A fully temperature-controlled electromagnetic clutch

An electromagnetic clutch, warm-type technology, applied in magnetic drive clutches, clutches, non-mechanical drive clutches, etc., can solve the problems of temperature rise, limited cooling range, inability to meet cooling requirements, etc., to achieve efficient heat absorption, ensure The effect of working stability and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

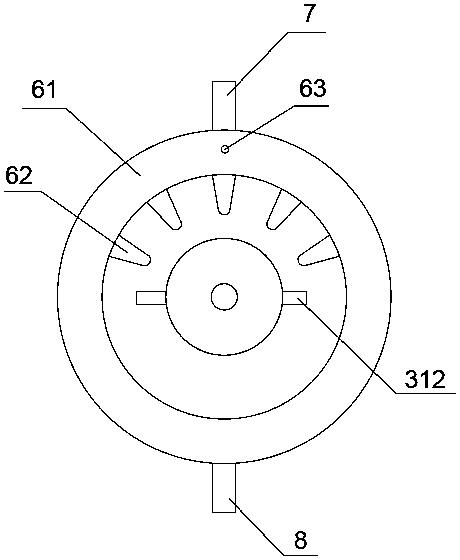

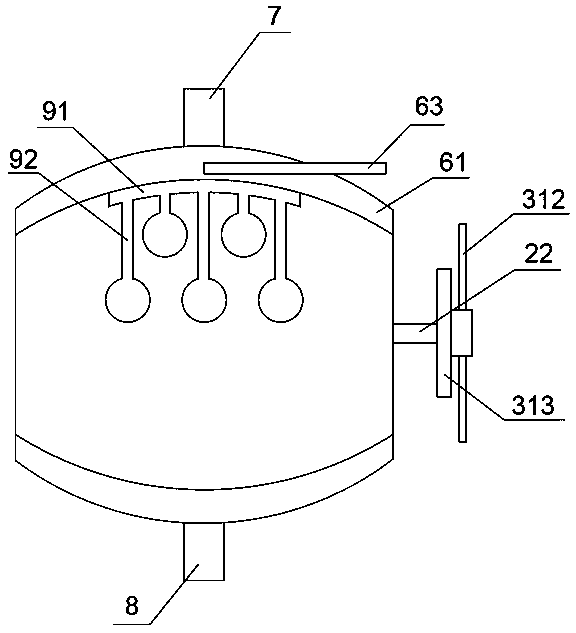

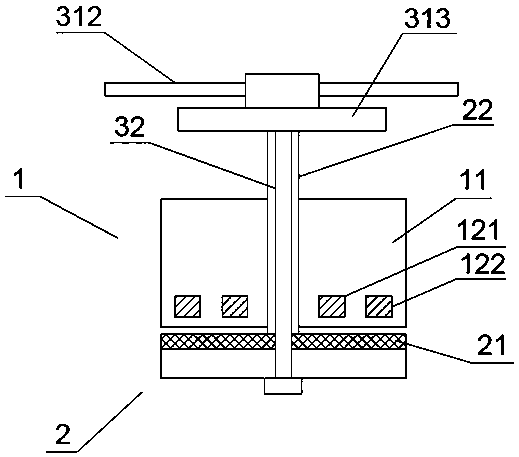

[0032] Example 1, such as Figure 1-5 As shown, the present invention includes a cooling assembly and a self-radiating assembly arranged outside the cooling assembly. The cooling assembly includes an active part 1, a driven part 2, a temperature control mechanism connected to the active part 1, and the The cooling mechanism connected to the driven part 2, the active part 1 includes a pulley 11, an electromagnet arranged in the pulley 11, the driven part 2 includes an armature 21, and a driving mechanism arranged in the middle of the armature 21. Shaft 22, the electromagnet includes an inner coil 121 and an outer coil 122; the temperature control mechanism includes a first temperature control switch connected to the outer coil 122 and a second temperature control switch connected to the inner coil 121; The cooling mechanism includes an air-cooling device connected to the drive shaft 22, a cooling pipe 32 arranged in the drive shaft 22 and connected to the air-cooling device; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com