Glass protecting ink and preparation method thereof

A technology for protecting ink and glass, used in ink, home appliances, applications, etc., can solve the problems of scratched glass, mild or severe glass scratches, manual peeling, etc., to enhance adhesion, reduce shrinkage, improve The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the synthesis of epoxy acrylic resin

[0036] Take 424g of epoxy resin (epoxy equivalent of 212), 130g of acrylic acid, 0.65g of hydroquinone, and 0.6g of benzylamine, add them into a three-necked flask, heat to 100°C, and react for 3 hours to obtain an acid value of less than 5mg(KOH) / The composition of g; at this time, cool down to 80°C, add 202g of phthalic anhydride, heat to 100°C after the phthalic anhydride dissolves, and react for 4 hours to obtain an epoxy acrylic resin with an acid value of 80-120mg (KOH) / g. Its chemical structural formula is as follows:

[0037]

[0038] Among them, R 2 for n≈4.5.

Embodiment 2

[0039] Embodiment 2: the synthesis of polyurethane acrylic resin

[0040] Take isophorone diisocyanate (IPDI) 300g, hydroxyethyl methacrylate (HEMA) 244.4g, hydroquinone 0.5g, dibutyltin oxide 0.1g, heat to 60°C for 3 hours, then add polyethylene Diol (PEG 300 ) of 284 g, continue to heat to 70° C. for 4 hours, and monitor the content of -NCO by infrared spectroscopy until the reaction of -NCO is complete to obtain the polyurethane acrylic resin. Its chemical structural formula is as follows:

[0041]

