Ceramic-carbonate compact double-phase inorganic membrane taking ceramic material as support body

A technology of ceramic materials and carbonates, applied in the direction of inorganic chemistry, membrane technology, carbon compounds, etc., can solve the problems of consuming large load energy, increasing the cost of production and reducing emissions, etc., to save load energy and save the cooling process , Expand the effect of the application environment and field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

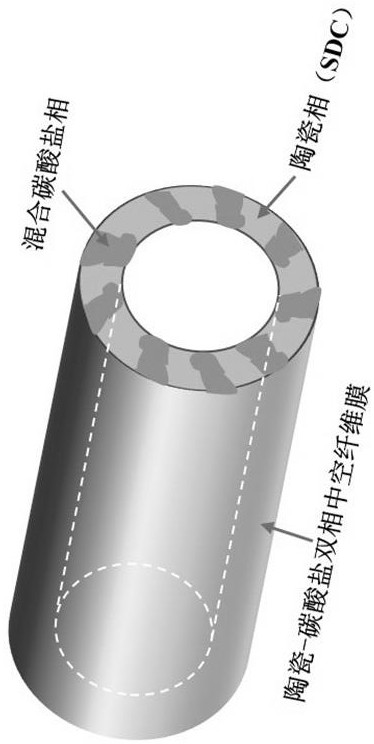

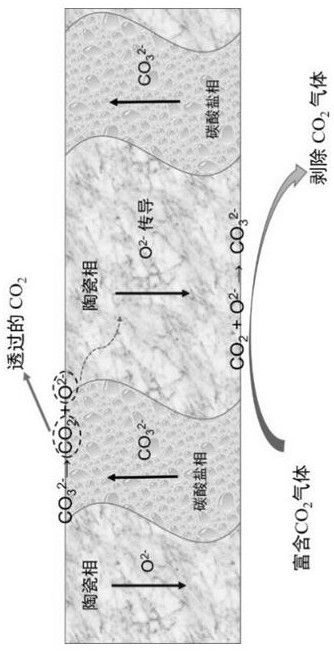

[0017] Such as figure 1 As shown, a ceramic-carbonate dense dual-phase inorganic membrane with ceramic material as a support body, the inorganic membrane contains two phases, one phase is a ceramic phase as a support body, and the other phase is a carbonate phase; ceramic The material of the phase is samarium oxide doped with cerium oxide (Sm 2 o 3 doped-CeO 2 , SDC), the carbonate phase is a mixed carbonate; the carbonate phase is a mixed carbonate composed of lithium carbonate and sodium carbonate, and the mixing ratio of lithium carbonate and sodium carbonate is 52:48 mol%.

[0018] During preparation, a hollow fiber tubular, sheet or thick tubular ceramic support is prepared by phase inversion spinning, the support has a porous structure with an average pore diameter of 1-2 microns; then, the mixed carbonate is fired to In the molten state, the molten carbonate is impregnated into the pores of the ceramic support by direct infiltration, filling the pores of the support...

Embodiment 2

[0020] A ceramic-carbonate dense dual-phase inorganic film with ceramic material as a support body, the inorganic film contains two phases, one phase is a ceramic phase as a support body, and the other phase is a carbonate phase; the material of the ceramic phase Samarium oxide doped with cerium oxide (Sm 2 o 3 doped-CeO 2 , SDC), the carbonate phase is a mixed carbonate; the carbonate phase is a mixed carbonate composed of lithium carbonate and sodium carbonate, and the mixing ratio of lithium carbonate and sodium carbonate is 52:48 mol%.

[0021] During preparation, a hollow fiber tubular and sheet-shaped ceramic support body is prepared by phase inversion spinning method, the support body is a porous structure with an average pore diameter of 1-2 microns; then, the mixed carbonate is fired to a molten state, The molten carbonate is impregnated into the pores of the ceramic support by direct infiltration to fill the pores of the support to form a dense ceramic-carbonate du...

Embodiment 3

[0023] A ceramic-carbonate dense dual-phase inorganic film with ceramic material as a support body, the inorganic film contains two phases, one phase is a ceramic phase as a support body, and the other phase is a carbonate phase; the material of the ceramic phase Samarium oxide doped with cerium oxide (Sm 2 o 3 doped-CeO 2 , SDC), the carbonate phase is a mixed carbonate; the carbonate phase is a mixed carbonate composed of lithium carbonate and sodium carbonate, and the mixing ratio of lithium carbonate and sodium carbonate is 52:48 mol%.

[0024] During preparation, a thick tubular ceramic support body is prepared by phase inversion spinning method. The support body has a porous structure with an average pore diameter of 1-2 microns; then, the mixed carbonate is fired to a molten state, and the Method The molten carbonate is impregnated into the pores of the ceramic support body to fill the pores of the support body to form a dense ceramic-carbonate dual-phase hollow fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com