Method for determining steel ball ratio based on grinding kinetics

A technology of dynamics and dynamic parameters, applied in complex mathematical operations, grain processing, etc., can solve problems such as the application of grinding dynamics, theoretical research on dynamic parameters of residence, etc., to achieve a scientific and reasonable steel ball ratio and a practical method , the effect of increasing the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The method for determining the ratio of steel balls based on grinding kinetics, the specific operations are as follows:

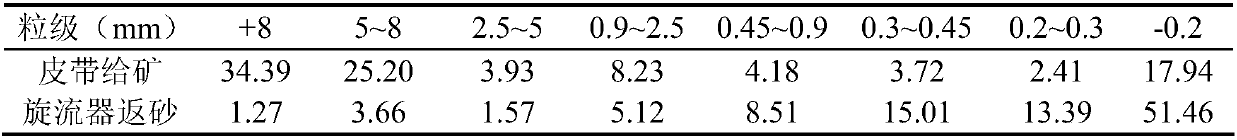

[0022] (1) According to the test requirements, samples were taken from the belt feeding of the ball mill of Jiangxi Yongping Copper Mine Concentrator and the sand returning from the cyclone. The belt feeding samples were taken once an hour, and a total of 24 times were taken, and the samples were mixed. , the total amount is 100kg, and the sample of sand returned from the cyclone is taken once an hour, and a total of 24 times are taken, and the samples are mixed evenly, and the total amount is 100kg; Cover sieve and laser particle size analyzer carry out particle size analysis, and its result is as shown in table 1;

[0023] Table 1 Particle size sieve analysis result composition %

[0024]

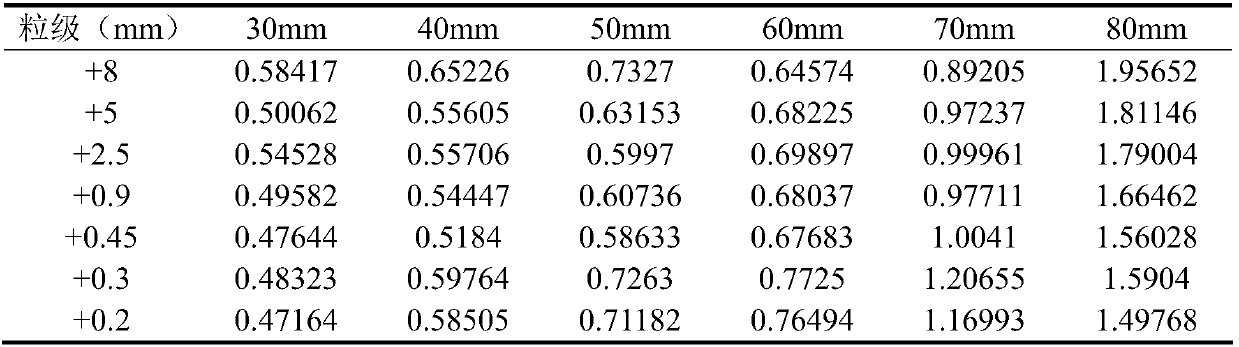

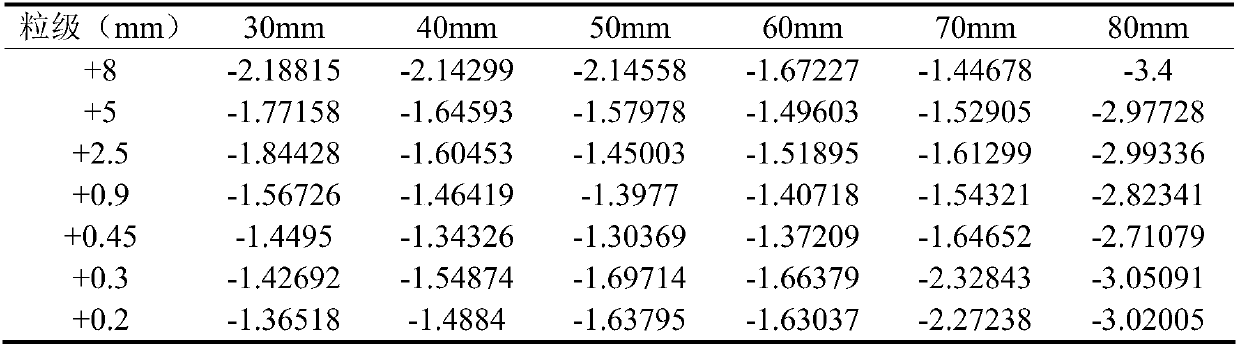

[0025] (2) The grinding particle size is +0.2mm, so the products of each size above +0.2mm are blended according to the sand return ratio of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com