Denitration catalyst and method for preparing denitration catalyst from waste denitration catalyst

A technology of waste denitration catalyst and denitration catalyst, which is applied in the field of denitration catalyst, can solve the problems of difficult removal of catalyst poisoned metals, complex recovery process, and low catalyst life, so as to achieve less secondary pollution, simple process flow, and simplified process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

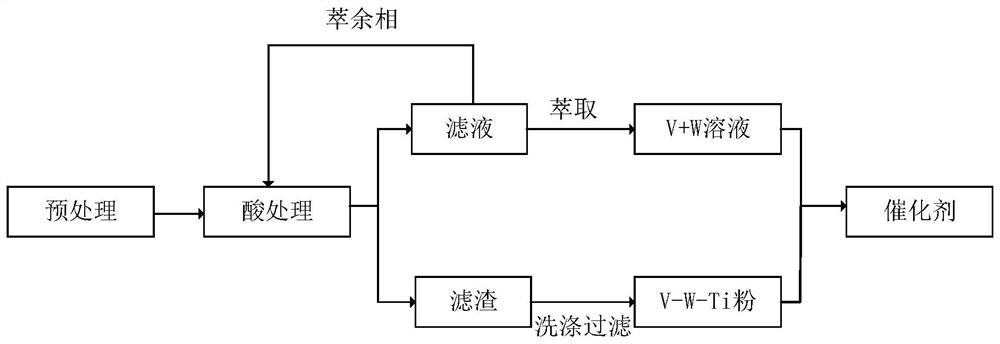

Method used

Image

Examples

Embodiment 1

[0116] 1) Grind 100 g of the spent denitration catalyst until the particle size is between 300 and 500 mesh, and then add 200 ml of H2O with a mass concentration of 90 wt % 2 SO 4 solution, reacted at 150°C for 3 hours, and then filtered to obtain filtrate and filter residue.

[0117] 2) Wash the filter residue in step 1) with deionized water until the pH of the filtrate is 1.5, then centrifuge, and dry the filter cake in an oven at 120° C. for 24 hours.

[0118] 3) Use alkali to adjust the pH value of the filtrate in step 1) to 3.0, use N235 as the extractant, O / A=1:8, centrifuge the extract, adjust the pH of the extract to about 10 with ammonia water, add 4M Back extraction with ammonia water, O / A=2:1, to obtain vanadium + tungsten mixed solution.

[0119] 4) Pulverize the vanadium-tungsten-titanium powder obtained in step 1) to about 300 meshes, and then add the obtained vanadium+tungsten mixed solution, water, binder, lubricant, pore-forming agent, surfactant, and struct...

Embodiment 2

[0122] Adopt the method identical with embodiment 1 to carry out, difference is: step 1) add the H of 600ml mass percentage 80wt% 2 SO 4 solution, and reacted at 190°C for 1 hour. Step 2) washing with deionized water until the pH of the filtrate is 2.0.

Embodiment 3

[0124] Adopt the method identical with embodiment 1 to carry out, difference is: step 1) add the H of 400ml mass percent 70wt% 2 SO 4 solution, and reacted at 200°C for 5 hours. Step 2) washing with deionized water until the pH of the filtrate is 2.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com