Embodiment 3

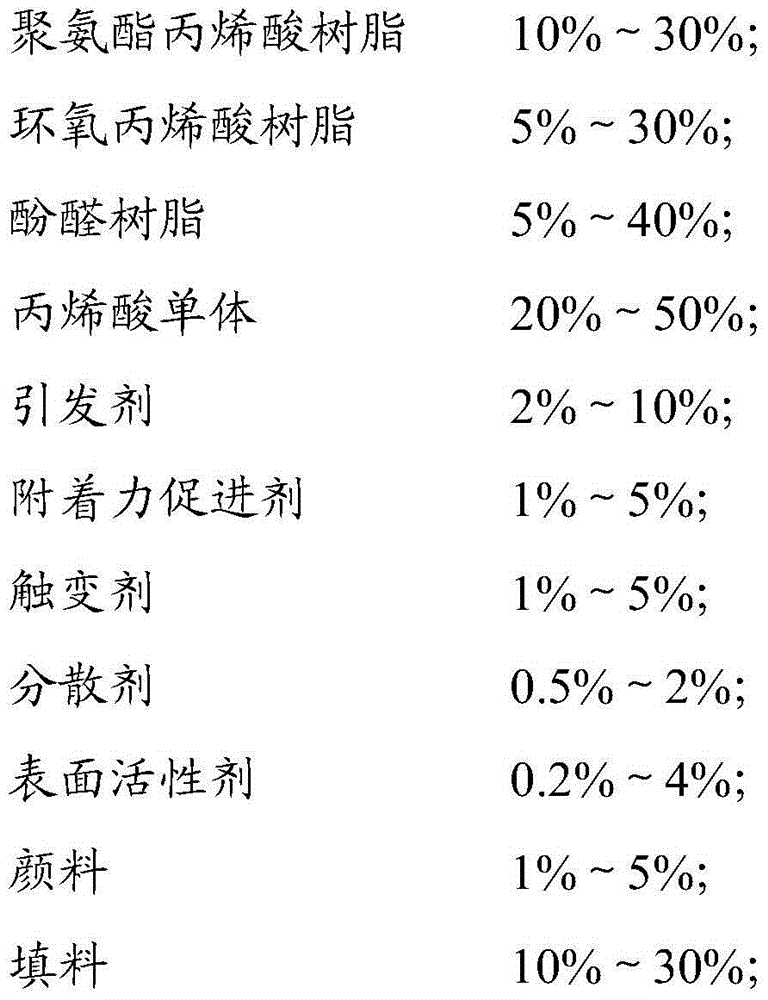

[0042] Embodiment 3: Preparation of UV-curable glass protection ink

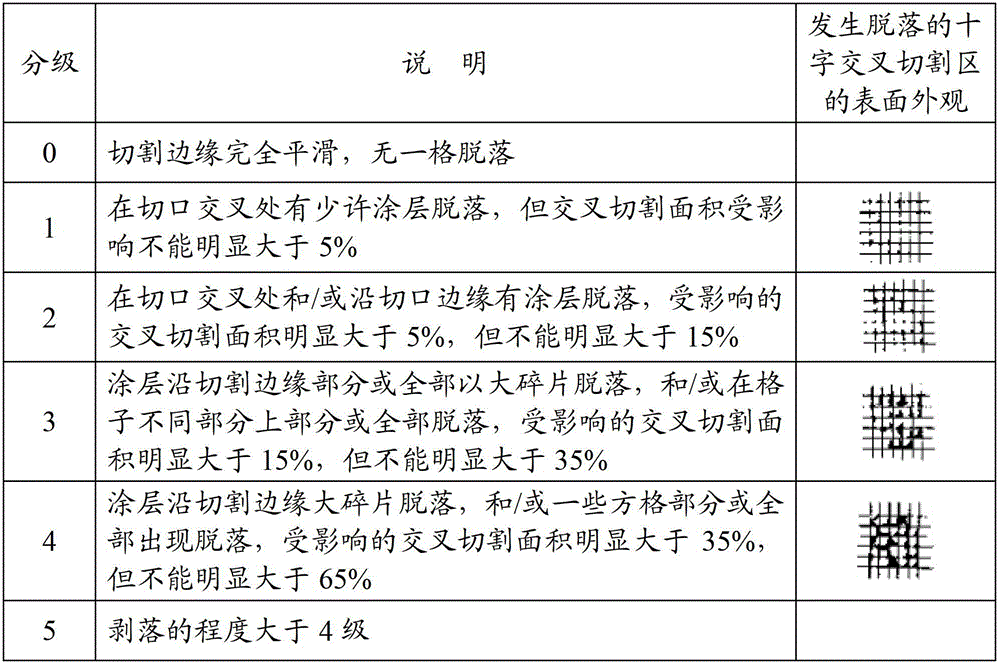

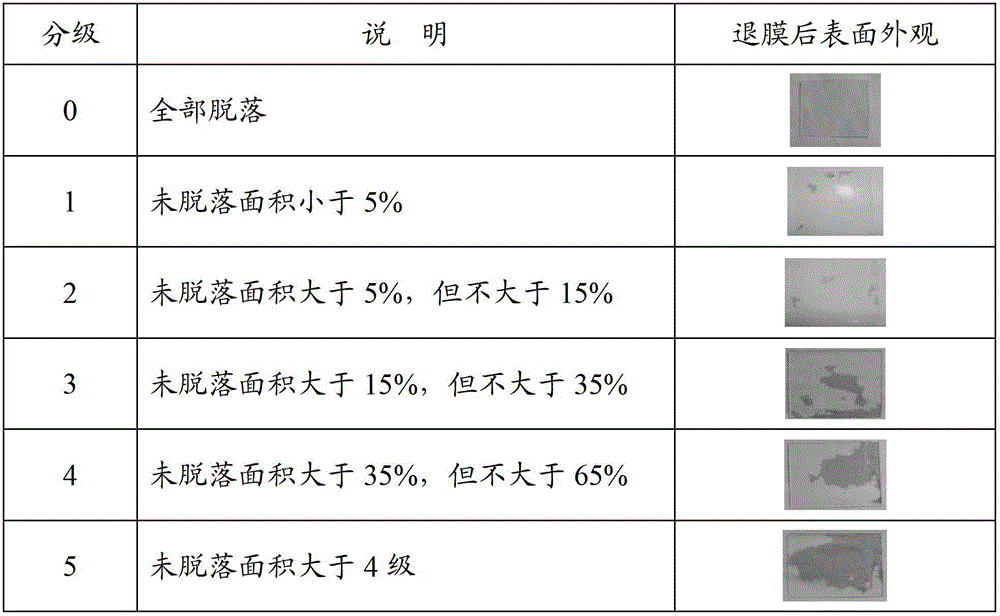

[0043] Weigh each component according to the following weight percentage, disperse and mix each component and then grind to prepare the UV curing glass protection ink:

[0044]

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com