Steel building formwork with metal outer frame

A technology of building formwork and outer frame, which is used in construction, building structure, formwork/formwork components, etc., can solve the problems of short life, inability to protect joints, easy to fall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

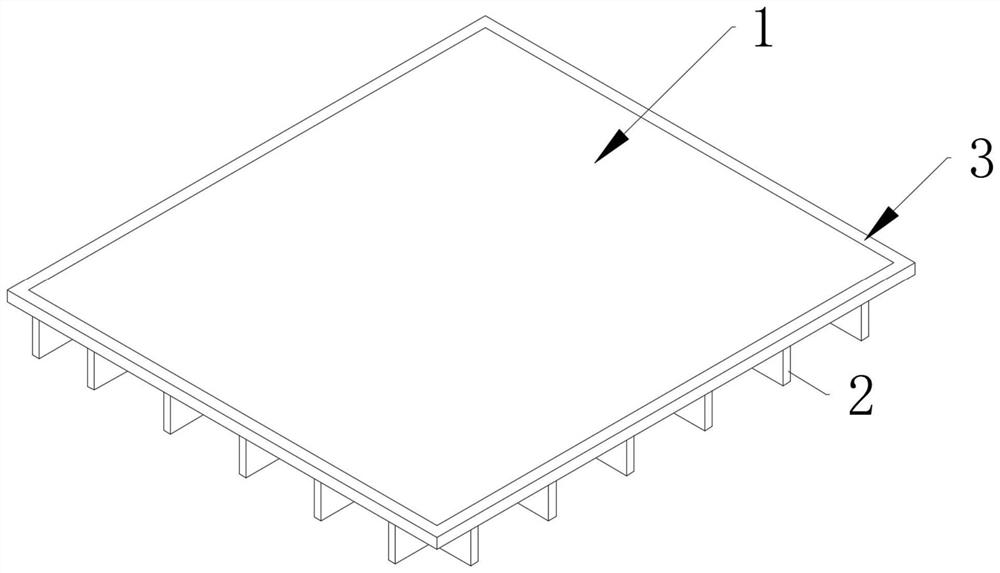

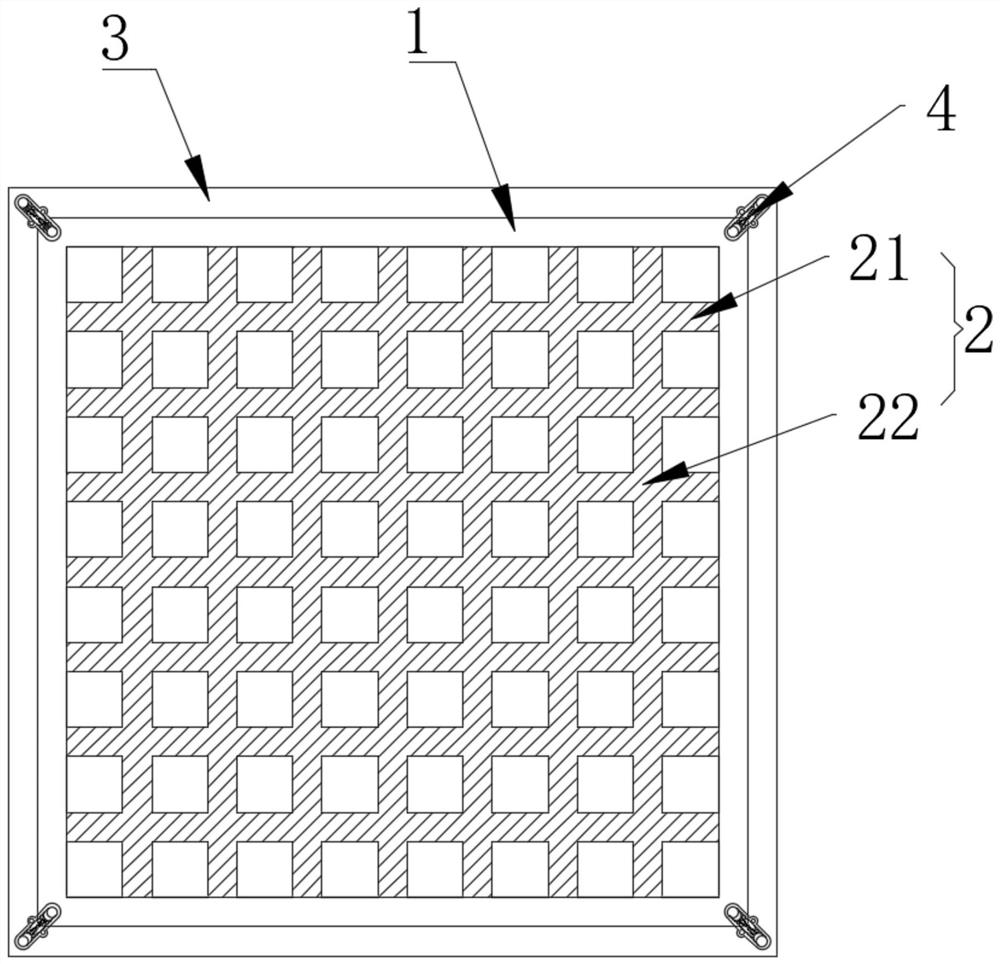

[0028] see Figure 1-4 , the present invention provides a technical solution: a steel building formwork with a metal outer frame, including a formwork panel 1, the bottom of the formwork panel 1 is fixedly connected with a well-shaped reinforcing rib 2, and the outside of the formwork panel 1 is fixedly connected with a metal The outer frame 3, the lower part of the metal outer frame 3 and the four corners of the template panel 1 are all provided with a connection stabilization mechanism 4;

