Industrial sewage filtering treatment dischargeable equipment

A technology for industrial sewage and equipment, applied in filtration treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as unsuitable for a large amount of sewage filtration, single function, etc., to prevent sewage overflow, improve Purity, Pollution Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A dischargeable equipment for industrial sewage filtration treatment, such as figure 1 As shown, it includes a base 1 , a water storage mechanism 2 and a filter mechanism 3 , the water storage mechanism 2 is connected to the left side of the base 1 , and the filter mechanism 3 is connected between the base 1 and the water storage mechanism 2 .

[0068] When people need to filter industrial sewage, they first connect the downpipe to the parts of the water storage mechanism 2, and the sewage flows into the filter mechanism 3 through the water storage mechanism 2 for filtering, and finally discharges.

Embodiment 2

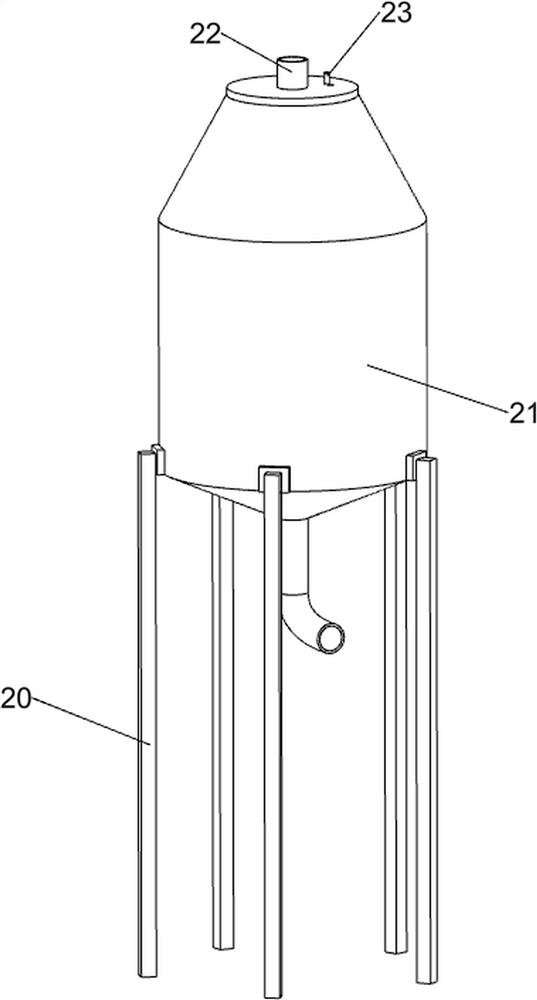

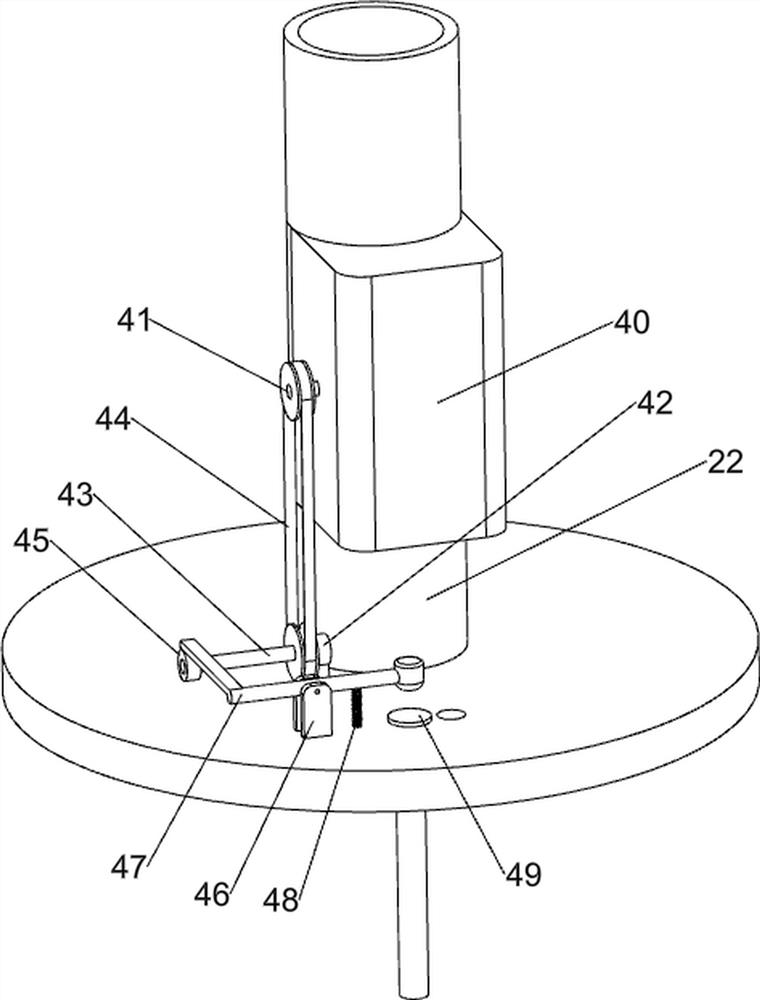

[0070] On the basis of Example 1, such as Figure 2-5As shown, the water storage mechanism 2 includes a first pillar 20, a water storage tank 21, a first water pipe 22 and a water level gauge 23. The left side of the base 1 is evenly connected with the first pillar 20, and the upper part of the first pillar 20 is connected with a storage tank. The water tank 21 is connected with the first water pipe 22 on the top of the water storage tank 21, and the water level gauge 23 is provided on the rear side of the water storage tank 21.

