Industrial continuous production equipment and method for black phosphorus

A production equipment and black phosphorus technology, applied in the field of black phosphorus preparation, can solve the problems of difficult black phosphorus, difficult temperature and pressure control, harsh high temperature and high pressure conditions, etc., to achieve stable quality, prevent oxidation, and ensure purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

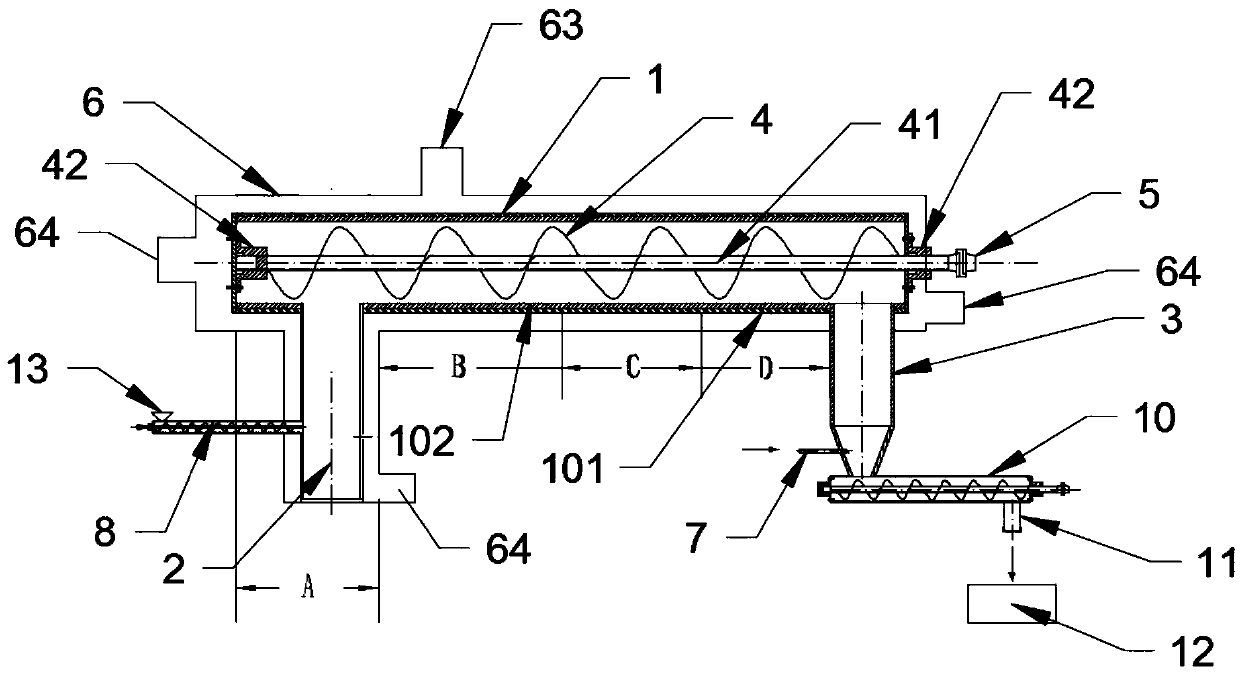

[0050] An industrialized continuous production equipment for black phosphorus, comprising a heat-resistant spiral conversion reactor 1, a feed pipe 2, a discharge pipe 3, a propeller blade 4, a motor 5, and a heating device 6; the feed pipe 2 is arranged on a heat-resistant One end of the spiral conversion reactor 1, the outlet pipe 3 is arranged below the other end; the heat-resistant spiral conversion reactor 1 is provided with a propeller blade 4; the propeller blade 4 is spirally mounted on a rotating shaft 41, and the rotating shaft 41 is arranged In the heat-resistant spiral conversion reactor 1, its two ends are connected with the heat-resistant spiral conversion reactor 1 through the bushing 42; the motor 5 is arranged at one end of the heat-resistant spiral conversion reactor 1 and is connected with the rotating shaft 41; The heat-resistant spiral conversion reactor 1 is provided with a heating device 6 outside, and the heating device 6 is wrapped outside the heat-resi...

Embodiment 2

[0064] An industrialized continuous production equipment for black phosphorus, characterized in that it comprises a heat-resistant spiral conversion reactor 1, a feed pipe 2, a discharge pipe 3, a propeller blade 4, a motor 5, and a heating device 6; the feed pipe 2 It is arranged at one end of the heat-resistant spiral conversion reactor 1, and the discharge pipe 3 is arranged below the other end; the heat-resistant spiral conversion reactor 1 is provided with a propeller blade 4; the propeller blade 4 is spirally installed on the rotating shaft 41 , the rotating shaft 41 is arranged in the heat-resistant spiral conversion reactor 1, and its two ends are connected with the heat-resistant spiral conversion reactor 1 through the bushing 42; connected; the heat-resistant spiral conversion reactor 1 is provided with a heating device 6, and the heating device 6 is wrapped around the heat-resistant spiral conversion reactor 1 and the feed port 2, and the heat-resistant spiral conver...

Embodiment 3

[0078] An industrialized continuous production equipment for black phosphorus, including a heat-resistant spiral conversion reactor 1, a feed pipe 2, a discharge pipe 3, a spiral

[0079] An industrialized continuous production equipment for black phosphorus, characterized in that it comprises a heat-resistant spiral conversion reactor 1, a feed pipe 2, a discharge pipe 3, a propeller blade 4, a motor 5, and a heating device 6; the feed pipe 2 It is arranged at one end of the heat-resistant spiral conversion reactor 1, and the discharge pipe 3 is arranged below the other end; the heat-resistant spiral conversion reactor 1 is provided with a propeller blade 4; the propeller blade 4 is spirally installed on the rotating shaft 41 , the rotating shaft 41 is arranged in the heat-resistant spiral conversion reactor 1, and its two ends are connected with the heat-resistant spiral conversion reactor 1 through the bushing 42; connected; the heat-resistant spiral conversion reactor 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com