Transparent PI hardened coating resistant to ultraviolet damp-heat aging and preparation method of transparent PI hardened coating

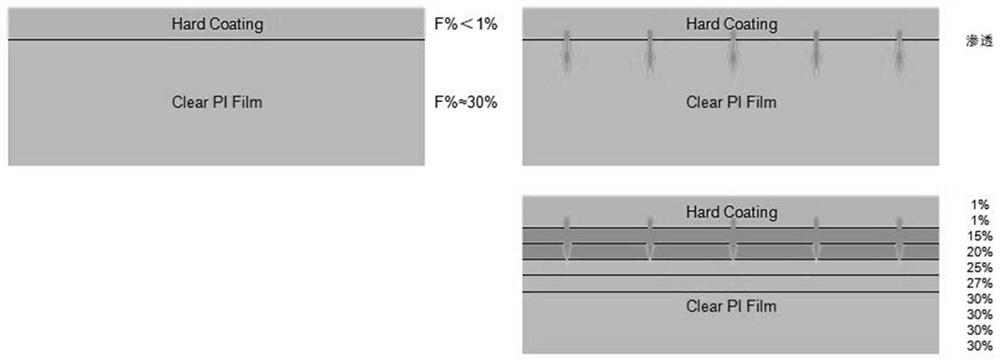

A technology of hard coating and damp heat aging, applied in coatings, polyester coatings, polyether coatings, etc., can solve the problems of difficult adhesion of hard coatings, peeling of hard coatings, damage to screen creases, etc., and achieve industrialization. , increase the cost, ensure the effect of hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail now in conjunction with embodiment.

[0031] The preparation method of the hardening liquid used for preparing the transparent PI hardened coating is as follows: weighing each component in proportion and mixing them evenly.

[0032] A preparation method for a transparent PI hardened coating resistant to ultraviolet, humidity and heat aging, comprising the steps of:

[0033] (1) Use dimple coating equipment to evenly coat the hardening solution on the transparent PI substrate, and then perform thermal drying and thermal curing;

[0034] (2) Carry out UV curing, after cooling, stick the protective film and cut it.

[0035] Drying conditions:

[0036] Condition 1: The distance from the coating head to the drying tunnel is 2.5 meters (the travel time from the coating head to the drying tunnel is 0.5-1min, the temperature is 20-30°C), there are 16 drying tunnels, each section is 2.5 meters, and the speed is 2.5 meters pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com