Acetal production equipment and using method thereof

A technology for acetaldehyde diethyl acetal and production equipment, which is applied in the chemical industry and can solve the problems of reduced yield, trouble and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

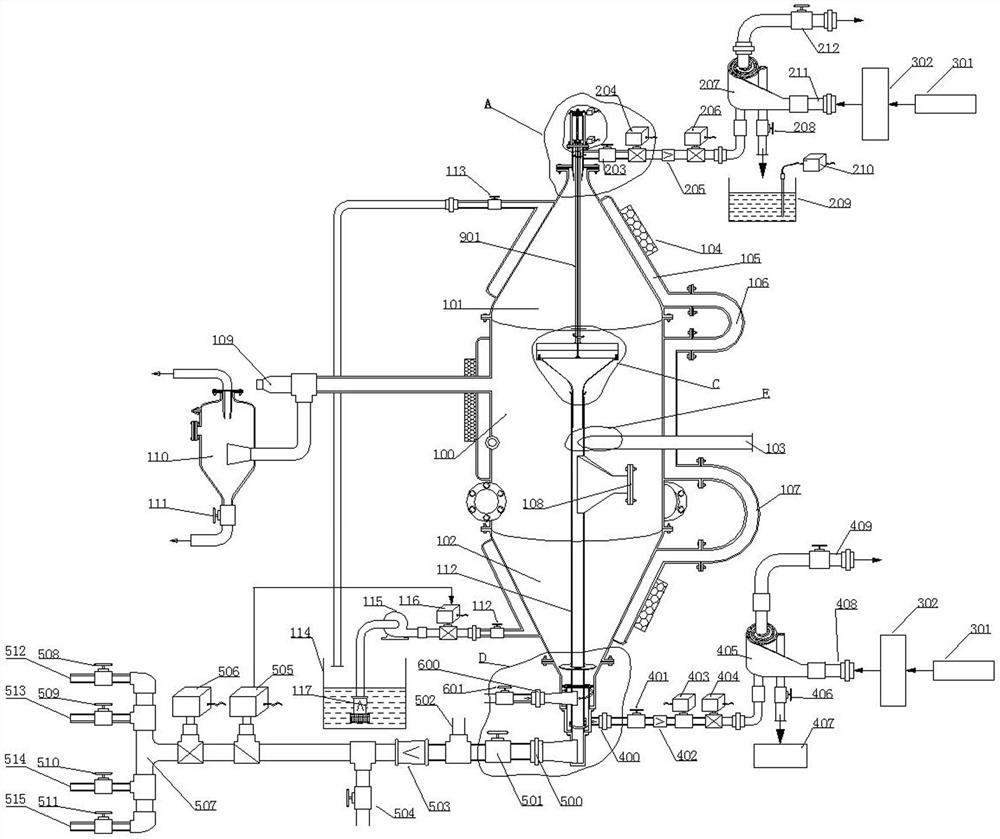

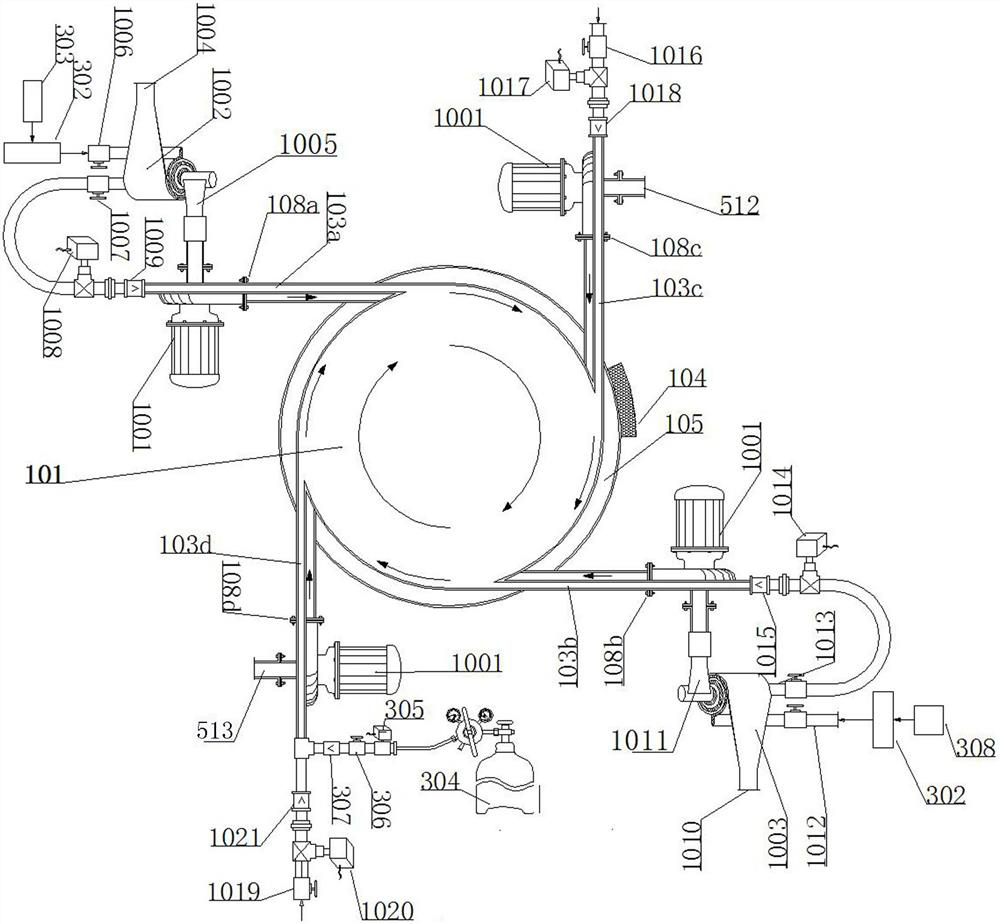

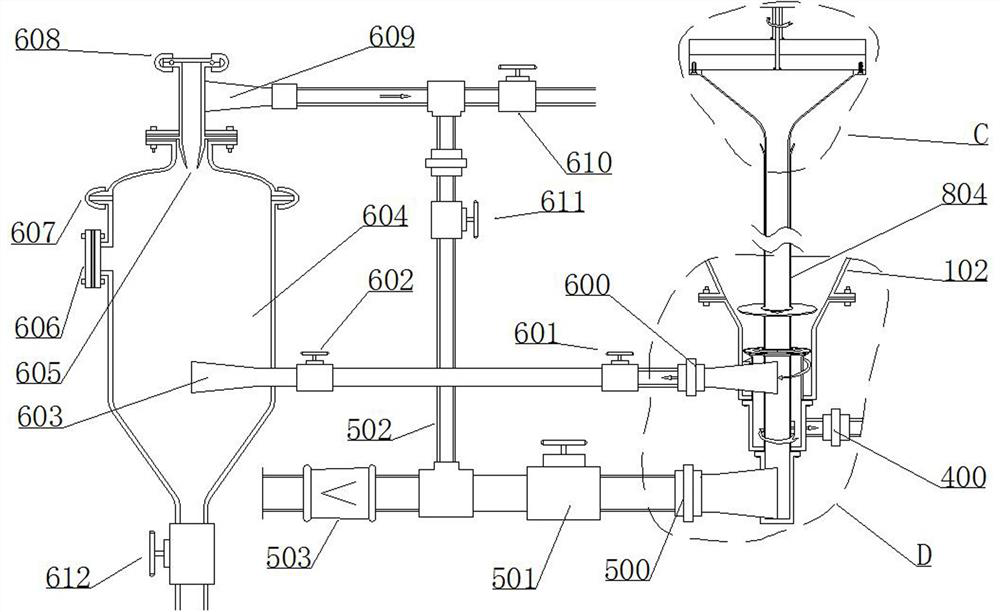

[0123] Embodiment 1 (the position of the collection port of the circulating reaction fluid is: axial 16cm, radial 76°)

[0124] 1. Equipment selection

[0125] 1. Key data of anti-tank separation:

[0126] Cylindrical section 100 has a diameter of 2m and a height of 0.5m, the upper circular platform section 101 has a height of 0.6m, and the lower circular platform section 102 has a height of 0.4m and a volume of 2.618m 3 . The r of the collection port 202 1 is 4.30cm, r 2 is 2.47cm, the r of the circulating fluid collection port 809 1 is 32.73cm, r 2 is 16.99cm, the r of the third collecting tube 703 1 18.76cm, r 2 is 13.71cm, the r of the second collection tube 702 1 is 12.99cm, r 2 The diameter of the first blocking disc 704 is 42.9 cm, and the diameter of the second blocking disc 705 is 26.4 cm.

[0127] 2. Supporting equipment: 3 plunger pumps (2.0L / min, power 200w) for feeding anhydrous ethanol, 1 plunger pump (2.0L / min, power 200w) for feeding acetaldehyde; plu...

Embodiment 2

[0163] Embodiment 2: The position of the collection port of the circulating reaction fluid is: 17.5 cm in the axial direction and 87° in the radial direction

[0164] 1. Reaction temperature, pressure, raw material ratio after realizing continuous reaction, operation process and gas chromatography analysis method are the same as in Example 1, the difference is that on the basis of Example 1, focus on adjusting the collection of circulating reaction fluid mouth position, in order to fully excavate the best operating conditions of the equipment.

[0165] 2. Let the axial reading of the circulating reaction fluid collection port 809 be Z, and take its lowest point as "z=0"; the radial reading is J, taking Figure 7 (c) is "j=0°", then the position of the circulating fluid collection port 809 in Embodiment 1 is a point (Z=16cm, J=76°). Starting from the point (Z=16cm, J=76°), first fix the J value, and measure a point every "1cm" of the Z value. When Z=17cm, through gas chromato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com