Durable steel belt material cooling conveyor

A technology for cooling conveyors and steel belts, applied in conveyors, household refrigeration devices, applications, etc., can solve the problems of affecting water spraying operations, easy damage and deformation of steel belts, and heavy daily maintenance workload, etc., to achieve daily maintenance The effect of small workload, overcoming the easy wear of the steel belt, and low daily use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

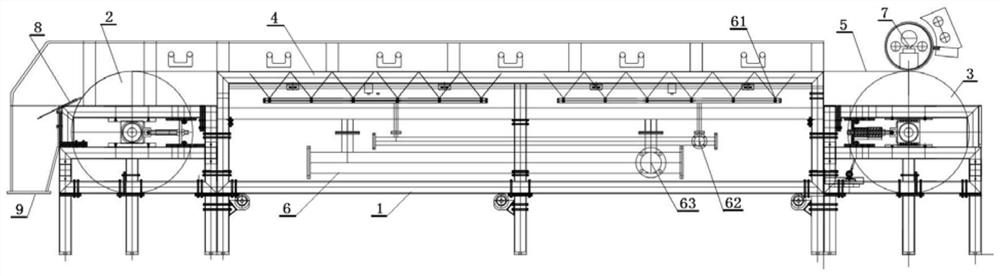

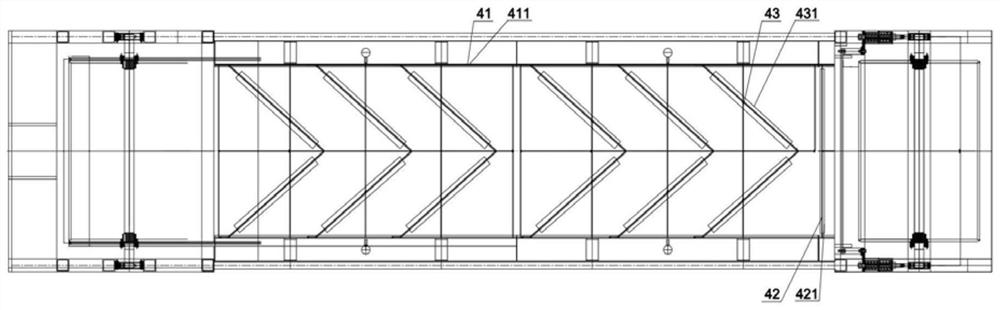

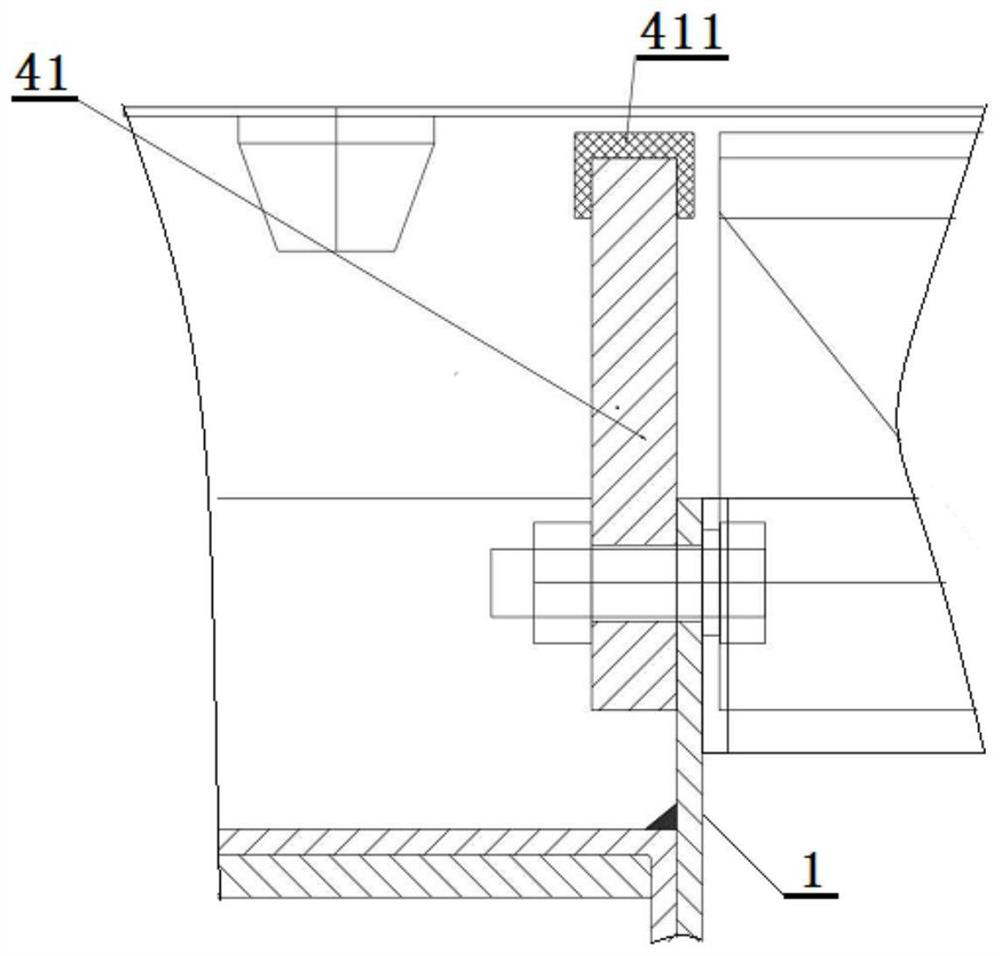

[0021] exist figure 1 , figure 2 with image 3 In the durable steel belt material cooling conveyor of the present invention, the main body includes a frame 1, and the main driving drum 2 and the driven tensioning drum 3 are respectively arranged on the front and rear sides of the frame. Steel belt bearing platform 4 composed of longitudinal support plates 41 on the left and right frames of the frame, transverse support plates 42 respectively arranged on the front and rear frames of the frame, and several V-shaped support plates 43 arranged at intervals between the left and right frames of the frame , the closed-loop steel belt 5 is arranged between the main driving drum 2 and the driven tensioning drum 3, and is arranged under the steel belt carrying platform 4, and is provided with a cooling water inlet 62, a cooling water outlet 63 and seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com