Heat-removing constant-temperature structure for high-power LED lamp

A technology of LED lamps and LED lamp beads, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc. Death and other problems, to achieve the effect of short structure, ensuring work efficiency and life, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

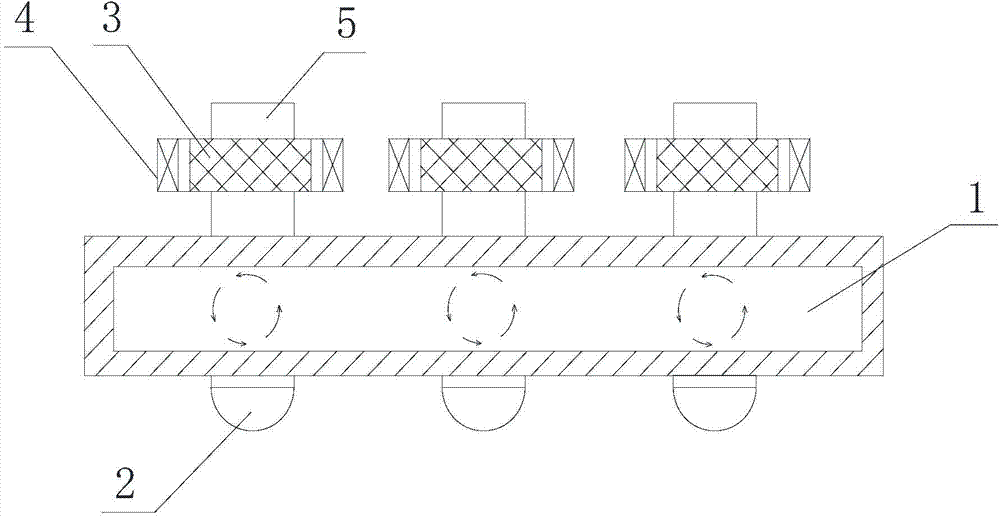

[0029] like figure 1 As shown, a heat removal and constant temperature structure of a high-power LED lamp includes: a flat gas-liquid conversion hollow cavity 1 , LED lamp beads 2 , a magnetic working medium 3 and an excitation device 4 .

[0030] Wherein, the LED lamp bead 2 is installed on one side of the gas-liquid conversion hollow cavity 1, and a hollow round tube 5 corresponding to the LED lamp bead 2 is arranged on the other side of the gas-liquid conversion hollow cavity 1, and the hollow round tube 5 is The outer protrusion, the diameter of the hollow tube 5 is consistent with the size of the substrate of the LED lamp bead 2 . The magnetic working medium 3 is arranged on the outer wall of the hollow tube 3 , and the excitation device 4 corresponds to the magnetic working medium 3 and is used to excite and demagnetize the magnetic working medium 3 .

[0031] In actual work, if the high-power LED lamp is in the ultra-negative heat working state, use the excitation devi...

Embodiment 2

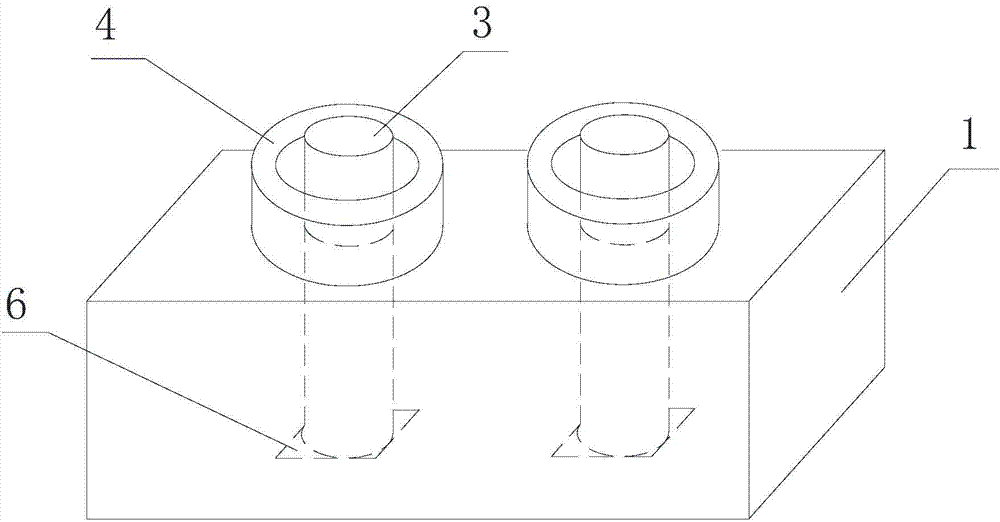

[0036] like figure 2 As shown, a heat removal and constant temperature structure of a high-power LED lamp includes: a flat gas-liquid conversion hollow cavity 1, an LED lamp bead 2, a magnetic working medium 3 and an excitation device 4; the LED lamp bead 2 is installed in the gas-liquid Invert one side of hollow chamber 1.

[0037] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the hollow round tube is omitted, and the magnetic working medium 3 corresponding to the LED lamp bead 2 is directly provided on the other side of the gas-liquid conversion hollow cavity 1. 3 penetrates into the gas-liquid conversion hollow cavity 1 and abuts against the installation part 6 of the LED lamp bead 2. The excitation device 4 corresponds to the magnetic working medium 3 and is used to excite and demagnetize the magnetic working medium 3 .

[0038] Compared with Embodiment 1, this embodiment sets one end of the magnetic working mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com