[0029] The well-shaped reinforcing rib 2 includes a transverse reinforcing rib 21 and a vertical reinforcing rib 22, and the transverse reinforcing rib 21 and the vertical reinforcing rib 22 are fixedly connected in a criss-cross pattern.

Embodiment 2

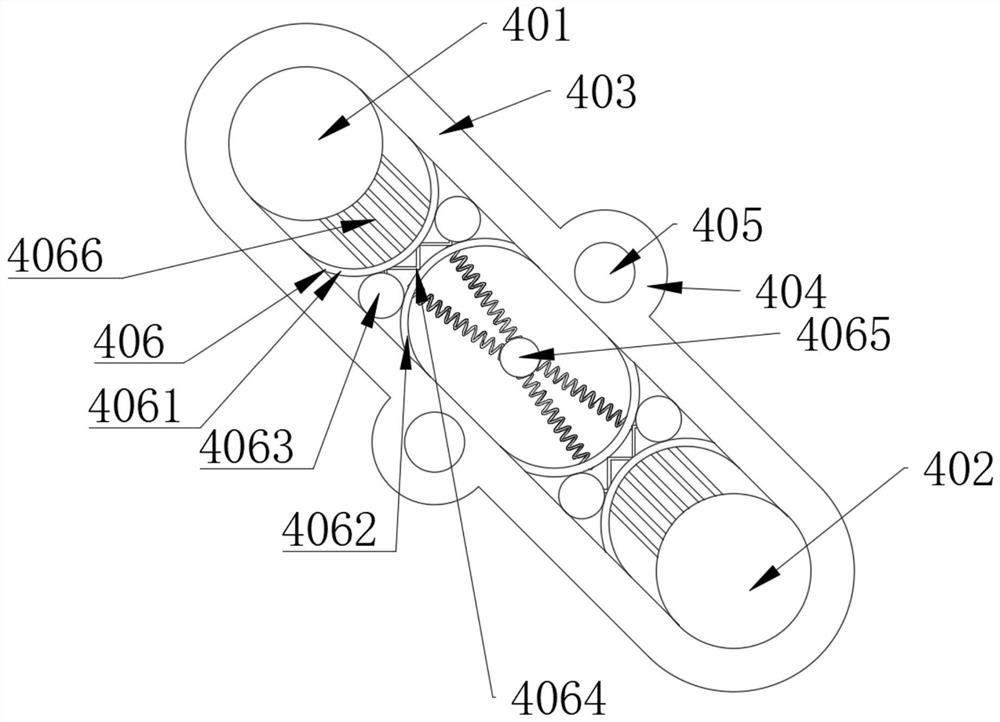

[0031] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the connection stabilization mechanism 4 includes four first connection shafts 401 and four second connection shafts 402, and the first connection shafts 401 are fixedly connected to the metal outer frame 3 At the four corners, the second connection shaft 402 is fixedly connected to the four corners of the template panel 1, and a ring-shaped elastic belt 403 is fixedly connected between two groups of adjacent first connection shafts 401 and second connection shafts 402. The center of the belt 403 is fixedly connected with an annular connecting seat 404, and the bottom of the annular connecting seat 404 is fixedly connected on the metal outer frame frame 3 through fixing bolts 405, and two groups of axisymmetrically arranged ring-shaped elastic belts 403 are fixedly connected between the inner walls The impact buffer mechanism 406 of the metal outer frame 3 and the formwork...

Embodiment 3

[0033] see Figure 1-4 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the impact buffer mechanism 406 includes a first arc-shaped plate 4061 and a second arc-shaped plate 4062, and the first arc-shaped plate 4061 and the second arc-shaped plate 4061 Both ends of the arc-shaped plate 4062 are fixedly connected to the inner wall of the annular elastic band 403, and shock-absorbing balls 4063 are fixedly connected between the first arc-shaped plate 4061 and the second arc-shaped plate 4062 and the inner wall of the annular elastic band 403, A folding fan-type elastic plate 4064 is fixedly connected between the two shock-absorbing balls 4063, and a secondary protection mechanism 4065 is arranged between the two opposite second arc-shaped plates 4062. Through the setting of the impact buffer mechanism 406, when an impact or When falling, the first arc-shaped plate 4061 and the second arc-shaped plate 4062 provide stress, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com