A natural symbiotic mixed culture method for degrading roughage to produce citric acid

A technology for culture and roughage, applied in the field of biotechnology renewable energy, can solve the problems of citric acid and low yield of citric acid, and achieve the effects of preventing bacterial contamination, facilitating promotion and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one, the preparation of mixed culture YakQH5 microbial agent

[0029] Draw 1 mL of the mixed culture YakQH5 and inoculate it into 9 mL of anaerobic medium with air-dried and pulverized wheat straw as the substrate in a Heinz anaerobic tube, and at the same time add 0.1 mL of compound antibiotics (1600 IU / mL penicillin and 2000 IU / mL streptomycin sulfate ), anaerobic culture at 39°C for 72 hours, the growth peak is reached, and the fermentation broth is a high-vigor bacterial agent at this time.

Embodiment 2

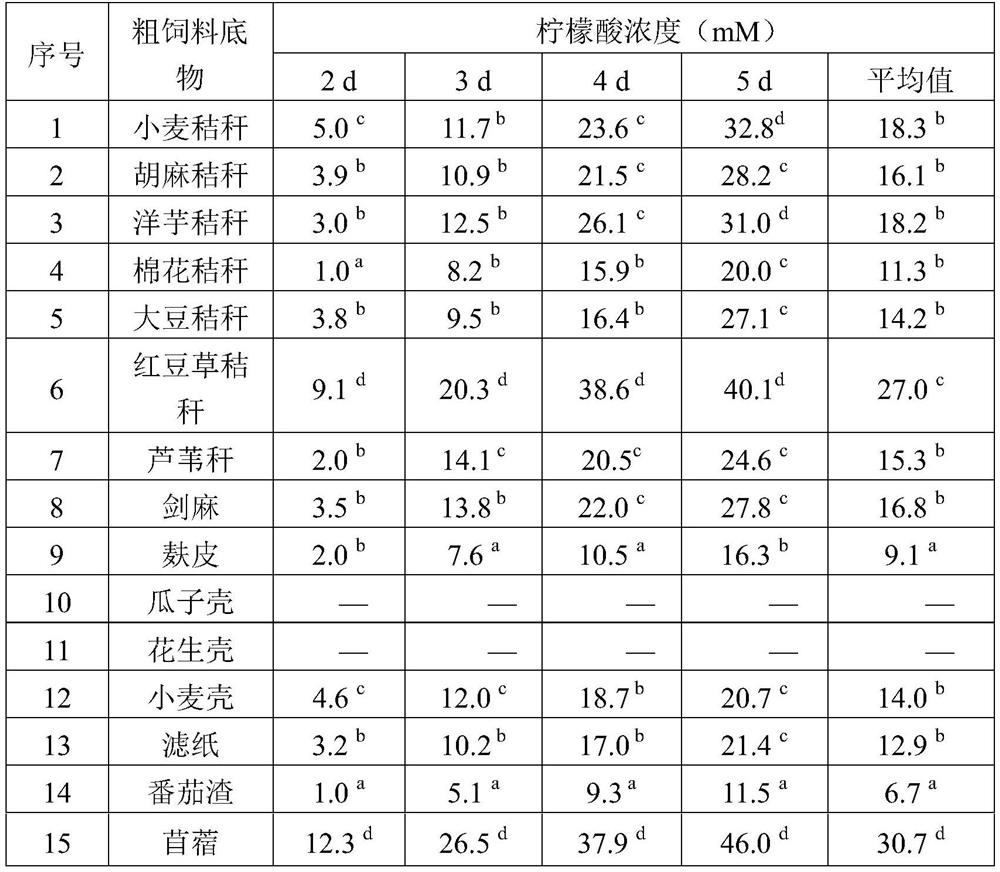

[0030] Embodiment two, mixed culture YakQH5 fermentation produces citric acid

[0031] Put 45mL of liquid basic medium in a 100mL anaerobic fermentation bottle, and use 0.5g of crushed air-dried wheat straw, flax straw, artichoke straw, cotton straw, soybean straw, red bean grass straw, reed straw, sisal, bran A total of 15 kinds of roughages including husks, melon seed hulls, peanut hulls, wheat hulls, filter paper, tomato pomace and alfalfa were used as substrates. Deoxygenation. Sterilize. Inoculate 5 mL of the mixed culture YakQH5 subcultured for 72 hours into the above-mentioned anaerobic medium with various roughages, and add 0.5 mL of compound antibiotics (1600 IU / mL penicillin and 2000 IU / mL streptomycin sulfate) , anaerobic culture at 39°C for 5 days. A total of 3 parallel experiments were set up, and the concentration of citric acid in the anaerobic bottle was measured every 24 hours. Determination of citric acid by liquid chromatography:

[0032] Use a liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com