[0071] When people need to filter industrial sewage, first connect the downpipe to the first water pipe 22, so that the sewage flows into the water storage tank 21, then flows into the filtering mechanism 3 for filtering, and finally discharges.

[0072] The filter mechanism 3 includes a second pillar 30, a filter tank 31 and a second water pipe 32, two second pillars 30 are connected in the middle of the base 1, and a filter tank 31 is connected bet...

Embodiment 3

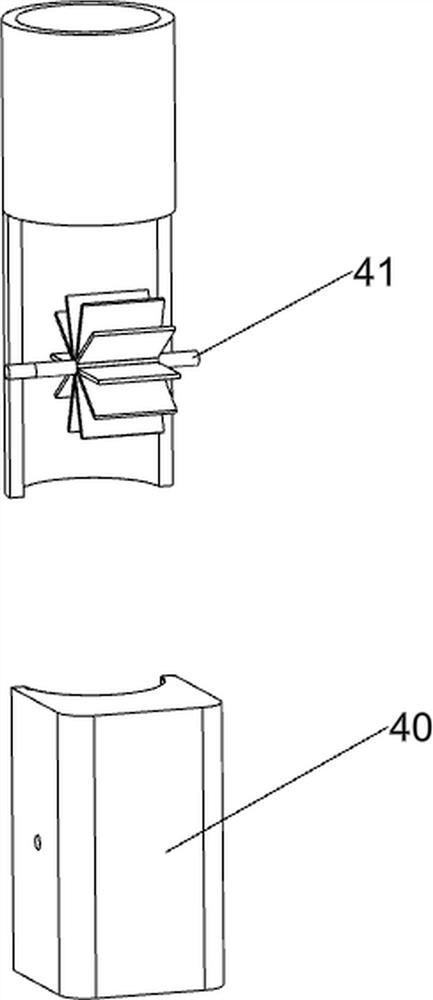

[0077] On the basis of Example 2, such as Figure 6-11 As shown, a supercharging mechanism 5 is also included, and the supercharging mechanism 5 includes a third pillar 50, a fourth bearing seat 51, a third rotating shaft 52, a water storage tank 53, a fourth rotating shaft 54, a second belt drive assembly 55, an outlet The air pipe 56 and the third water pipe 57, two third pillars 50 are connected to the right rear side of the base 1, and a water storage tank 53 is arranged between the tops of the third pillars 50, and the water storage tank 53 is connected to the filter tank 31, and the rear side of the second water pipe 32 A fourth bearing seat 51 is provided, the fourth bearing seat 51 is rotatably connected with a third rotating shaft 52, the third rotating shaft 52 is connected with a second fan blade, and the middle of the water storage tank 53 is rotatably connected with a fourth rotating shaft 54. The four rotating shafts 54 are connected with a third fan blade, a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com