A kind of preparation method of anti-mildew polyurethane prepolymer

A polyurethane prepolymer and anti-mildew technology, applied in the field of polyurethane, can solve the problems of poor storage stability, waste and loss of raw materials, and achieve good anti-mildew performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

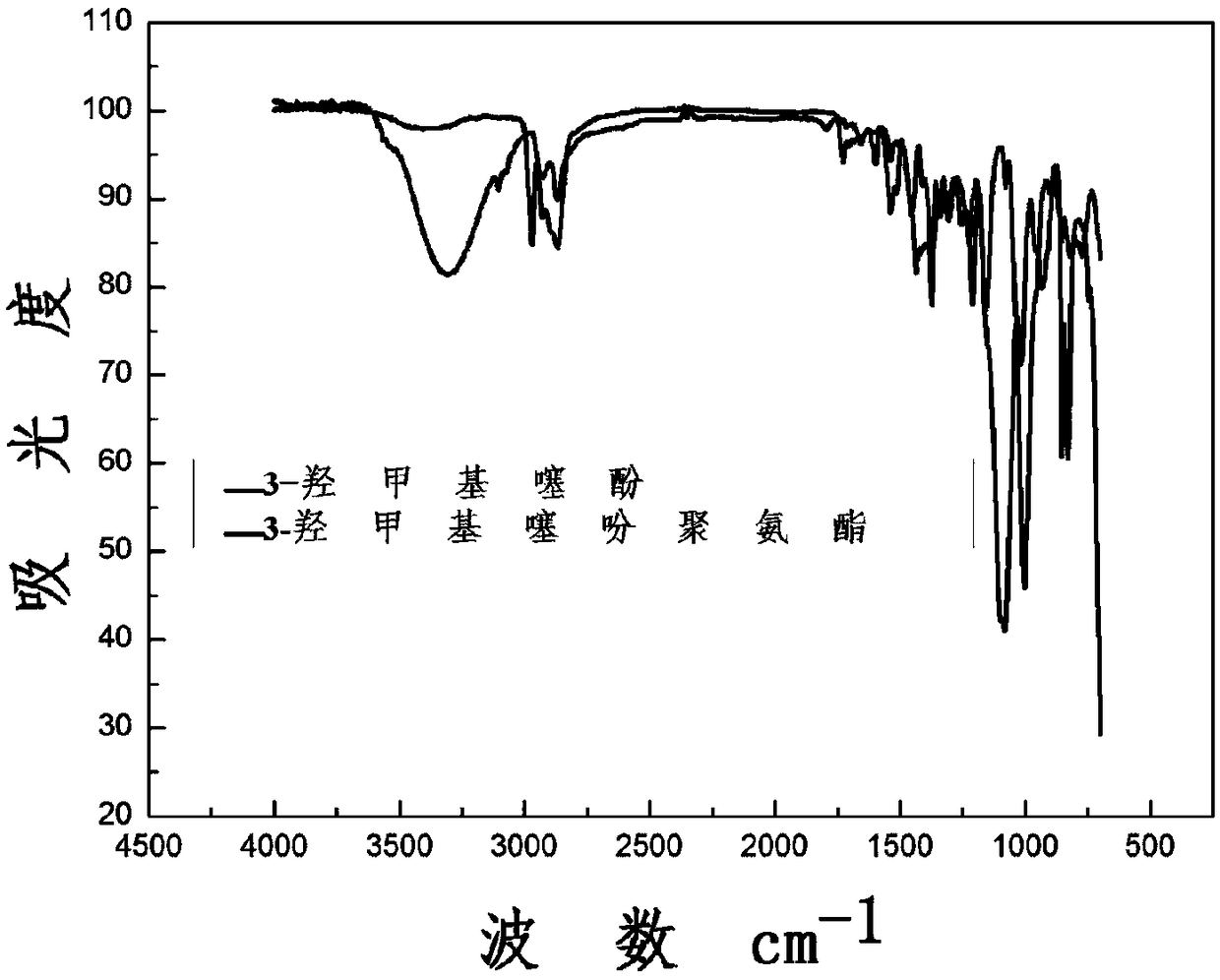

Image

Examples

Embodiment 1

[0035] A kind of preparation method of anti-mildew polyurethane prepolymer, comprises the steps:

[0036] 1) In terms of parts by mass, add 60 parts of polyether diol (PPG-8000) with a relative molecular weight of 8000 and 20 parts of polyether triol (PPG-5000) with a relative molecular weight of 5000 into the reaction kettle , vacuumize, control the temperature at 120°C, and stir for 2 hours;

[0037] 2) In terms of parts by mass, under the protection of nitrogen, the system was cooled to 42°C, 30 parts of diphenylmethane diisocyanate (MDI) was added to the reaction kettle, 0.1 part of dibutyltin dilaurate was added, and The maximum stirring speed is 300rpm / min, and the temperature is controlled at 80°C for 3 hours;

[0038] 3) In terms of parts by mass, add 0.13 parts of silane coupling agent KH-550 to the reaction system, continue to stir, and react for 2 hours;

[0039] 4) In terms of parts by mass, add 0.01 part of 3-hydroxymethylthiophene to the system, continue stirri...

Embodiment 2

[0045] A kind of preparation method of anti-mildew polyurethane prepolymer, comprises the steps:

[0046] 1) In terms of parts by mass, add 60 parts of polyether diol (PPG-1000) with a relative molecular weight of 1000 and 20 parts of polyether triol (PPG-3000) with a relative molecular weight of 3000 into the reaction kettle , vacuumize, control the temperature at 120°C, and stir for 2.5 hours;

[0047] 2) In terms of parts by mass, under the protection of nitrogen, the temperature of the system was lowered to 40°C, 30 parts of diphenylmethane diisocyanate (MDI) was added to the reaction kettle, 0.1 part of dibutyltin dilaurate was added, and The maximum stirring speed is 300rpm / min, and the temperature is controlled at 80°C for 3 hours;

[0048]3) In terms of parts by mass, add 0.12 parts of silane coupling agent KH-550 to the reaction system, continue to stir, and react for 2 hours;

[0049] 4) In terms of parts by mass, add 0.5 parts of 3-hydroxymethyl-trithiophene to th...

Embodiment 3

[0053] A kind of preparation method of anti-mildew polyurethane prepolymer, comprises the steps:

[0054] 1) In terms of parts by mass, add 54 parts of polyether diol (PPG-4000) with a relative molecular weight of 4000 and 30 parts of polyether triol (PPG-5000) with a relative molecular weight of 5000 into the reactor, Vacuumize, control the temperature at 120°C, and stir for 2 hours;

[0055] 2) In terms of parts by mass, under the protection of nitrogen gas, the system was cooled to 45°C, 36 parts of isophorone diisocyanate (IPDI) was added to the reaction kettle, 0.2 parts of dibutyltin dilaurate was added, and The maximum stirring speed is 300rpm / min, and the temperature is controlled at 75°C for 3.5 hours;

[0056] 3) In terms of parts by mass, the amount of silane coupling agent KH-170 added to the reaction system is 0.26 g, and the stirring is continued for 3 hours;

[0057] 4) In terms of parts by mass, add 1 part of 3-hydroxythiophene to the system, continue to stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com