Hydrogel and uses therefor

A hydrogel, unsaturated technology, applied in the direction of electrolyte immobilization/gelation, aqueous electrolyte, structural parts, etc., can solve the problems of reducing electrolyte, low alkali resistance of lithium ion conductive solid electrolyte, etc. Effects of increase in interface resistance, excellent mechanical strength, and excellent ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

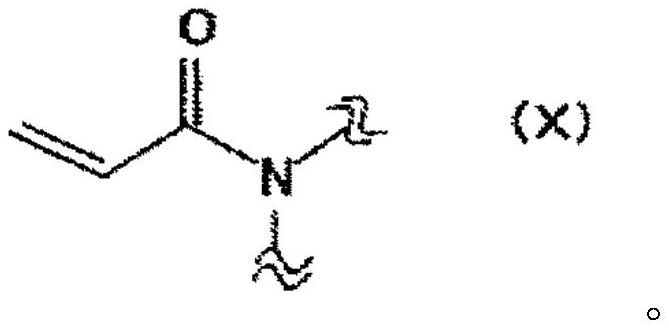

Image

Examples

Embodiment 1a

[0234] 20 parts by mass of acrylic acid (manufactured by Toagosei Co., Ltd.) as a monofunctional monomer and N,N',N"-triacryloyldiethylenetriamine (Fuji Film Co., Ltd., FAM301, melting point 89 ° C) 0.34 parts by mass, 80 parts by mass of ion-exchanged water and stirred. Add 0.20 parts by mass of Omnirad1173 (manufactured by BASF Japan Ltd.) as a polymerization initiator to the solution, and use a magnetic stirrer (RS-6AR manufactured by As One Co., Ltd.) was stirred to prepare a hydrogel precursor. A 2mm thick silicon frame was placed on the peelable PET film, and after injecting the hydrogel precursor in the frame, before the hydrogel A peelable PET film is placed on the body. After that, in a small-sized UV polymerizer (manufactured by JATEC Corporation, J-cure1500, metal halide lamp model name MJ-1500L), carry out the process at a conveyor speed of 0.4m / min and a distance of 150mm between workpieces. Under the conditions of irradiation energy 7000mJ / cm 2 The UV-ray proces...

Embodiment 2a

[0237] Change the multifunctional monomer to N,N'-{[(2-acrylamide-2-[(3-acrylamide propoxy)methyl]propane-1,3-diyl)bis(oxyl) A hydrogel was obtained in the same manner as in Example 1a except that 0.66 parts by mass of bis(propane-1,3-diyl)}bisacrylamide (manufactured by Fujifilm Corporation, FAM401, melting point 107° C.) was used. Evaluation of the swelling properties of the obtained hydrogel, a puncture test after immersion in an alkaline solution, a DC polarization test, a charge-discharge test, and an appearance evaluation after immersion in an electrolyte solution were performed.

Embodiment 3a

[0239] In addition to changing the polyfunctional monomer to 0.47 parts by mass of N,N',N",N"'-tetraacryloyltriethylenetetramine (manufactured by Fujifilm Co., Ltd., FAM402, melting point 110°C), and A hydrogel was obtained in the same manner as in Example 1a. Evaluation of the swelling properties of the obtained hydrogel, a puncture test after immersion in an alkaline solution, a DC polarization test, a charge-discharge test, and an appearance evaluation after immersion in an electrolyte solution were performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com