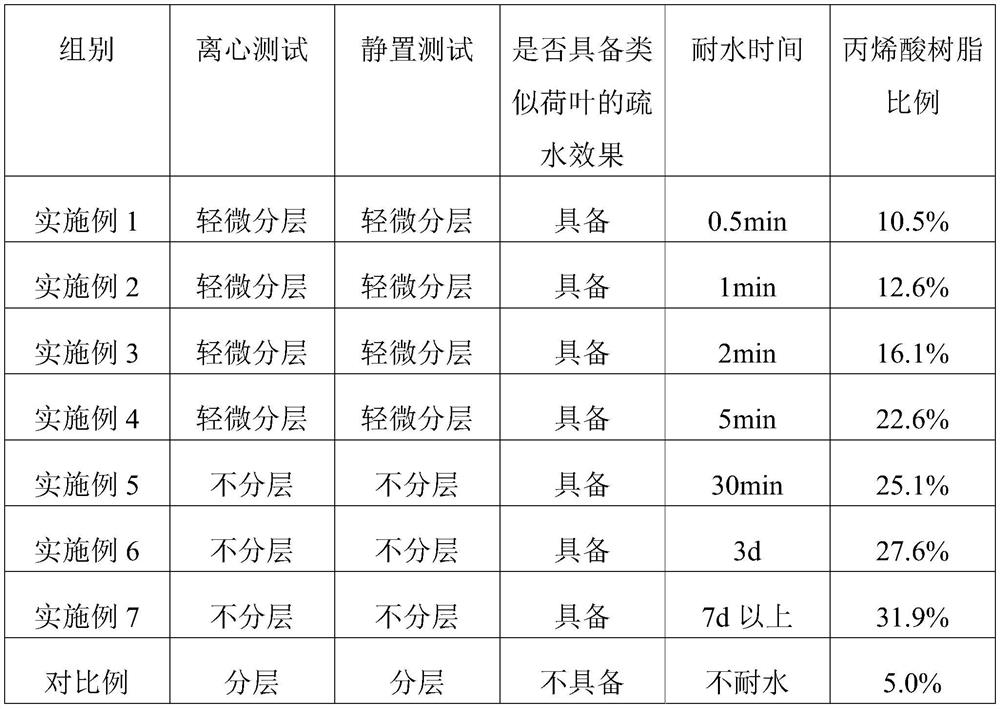

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing a hydrophobic and waterproof emulsion, comprising the following steps:

[0026] (1) 60kg water, 8kg emulsifier (BASF fatty alcohol polyoxyethylene ether sulfate sodium salt), 11kg natural wax, 10kg acrylic resin, 6kg palmitic acid (imported primary acid) are put into the emulsification kettle, heated and heated at 80r / The rotation speed of min is stirred to obtain the mixture a;

[0027] (2) Add 0.5 kg of defoamer (BYK024) to mixture a, start the homogenizer and emulsify for 2.5 hours at 80 r / min to obtain mixture b;

[0028] (3) Add 0.1kg preservative (OIT-45) to mixture b, and use DMEA and terpolymeric acid to adjust the pH of the emulsification system to 6, and obtain the hydrophobic and waterproof emulsion after discharging.

Embodiment 2

[0030] This embodiment provides a method for preparing a hydrophobic and waterproof emulsion, comprising the following steps:

[0031] (1) 58kg water, 8kg emulsifier (BASF fatty alcohol polyoxyethylene ether sulfate sodium salt), 10kg natural wax, 12kg acrylic resin, 6kg palmitic acid (imported primary acid) are put into the emulsification kettle, heated and heated at 100r / The rotation speed of min is stirred to obtain the mixture a;

[0032] (2) Add 0.8 kg of defoamer (BYK024) to mixture a, start the homogenizer and emulsify for 2 hours at 100 r / min to obtain mixture b;

[0033] (3) Add 0.15kg of preservative (OIT-45) to the mixture b, and adjust the pH of the emulsification system to 6.5 with DMEA and terpolymeric acid, and obtain the hydrophobic and waterproof emulsion after discharging.

Embodiment 3

[0035] This embodiment provides a method for preparing a hydrophobic and waterproof emulsion, comprising the following steps:

[0036] (1) 55kg water, 8kg emulsifier (BASF fatty alcohol polyoxyethylene ether sulfate sodium salt), 9kg natural wax, 15kg acrylic resin, 5kg palmitic acid (imported primary acid) are put into the emulsification kettle, heated and heated at 90r / The rotation speed of min is stirred to obtain the mixture a;

[0037] (2) Add 1 kg of defoamer (BYK024) to mixture a, start the homogenizer and emulsify for 2 hours at 90 r / min to obtain mixture b;

[0038] (3) Add 0.2 kg of preservative (OIT-45) to the mixture b, and adjust the pH of the emulsification system to 7 with DMEA and terpolymeric acid, and obtain the hydrophobic and waterproof emulsion after discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com