A low vanadium hydrogen storage alloy and its preparation method and use

A technology for hydrogen storage alloys and uses, applied in chemical instruments and methods, hydrogen, non-metallic elements, etc., can solve the problem of low hydrogen absorption and desorption of hydrogen storage alloys, low hydrogen release platform pressure of hydrogen storage alloys, and large platform slopes. and other problems, to achieve the effect of fast hydrogen absorption and desorption rate, increased hydrogen absorption and desorption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

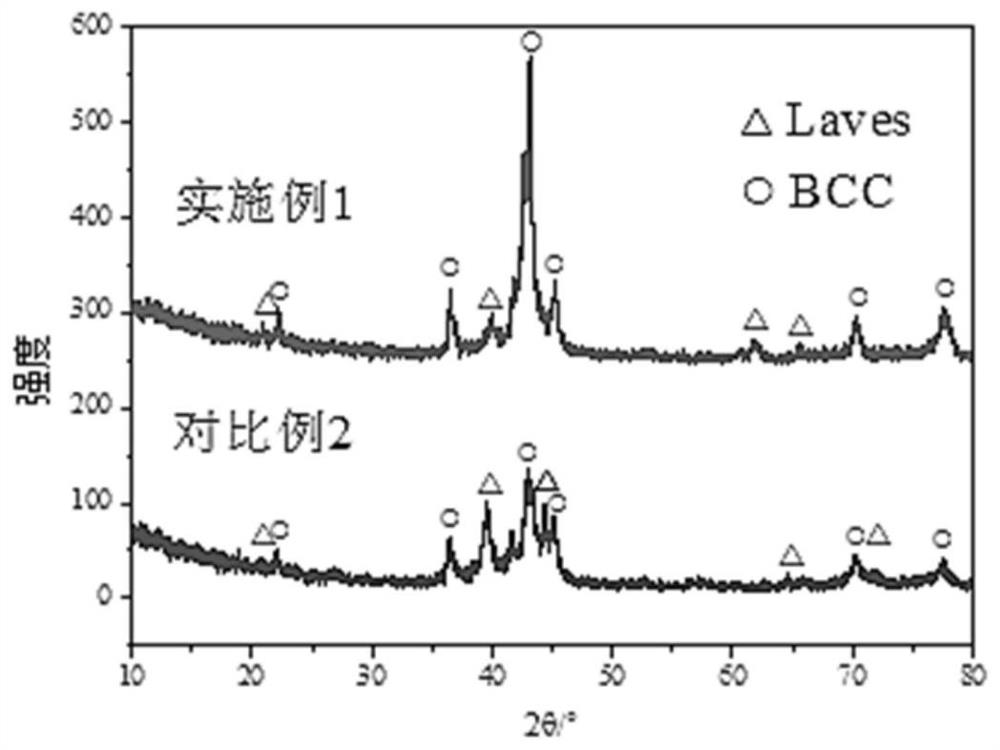

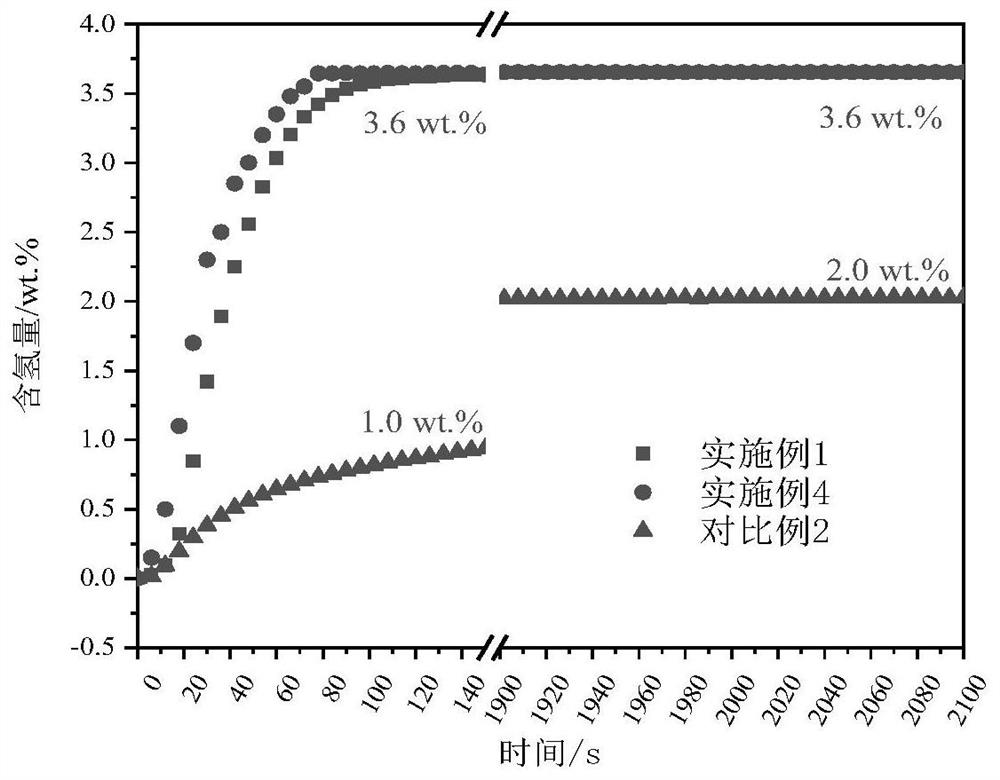

[0053] This embodiment provides a low vanadium hydrogen storage alloy, the element ratio of the low vanadium hydrogen storage alloy is: (TiV 0.1 ) 0.45 (CrMo 0.1 ) 0.55 ;

[0054] Prepared as follows:

[0055] (1) According to the formula, the metal powder is used for batching, and then smelted to obtain the intermediate material;

[0056] (2) The intermediate material obtained in step (1) is subjected to vacuum suction casting and heat treatment in sequence to obtain the hydrogen storage alloy.

