An environment-friendly aerated brick cutting system

A technology of cutting system and aerated bricks, which is applied in the direction of climate sustainability, stone processing tools, stone processing equipment, etc., can solve the problems of manpower consumption, cumbersome operation, and high panel height, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

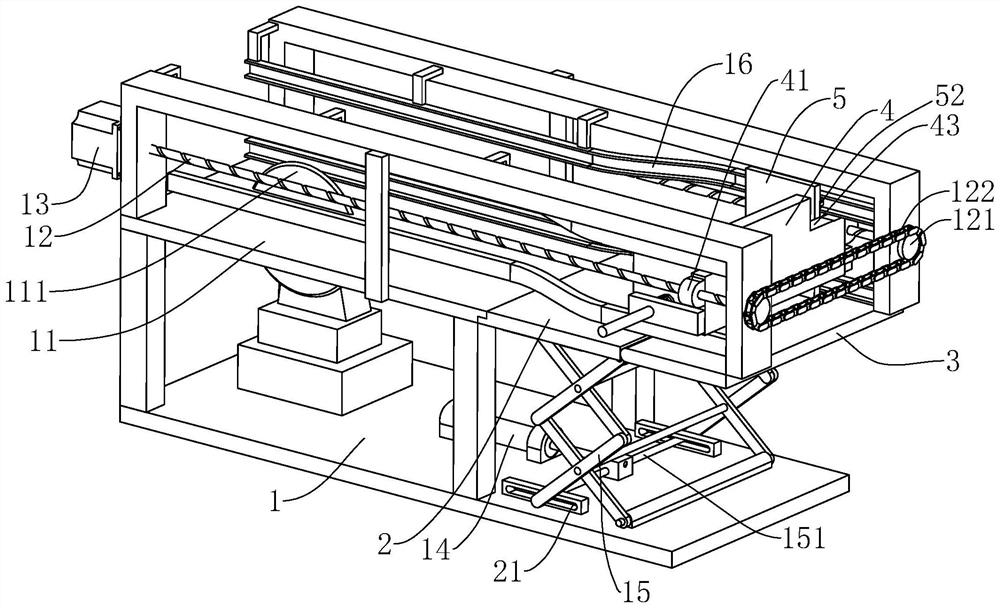

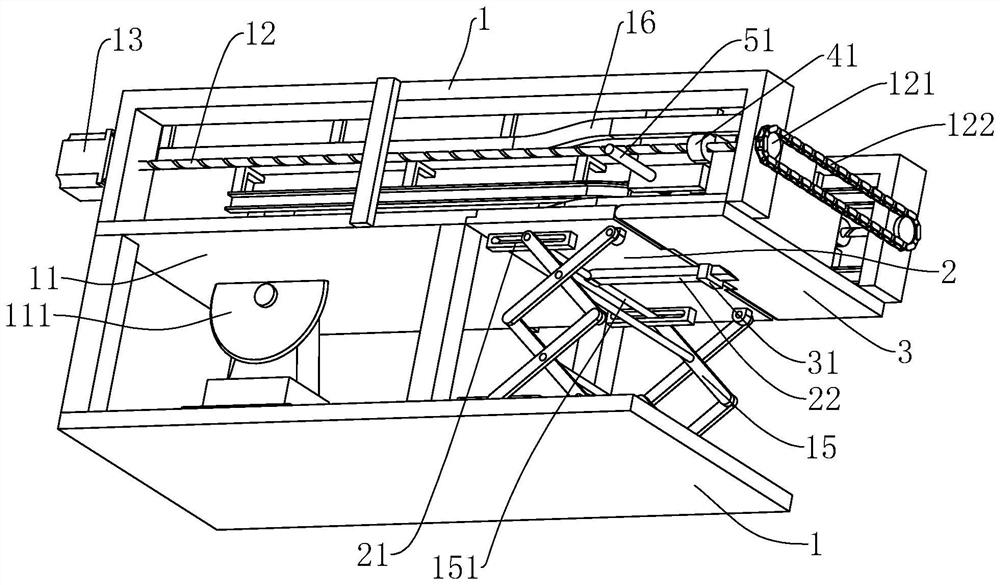

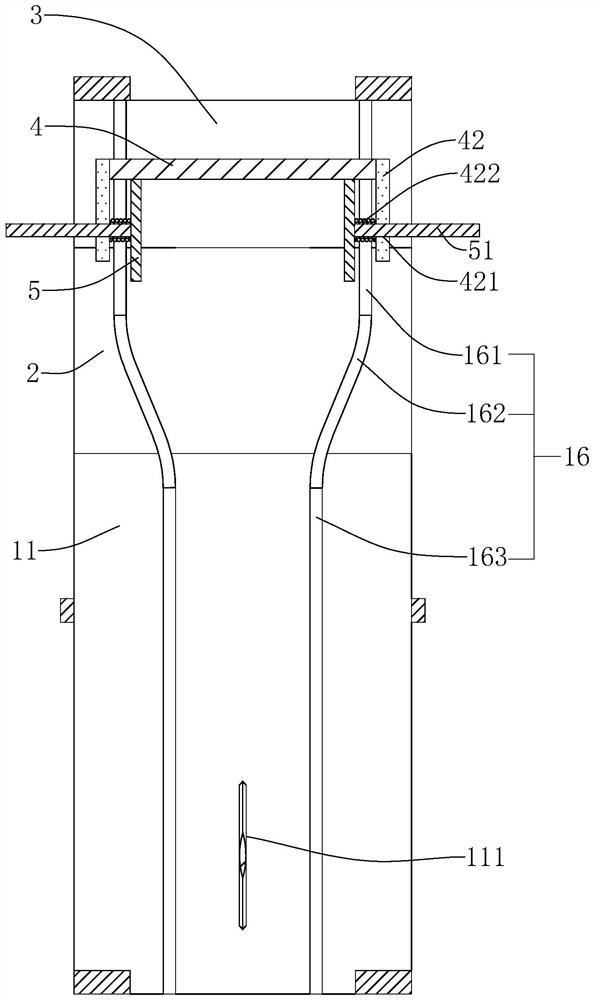

[0033] The following is attached Figure 1-3 The application is described in further detail.

[0034] The embodiment of this application discloses an environment-friendly aerated brick cutting system, refer to figure 1, the cutting system includes a frame 1 and a cutting table 11 horizontally installed above the frame 1, a cutting knife 111 is installed in the middle of one side of the cutting table 11, and a horizontal lifting table 2 is provided on the side of the cutting table 11 away from the cutting knife 111 One side of the lifting platform 2 is flush with and connected to the cutting platform 11, and the aerated bricks to be cut can be placed on the upper surface of the lifting platform 2.

[0035] refer to figure 1 and figure 2 The frame 1 is equipped with a lifting mechanism that drives the lifting platform 2 to move up and down. The lifting mechanism includes a combined folding rod 15 connected in a scissors-like rotation and a cylinder 14 fixed to the frame 1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com