High-frost-resistance concrete and preparation method thereof

A concrete and high frost resistance technology, applied in the field of high frost resistance concrete and its preparation, can solve the problems of increased concrete slump loss, concrete construction performance decline, etc., to improve the frost resistance performance, reduce the water-cement ratio, The effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

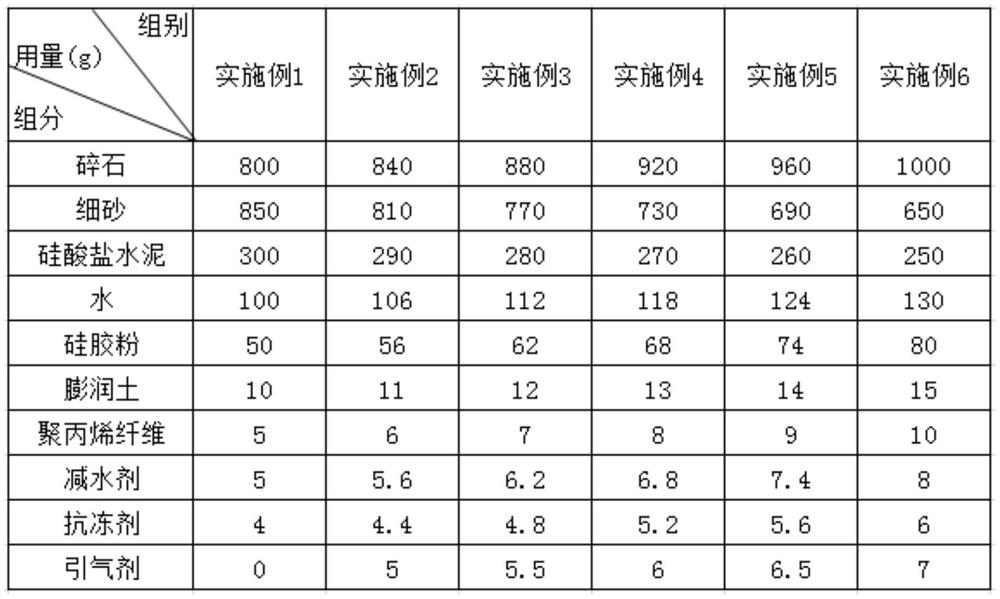

[0036] A high frost resistance concrete, its raw material components and dosage are shown in Table 1.

[0037] Table 1 embodiment 1-6 raw material component consumption table

[0038]

[0039] Among them, the antifreeze agent is calcium chloride.

[0040] The particle size of silica gel powder is 150-250μm, and the specific surface area is 300-400m 2 / g, the pore size is 80-100A°.

[0041] The water reducer is sodium lignosulfonate.

[0042] This embodiment also provides a method for preparing frost-resistant concrete, which includes the following steps: S1. Main ingredient mixing: mix fine sand and Portland cement and stir evenly, add gravel and mix evenly to obtain the premixed main ingredient ; S2. Mixing of auxiliary materials: silica gel powder and bentonite are mixed and stirred evenly, adding polypropylene fiber and 40% water, and stirred evenly to obtain slurry auxiliary materials;

[0043] S3. Additive mixing: Add the slurry auxiliary material obtained in the S...

Embodiment 2

[0045] A high frost resistance concrete, its raw material components and dosage are shown in Table 1.

[0046] Among them, the antifreeze agent is calcium chloride.

[0047] The particle size of silica gel powder is 150-250μm, and the specific surface area is 300-400m 2 / g, the pore size is 80-100A°.

[0048] The water reducer is sodium lignosulfonate.

[0049] This embodiment also provides a method for preparing frost-resistant concrete, which includes the following steps: S1. Main ingredient mixing: mix fine sand and Portland cement and stir evenly, add gravel and mix evenly to obtain the premixed main ingredient ; S2. Mixing of auxiliary materials: silica gel powder and bentonite are mixed and stirred evenly, adding polypropylene fiber and 40% water, and stirred evenly to obtain slurry auxiliary materials;

[0050] S3. Additive mixing: Add the slurry auxiliary material obtained in the S2 step to the premixed main material obtained in the S1 step, stir while adding the slur...

Embodiment 3

[0052] A kind of concrete with high frost resistance, the difference between this embodiment and embodiment 2 is that its raw material components and dosage are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com