Operation method of dual-power pulverizer

An operation method and pulverizer technology, the operation method applied to the dual-power pulverizer belongs to the processing field, and can solve the problems of no softness and hard texture of mugwort leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

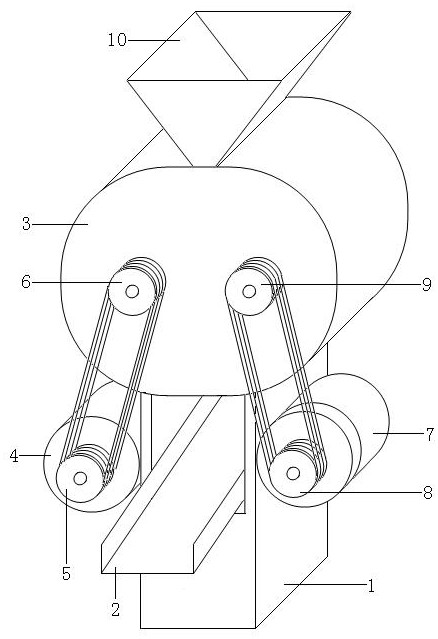

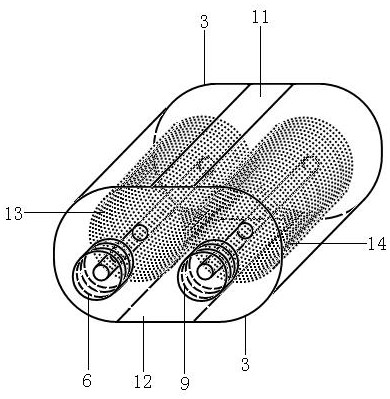

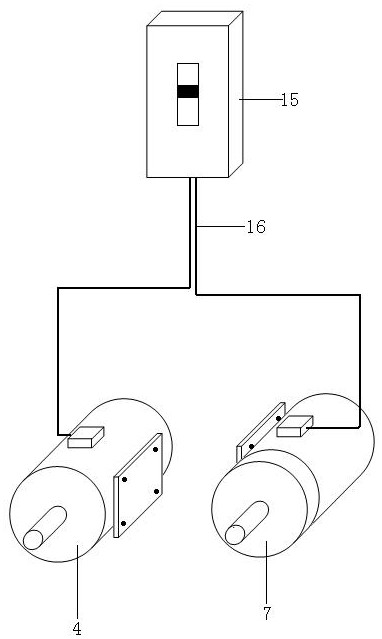

[0015] Now describe in detail the shape and structure of the present invention in conjunction with accompanying drawings and reference numerals:

[0016] A dual-power pulverizer includes a base 1, a discharge chute 2, a casing 3, a high-speed motor (AC380V / 5-7kw, 2800r / min) 4, a high-speed motor pulley 5, a high-speed crushing drum pulley 6, and a low-speed motor (AC380V / 5-7kw, 960r / min) 7, low-speed motor pulley 8, low-speed crushing drum pulley 9, hopper 10, feed inlet 11, discharge port 12, high-speed crushing drum 13, low-speed crushing drum 14, power switch (AC400V / 80A ) 15, power cord (4x4mm²) 16;

[0017] The base is hollow and rectangular, and a rectangular discharge chute is arranged in the middle of the upper interior inclined forward at 45°, a casing is arranged horizontally above the top, and a cylindrical high-speed motor and a high-speed motor are arranged horizontally and longitudinally on the left side. A cylindrical high-speed motor pulley is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com