[0057] The electric current in the smelting is 150A, and the time of smelting is 15s, carried out 5 times;

[0058] The current in the vacuum suction casting is 100A, and the time is 20s;

[0059] Vacuumizing is carried out during the heat treatment, and the vacuuming is to maintain a vacuum degree≤0.0001Pa;

[0060] The temperature of the heat treatment is 500° C. and the time is 1 h.

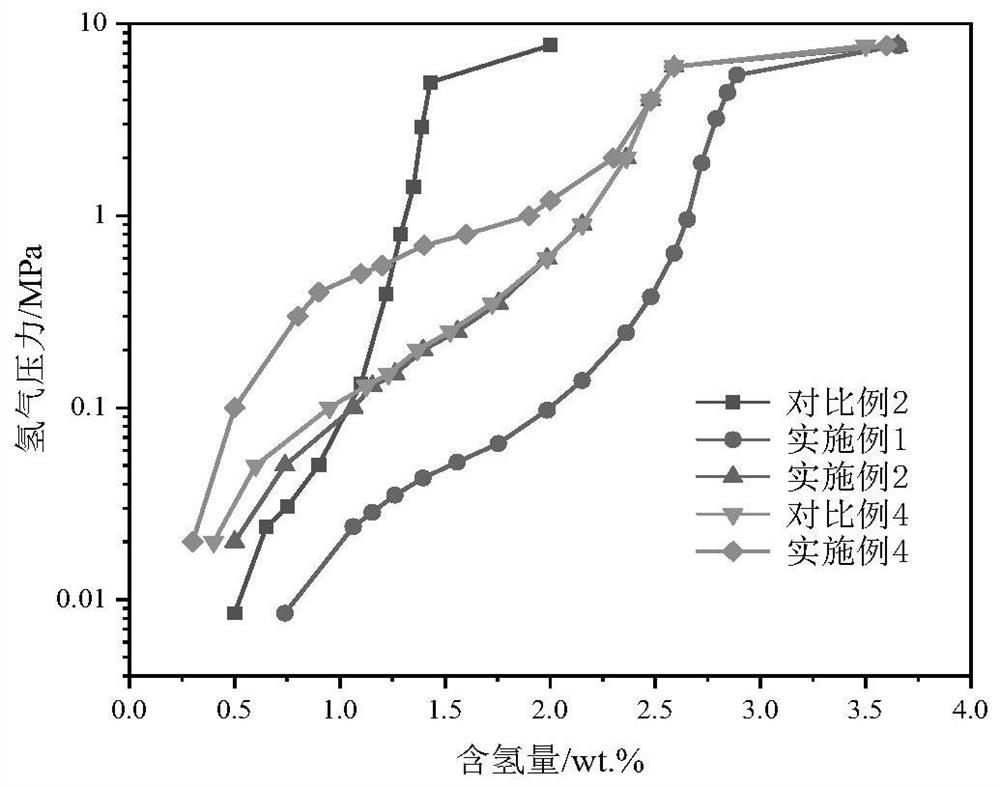

[0061] The properties of the gained hydrogen storage alloy are shown in Table 1, and the ...

Embodiment 2

[0063] This embodiment provides a low vanadium hydrogen storage alloy, the element ratio of the low vanadium hydrogen storage alloy is: (TiV 0.15 ) 0.4 (CrMo 0.15 ) 0.6 ;

[0064] Prepared as follows:

[0065] (1) batching according to the formula, and then smelting to obtain the intermediate material;

[0066] (2) The intermediate material obtained in step (1) is subjected to vacuum suction casting and heat treatment in sequence to obtain the hydrogen storage alloy.

[0067] The current in the smelting is 100A, and the smelting time is 10s, which is carried out 3 times;

[0068] The current in the vacuum suction casting is 200A, and the time is 15s;

[0069] Vacuumizing is carried out during the heat treatment, and the vacuuming is to maintain a vacuum degree≤0.00004Pa;

[0070] The temperature of the heat treatment is 400°C and the time is 1.5h.

[0071] The properties of the obtained hydrogen storage alloy are shown in Table 1, and the hydrogen desorption PCT curve ...

Embodiment 3

[0073] This embodiment provides a low vanadium hydrogen storage alloy, the element ratio of the low vanadium hydrogen storage alloy is: (TiV 0.1 ) 0.5 (CrMo 0.05 ) 0.5 ;

[0074] Prepared as follows:

[0075] (1) batching according to the formula, and then smelting to obtain the intermediate material;

[0076] (2) The intermediate material obtained in step (1) is subjected to vacuum suction casting and heat treatment in sequence to obtain the hydrogen storage alloy.

[0077] The current in the smelting is 200A, and the smelting time is 15s, which is carried out 4 times;

[0078] The current in the vacuum suction casting is 150A, and the time is 10s;

[0079] Vacuumizing is carried out during the heat treatment, and the vacuuming is to maintain a vacuum degree≤0.00008Pa;

[0080] The temperature of the heat treatment is 600°C and the time is 1.3h.

[0081] The properties of the obtained hydrogen storage alloys are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com