Preparation method of anti-puncture breathable sole and safety shoe with sole

A technology of air shoes and foam, which is applied to shoe soles, footwear, footwear, etc. It can solve the problems of unreasonable design of the anti-puncture structure of labor insurance shoes and the inability to take into account air permeability, etc., and achieve good anti-peeling effect, strong resistance Piercing effect, secure connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

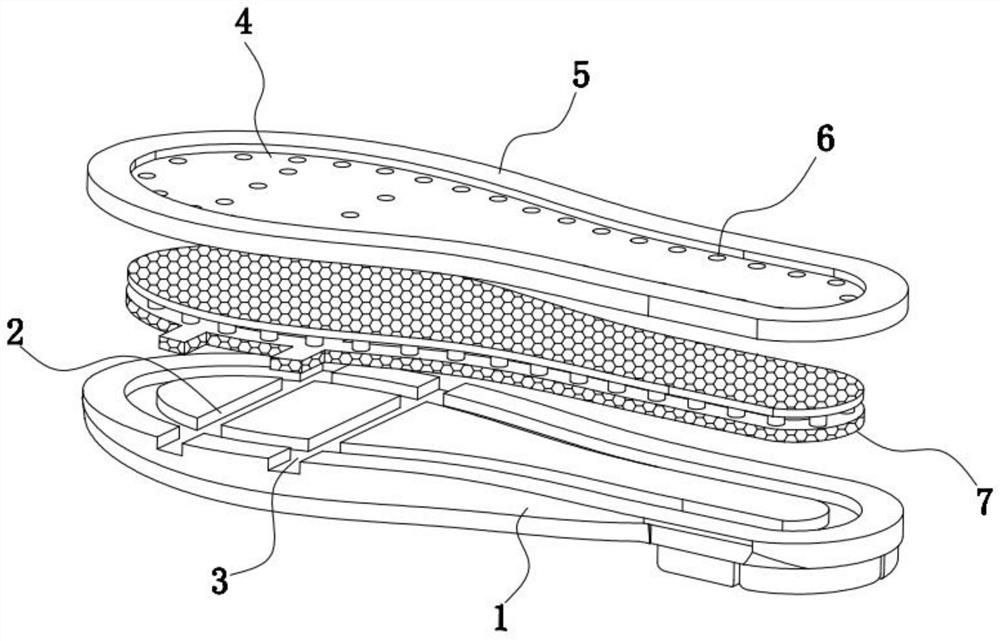

[0029] Such as figure 1 Shown, a kind of preparation method of puncture-resistant breathable sole comprises the following steps:

[0030] S1: Dissolve aluminum nitrate and malic acid in deionized water and heat up to 85°C, then add spinning additive PVP and stir for 12 minutes, then add acrylic resin and carbon nanotubes to it, and heat to After treatment at 100°C, ultrasonically stir for 2 hours, then concentrate the mixed solution and cool it to room temperature to obtain a spinning solution;

[0031] S2: The spinning solution is processed by a centrifugal spinning machine, and centrifugally spun at 2000 rpm and 65°C, and then the spun fibers are dried in an oven at 60°C for 18 hours, and then sintered at 1200°C for 1 hour to obtain composite fibers;

[0032] S3: Mix and heat polyol, catalyst, foaming agent, carbon fiber powder, chain extender, foam stabilizer and composite fiber to 110°C, then add isocyanate and diffuse by ultrasonic for 2 hours, and pour into different mo...

Embodiment 2

[0035] Such as figure 1 Shown, a kind of preparation method of puncture-resistant breathable sole comprises the following steps:

[0036] S1: Dissolve aluminum nitrate and malic acid in deionized water and heat up to 85°C, then add spinning additive PVP and stir for 12 minutes, then add acrylic resin and carbon nanotubes to it, and heat to After treatment at 100°C, ultrasonically stir for 2 hours, then concentrate the mixed solution and cool it to room temperature to obtain a spinning solution;

[0037] S2: The spinning solution is processed by a centrifugal spinning machine, and centrifugally spun at 2000 rpm and 65°C, and then the spun fibers are dried in an oven at 60°C for 18 hours, and then sintered at 1200°C for 1 hour to obtain composite fibers;

[0038] S3: Mix and heat polyol, catalyst, foaming agent, carbon fiber powder, chain extender, foam stabilizer and composite fiber to 110°C, then add isocyanate and diffuse by ultrasonic for 2 hours, and pour into different mo...

Embodiment 3

[0041] Such as figure 1 Shown, a kind of preparation method of puncture-resistant breathable sole comprises the following steps:

[0042] S1: Dissolve aluminum nitrate and malic acid in deionized water and heat up to 85°C, then add spinning additive PVP and stir for 12 minutes, then add acrylic resin and carbon nanotubes to it, and heat to After treatment at 100°C, ultrasonically stir for 2 hours, then concentrate the mixed solution and cool it to room temperature to obtain a spinning solution;

[0043] S2: The spinning solution is processed by a centrifugal spinning machine, and centrifugally spun at 2000 rpm and 65°C, and then the spun fibers are dried in an oven at 60°C for 18 hours, and then sintered at 1200°C for 1 hour to obtain composite fibers;

[0044] S3: Mix and heat polyol, catalyst, foaming agent, carbon fiber powder, chain extender, foam stabilizer and composite fiber to 110°C, then add isocyanate and diffuse by ultrasonic for 2 hours, and pour into different mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com