Environment-friendly plant fiber foaming and sound absorption material and preparation method thereof as well as water filtering mold and molding device

A technology of plant fibers and sound-absorbing materials, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as insolubility, environmental pollution, and inability to melt, achieve convenient operation, reduce free water content, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

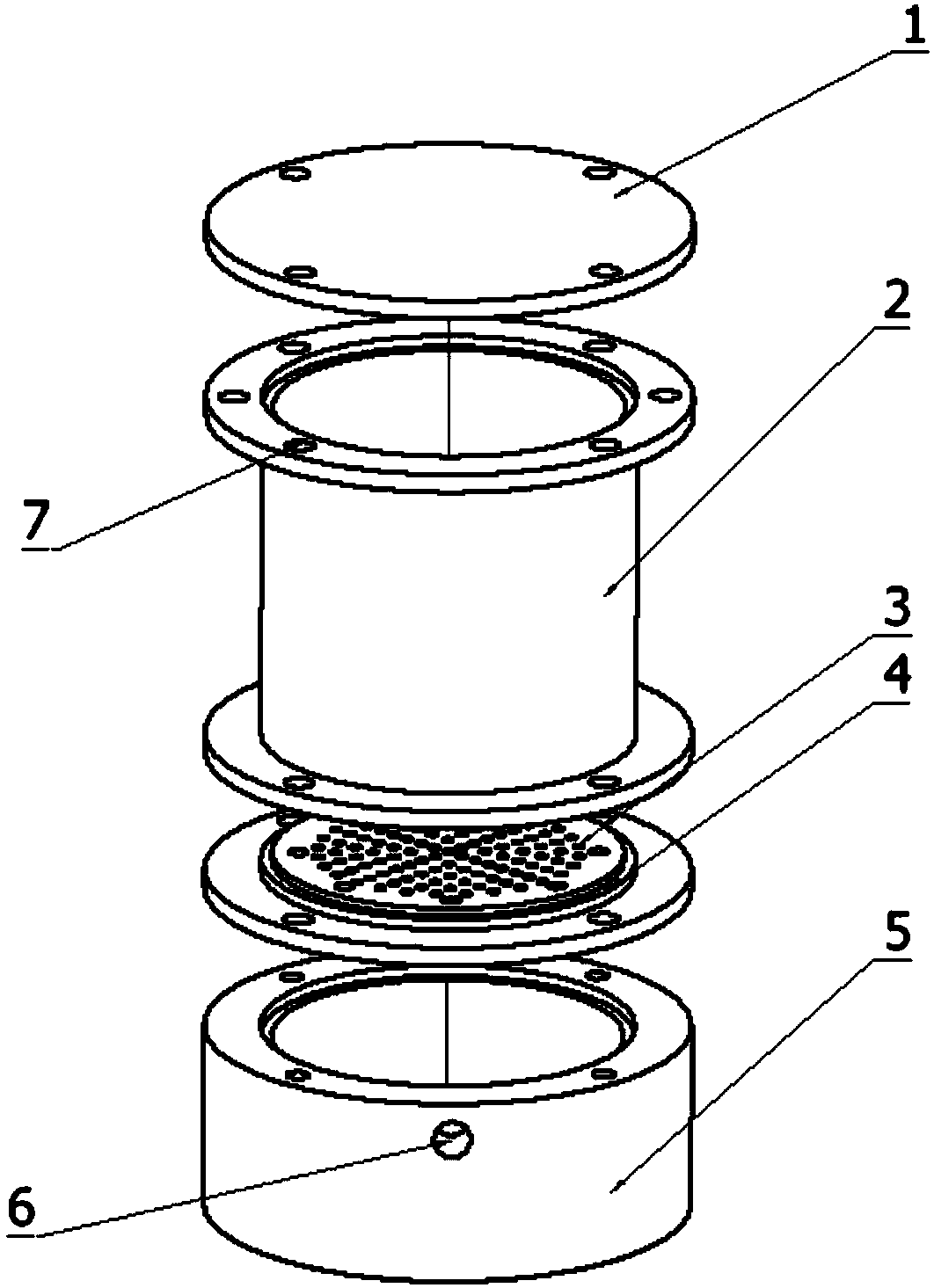

Image

Examples

Embodiment 1

[0055] (1) Take 16g of corrugated cardboard and bagasse pulp board with core paper removed and tear them into small pieces, soak them in water for 5 hours, then dissociate them in a decomposer for 5000 rpm, filter the water and put them in a sealed bag to balance the water for 24 hours.

[0056] (2) Mix waste paper pulp obtained in step (1) with bagasse pulp at a mass ratio of 1:1, and mix 0.64 g of sodium hydroxide solid with the mixed slurry so that the mass fraction of the mixed slurry is 10%, Treat it in a water bath at 70°C for 30 minutes, and rub it every 10 minutes.

[0057] (3) Take 2.4g of polyvinyl alcohol in 50ML of deionized water and stir in an oil bath at 90°C for 40min.

[0058] (4) Take 8g of cornstarch and stir in a 70°C water bath until gelatinized.

[0059] (5) Wash away the sodium hydroxide in the solution in step (2), then mix the gelatinized cornstarch with the dissolved PVA solution cooled to room temperature, then add 3g of calcium carbonate, 0.4g of b...

Embodiment 2

[0065] (1) Take 16g of corrugated cardboard and bagasse pulp board with core paper removed and tear them into small pieces, soak them in water for 5 hours, then dissociate them in a decomposer for 5000 rpm, filter the water and put them in a sealed bag to balance the water for 24 hours.

[0066] (2) Mix waste paper pulp obtained in step (1) with bagasse pulp at a mass ratio of 1:1, and mix 0.64 g of sodium hydroxide solid with the mixed slurry so that the mass fraction of the mixed slurry is 10%, Treat it in a water bath at 70°C for 30 minutes, and rub it every 10 minutes.

[0067] (3) Take 4g of polyvinyl alcohol in 50ML of deionized water and stir in an oil bath at 90°C for 40min.

[0068] (4) Take 8g of cornstarch and stir in a 70°C water bath until gelatinized.

[0069] (5) Wash off the sodium hydroxide in the solution in step 2), then mix the gelatinized cornstarch with the PVA solution that has been dissolved and cooled to room temperature, and then add 3g of calcium ca...

Embodiment 3

[0075] (1) Take 16g of corrugated cardboard and bagasse pulp board with core paper removed and tear them into small pieces, soak them in water for 5 hours, then dissociate them in a decomposer for 5000 rpm, filter the water and put them in a sealed bag to balance the water for 24 hours.

[0076] (2) Mix waste paper pulp obtained in step (1) with bagasse pulp at a mass ratio of 1:1, and mix 0.64 g of sodium hydroxide solid with the mixed slurry so that the mass fraction of the mixed slurry is 10%, Treat it in a water bath at 70°C for 30 minutes, and rub it every 10 minutes.

[0077] (3) Take 4g of polyvinyl alcohol in 50ML of deionized water and stir in an oil bath at 90°C for 40min.

[0078] (4) Take 8g of cornstarch and stir in a 70°C water bath until gelatinized.

[0079] (5) Wash away the sodium hydroxide in the solution in step 2), then mix the gelatinized cornstarch with the PVA solution that has been dissolved and cooled to room temperature, then add 3g of calcium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com