An antibacterial coil coating with water resistance

A coil coating and performance technology, used in antifouling/underwater coatings, polyester coatings, coatings, etc., can solve problems such as changes in resin structure and coating performance, and achieve the effect of preventing changes in network structure characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

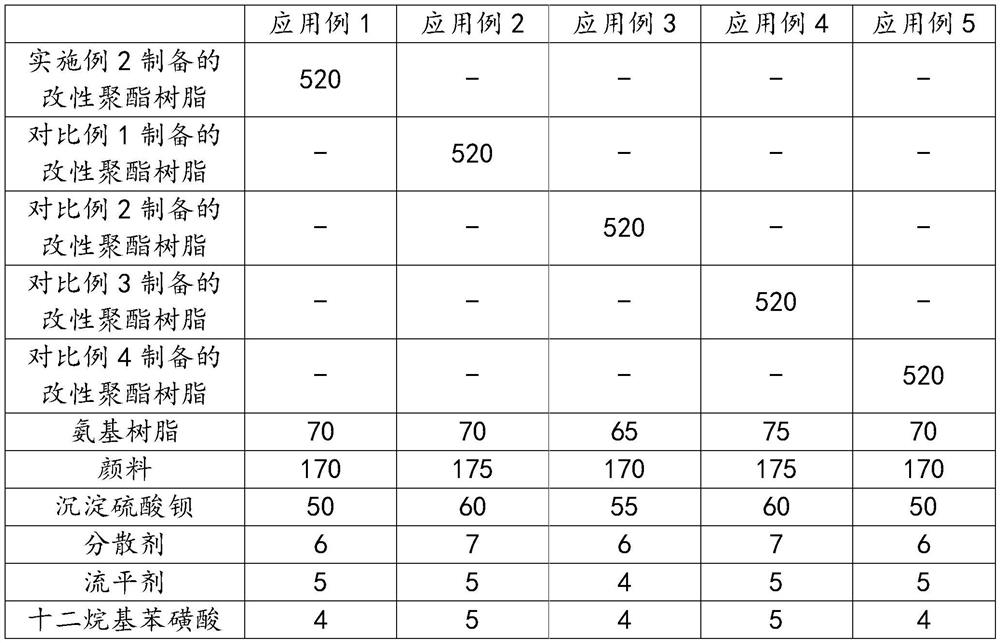

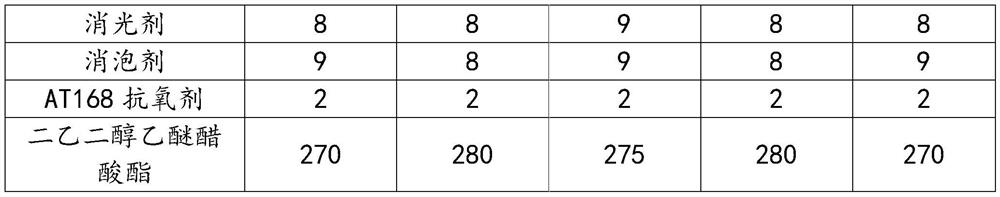

Examples

Embodiment 1

[0030] The preparation process of dislocation antibacterial enhancer is as follows:

[0031] Step 1: Add 1mol of p-thiaminophenol and 600mL of ethanol to the reaction kettle at the same time, stir and dissolve, then add 1.25mol of propynyl alcohol to it, stir and mix at room temperature for 50 minutes, then raise the temperature to 80°C, add 0.7mol of manganese dioxide to it, and then add 0.7mol of manganese dioxide to it at 2MPa Continuously feed air into the reactor under the pressure of 100°C. After the reaction is completed, the manganese dioxide is filtered off, and the obtained filtrate is subjected to rotary evaporation to remove the solvent and excess propynyl alcohol to obtain ammoniated allyl aldehyde phenol; ammoniated alkene Propionylphenol 1 Spectral analysis of HNMR, δ=5.74ppm and δ=7.32ppm are alkene groups 1 Absorption peak of H, δ=9.68ppm aldehyde group 1 H absorption peak;

[0032] Step 2: Add 1 mol of ammoniated allyl aldehyde phenol and 600 mL of carbon ...

Embodiment 2

[0035] The concrete preparation process of modified polyester resin is as follows:

[0036] In the first step, add 1 mol of adipic acid into 150mL of benzene and stir to dissolve, then raise the temperature to 75°C, add 100mL of bromine and 4.8mL of phosphorus trichloride dropwise, and heat the reaction at constant temperature until no red bromine vapor appears. Then slowly raise the temperature to 105°C, and then keep it warm for 3.5 hours, then carry out vacuum distillation and cooling crystallization on the product to obtain brominated adipic acid; brominated adipic acid 1 Spectrum analysis of HNMR, δ=4.23ppm and δ=12.22ppm are carboxyl groups 1 H absorption peak;

[0037] In the second step, 1mol of 4-aminoacetophenone, 50mL of acetic acid solution with a mass concentration of 35% and 160mL of ethanol are simultaneously added to the reaction kettle and stirred to dissolve, and then 2.4mol of propylene oxide is added dropwise at 5°C, and the mixture is controlled within 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com