Self-suction microfluid fuel cell based on paper-wrapped electrode

A fuel cell and self-priming technology, which is applied in the direction of aqueous electrolyte fuel cells, fuel cell additives, battery electrodes, etc., can solve the problems of limiting the application of microfluidic fuel cells, increasing system complexity, and low flow rate of reaction liquid, etc., to achieve The effect of shortening the ion movement path, reducing internal resistance, and increasing the reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

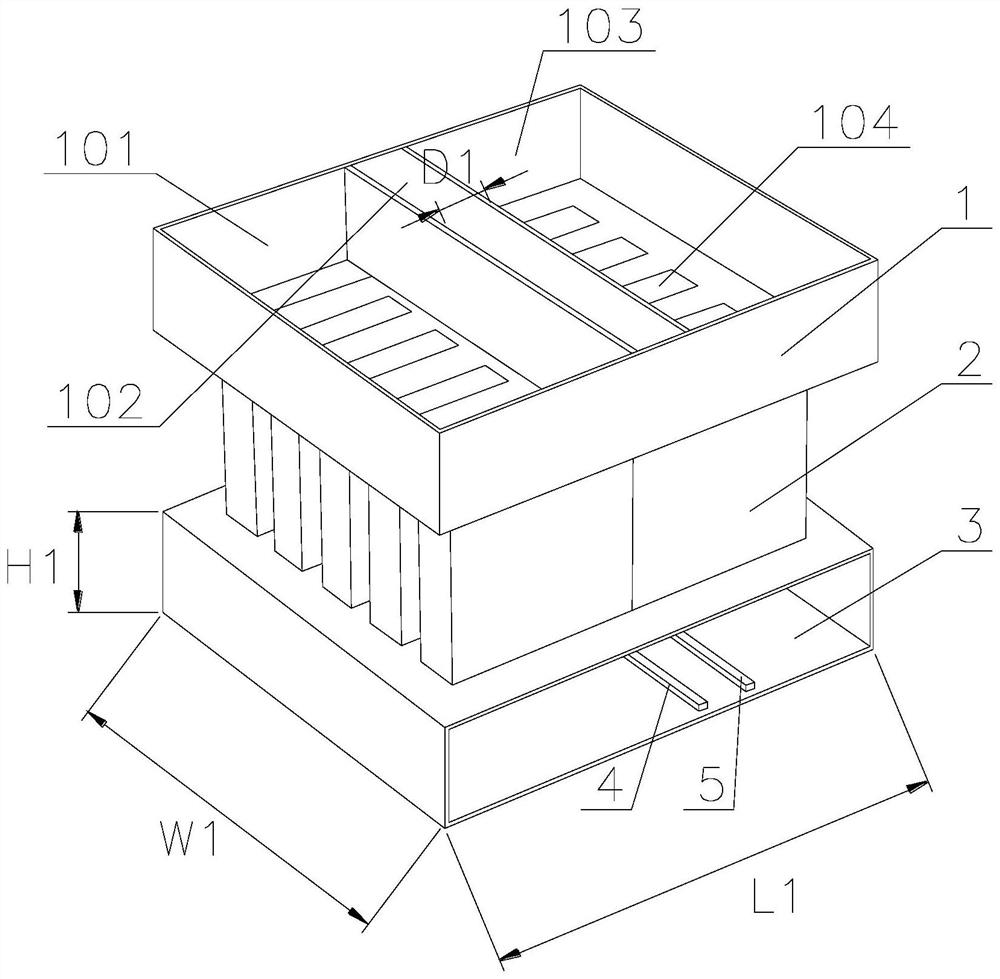

[0025] The present invention will now be described in detail with reference to the drawings. This figure is a schematic diagram of the present invention, and therefore only the configurations related to the present invention are shown in schematic.

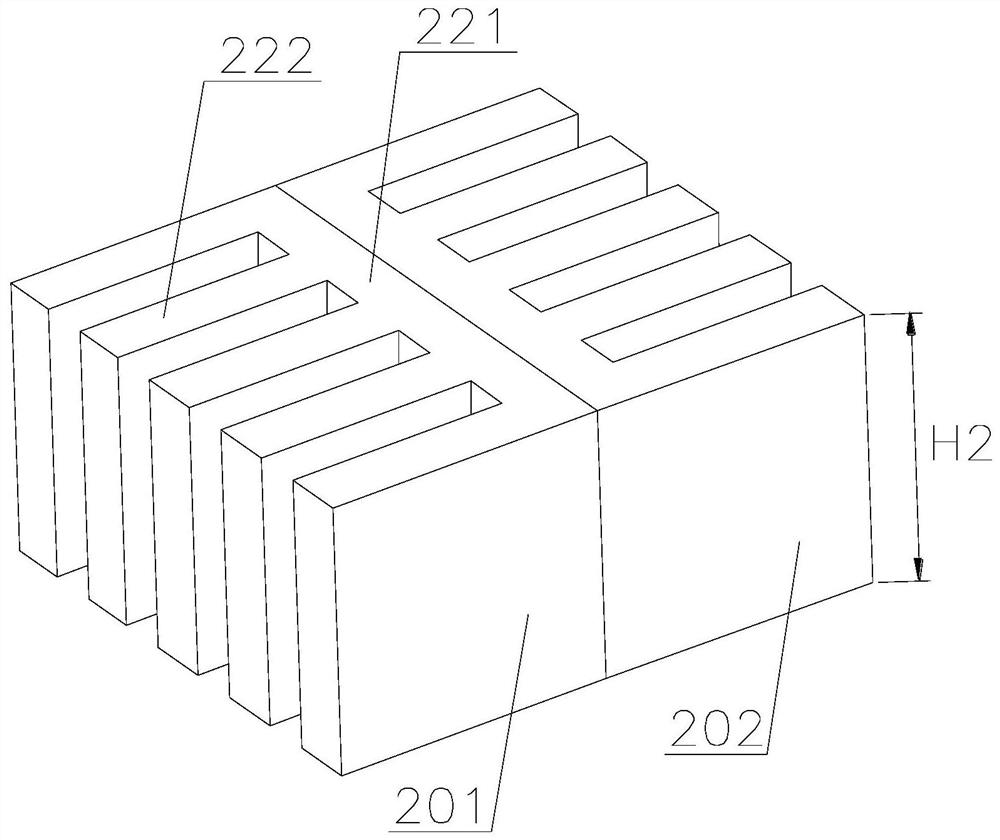

[0026] Such as Figure 1-4 As shown, the present invention is a self-suction microfluidic fuel cell based on a paper-packet electrode comprising a reservoir 1, a paper bag electrode 2, and an absorbing box 3 disposed from top, and the paper packet electrode 2 comprises an anode. 201 and cathode 202, the anode 201 and the cathode 202 are bonded to each other, and the anode 201 and the cathode 202 are graphite core 211, the anode 201 and the outer wall surface of the anode 201 and the cathode 202 coated with a porous filter paper 213, the anode 201 Including the main body portion 221, the anode 201 main body portion 221 extends with a comb teeth 222 from one side of the cathode 202, which is the same as the anode 201, and the cathode 202...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com