Bismuth scandate-lead titanate-bismuth ferrite ternary system piezoelectric ceramic and acoustic emission sensor thereof

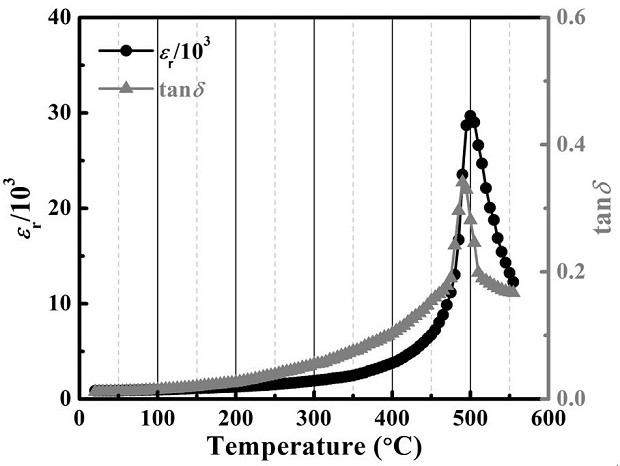

An acoustic emission sensor and ceramic technology, which is applied in the field of high temperature sensing, can solve the problem that the solid solution cannot meet the high temperature service environment of 300 ° C, and achieve the effect of excellent piezoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

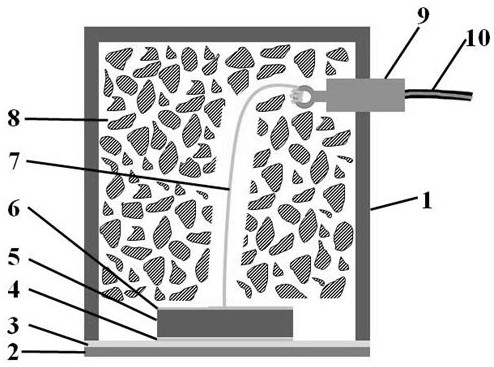

[0046] High-temperature piezoelectric ceramic sheets are used as piezoelectric elements, and the content of Al 2 o 3 99% Al with a diameter of 18 mm and a thickness of 1 mm 2 o 3 The ceramic is the sound-transmitting layer, the silver powder conductive adhesive is the high-temperature conductive adhesive and binder, the Pt metal layer is the upper and lower electrode layers of the chip, and the porous ZrO 2 for sound-absorbing materials.

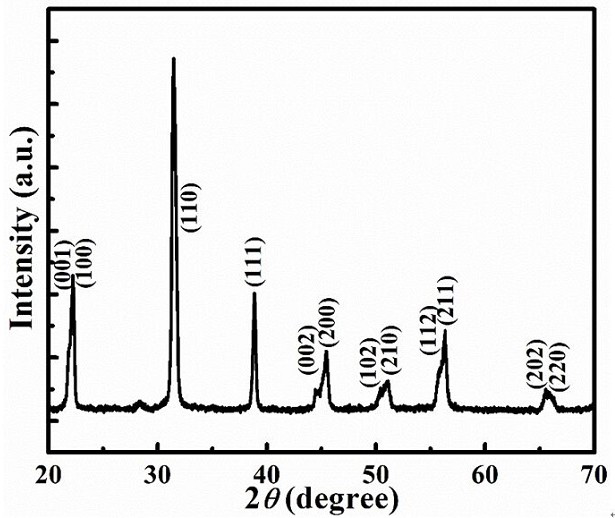

[0047] Among them, the ceramic is 0.33Bi 0.991 La 0.009 ScO 3 -0.62PbTiO 3 -0.05Bi 0.999 La 0.001 Fe 0.95 Ga 0.05 o 3 -1mol%Mn high temperature piezoelectric ceramics. With analytically pure raw material Bi 2 o 3 、Sc 2 o 3 , PbO, TiO 2 , La 2 o 3 , Fe 2 o 3 , Ga 2 o 3 , MnO 2 According to the stoichiometric ratio of ingredients, add ethanol, the amount of ethanol added is 25mL / 10g of the mixture, put it into a ball mill jar and mill it for 24 hours to mix evenly; after mixing evenly, put the mixture in an oven and dry...

Embodiment 2

[0051] High-temperature piezoelectric ceramic sheets are used as piezoelectric elements, and the content of Al 2 o 3 99% Al with a diameter of 18 mm and a thickness of 1 mm 2 o 3 The ceramic is the sound-transmitting layer, the silver powder conductive adhesive is the high-temperature conductive adhesive and binder, the Pt metal layer is the upper and lower electrode layers of the chip, and the porous ZrO 2 It is a high-temperature sound-absorbing material.

[0052] Among them, the ceramic is 0.3Bi 0.992 La 0.008 ScO 3 -0.6PbTiO 3 -0.1Bi 0.998 La 0.002 Fe 0.95 Ga 0.05 o 3 -1mol%Mn high temperature piezoelectric ceramics. With analytically pure raw material Bi 2 o 3 、Sc 2 o 3 , PbO, TiO 2 , La 2 o 3 , Fe 2 o 3 , Ga 2 o 3 According to the stoichiometric ratio of ingredients, add ethanol, the amount of ethanol added is 25mL / 10g of the mixture, put it into a ball mill jar and mill it for 24 hours to mix evenly; after mixing evenly, put the mixture in an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com