Tissue adhesive as well as preparation method and application thereof

A tissue adhesive and cross-linking agent technology, used in applications, surgical adhesives, pharmaceutical formulations, etc., can solve the problems that cannot fully meet clinical needs, poor mechanical properties, and lack of cell affinity and tissue affinity for super-strong hydrogels. Adhesion and other issues, to achieve the effect of good wide applicability, good biocompatibility, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 2 g of gelatin (bovine source) was dissolved in 20 mL of deionized water at 60° C. to obtain a 10 wt / vol % gelatin solution. After adjusting the pH value to 8.5 with sodium hydroxide solution, use a syringe to drop 0.2 g / mL tannic acid aqueous solution into the gelatin solution (a total of 1 mL of tannic acid aqueous solution is used), and wait until it is completely dissolved and mixed evenly ( The time was controlled at 0.5 h), and the pH of the solution was adjusted to 7.1 with hydrochloric acid solution, which was recorded as solution I.

[0064] Dissolve 0.04 g of genipin in 1 mL of 70% ethanol solution at room temperature. Subsequently, solution I and genipin solution (volume ratio 1:1) were poured into a double-syringe syringe, extruded, at room temperature (25°C), in situ cross-linking reaction, reacted for 10 minutes, and obtained a Strong tissue adhesive.

[0065] Use a double-syringe syringe to extrude solution I and genipin solution (volume ratio 1:1) onto...

Embodiment 2

[0069] 1.5 g of gelatin (from fish) was dissolved in 20 mL of deionized water at 40° C. to obtain a 7.5 wt / vol % gelatin solution. After adjusting the pH value to 8.1 with sodium hydroxide solution, use a syringe to add 0.5 g / mL gallic acid aqueous solution dropwise into the gelatin solution (a total of 1 mL of gallic acid aqueous solution is used), and wait until it is completely dissolved and mixed evenly (time control At 0.75 h), the pH of the solution was adjusted to 7.1 with hydrochloric acid solution, which was designated as solution I.

[0070] Dissolve 0.08 g of genipin in 2 mL of 75% ethanol solution at room temperature. Subsequently, solution I and genipin solution (volume ratio: 3:1) were poured into a double-syringe syringe, extruded, at room temperature (20°C), in situ cross-linking reaction, reacted for 15 minutes, and obtained a high-strength adhesive Strong tissue adhesive.

[0071] Extrude solution I and genipin solution (volume ratio: 3:1) using a double-sy...

Embodiment 3

[0075] 1.5 g of gelatin (porcine origin) was dissolved in 30 mL of deionized water at 40° C. to obtain a 5 wt / vol % gelatin solution. After adjusting the pH value to 8.8 with sodium hydroxide solution, use a syringe to add 0.8 g / mL tannic acid aqueous solution dropwise to the gelatin solution (a total of 1 mL of tannic acid aqueous solution is used), and adjust the pH of the solution to 7.1 with hydrochloric acid solution , denoted as solution I.

[0076] Dissolve 0.1 g of genipin in 1 mL of 75% ethanol solution at room temperature. Subsequently, solution I and genipin solution (volume ratio 1.5:1) were poured into a double-syringe syringe, extruded, at room temperature (30°C), in situ cross-linking reaction, reacted for 20 minutes, and obtained a strong adhesive Strong tissue adhesive.

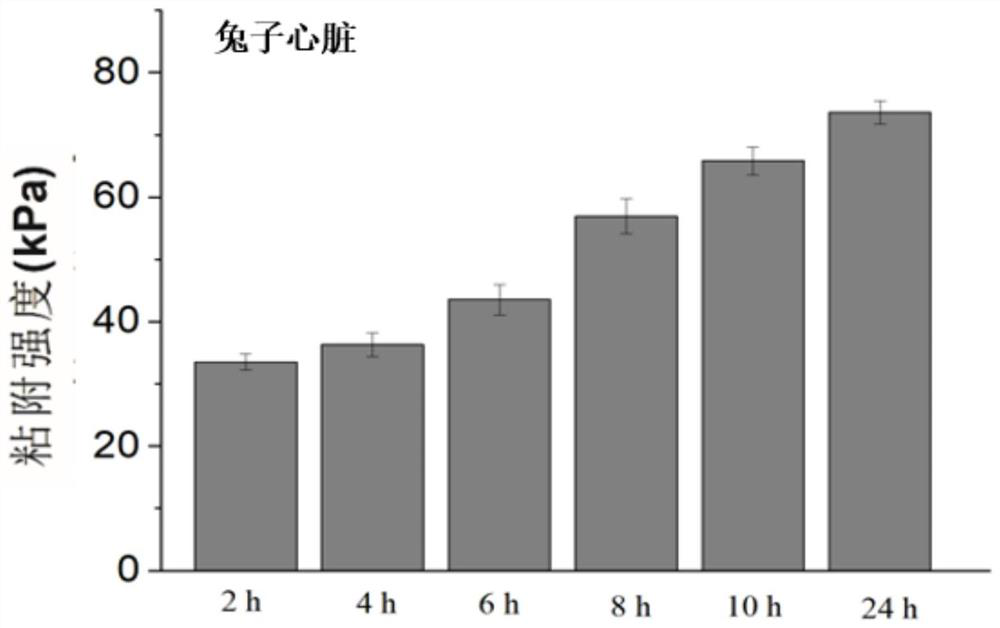

[0077] Extrude solution I and genipin solution (volume ratio: 1.5:1) with a double-syringe syringe onto the surface of pigskin, rabbit heart, aminated glass, etc. At the lap joint for 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com