Organic single-crystal semiconductor structure and preparation method thereof

A single crystal semiconductor, organic semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical solid-state devices, etc., to achieve efficient extraction and injection, and overcome the effects of transmission traps/defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

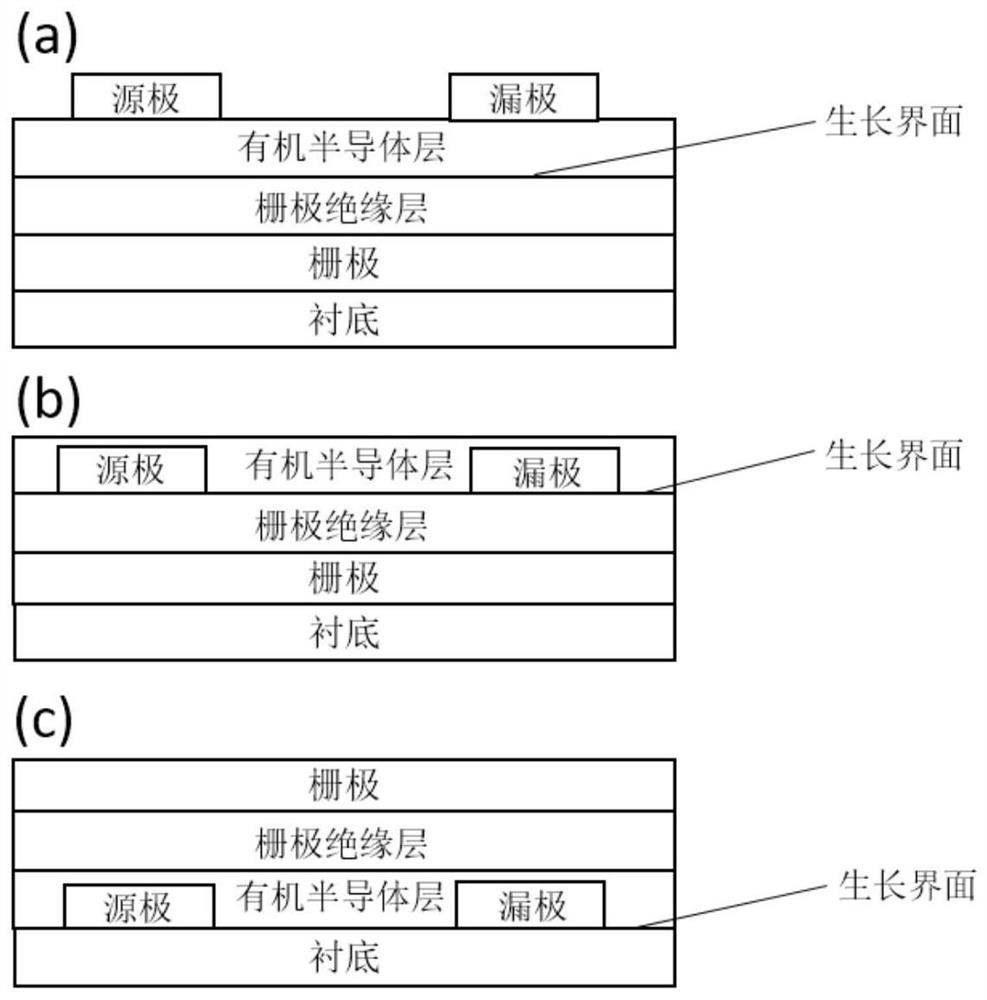

[0126] Example 1: A bottom-contact organic single crystal semiconductor structure based on 6,13-bis(triisopropylsilylethynyl)pentacene (TIPS-pentacene) and a top-gate bottom-contact structure based on this The preparation method of the field effect transistor device, comprises the following steps:

[0127] (1) Take a P-type silicon wafer with a thickness of 575 μm. There is a 300 nm thick silicon dioxide insulating layer on the silicon wafer, and spin-coat cross-linked polystyrene on the silicon substrate to prepare an auxiliary growth layer;

[0128] (2) On the initial film prepared in step (1), a long strip of Au with a thickness of about 30 nm is deposited by thermal evaporation under high vacuum as the source and drain electrodes, and the upper surface of the auxiliary growth layer is in contact with the lower surface of the electrode , the contact mode is the upper type;

[0129] (3) Regulate the temperature of the growth environment to be 20±1°C, and the humidity to be...

Embodiment 2

[0136] Example 2: A bottom-contact organic single crystal semiconductor structure based on 6,13-bis(triisopropylsilylethynyl)pentacene (TIPS-pentacene) and a top-gate bottom-contact structure based on this Fabrication methods of field effect transistor devices.

[0137] Refer to Example 1 for the preparation method of the field effect transistor device in Example 2, and the formula and process parameters are shown in Table 1 and Table 2. The structure and performance characterization methods are the same as those in Example 1. The obtained device properties are shown in Table 4.

Embodiment 3

[0138] Example 3: A bottom-contact organic single crystal semiconductor structure based on 6,13-bis(triisopropylsilylethynyl)pentacene (TIPS-pentacene) and a top-gate bottom-contact structure based on this Fabrication methods of field effect transistor devices.

[0139] Refer to Example 1 for the preparation method of the field effect transistor device of Example 3, and the formula and process parameters are shown in Table 1 and Table 2. The structure and performance characterization methods are the same as those in Example 1. The obtained device properties are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com