Multifunctional air cylinder reliable disconnection type nitrogen rapid purging device

A multi-functional, disconnected technology, applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problem of lack of safety interlock control supporting devices, etc., and achieve the effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

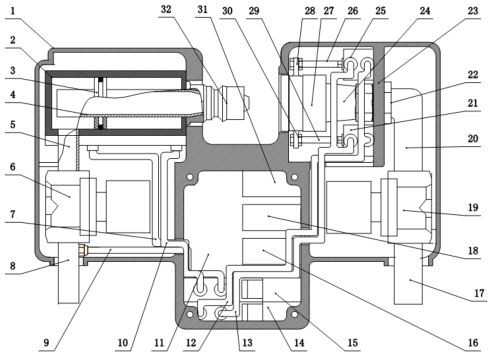

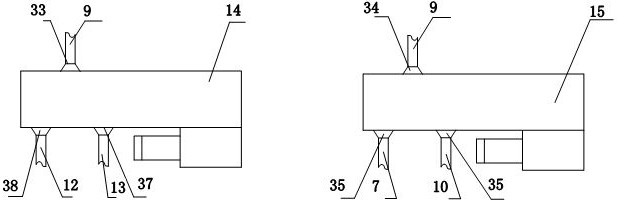

[0020] Embodiment of the invention, it comprises: housing 1, and the middle and lower part of housing 1 is provided with intermediate room 11, and the upper part of intermediate room 11 is provided with time relay one 16, time relay two 18, time relay three 31, and the lower part is provided with two Five-position solenoid valve one 14, two-position five-way solenoid valve two 15;

[0021] The left side of the housing 1 is equipped with a multifunctional main cylinder 2, and the multifunctional main cylinder 2 is provided with a cylinder tube 4. The left side of the cylinder tube 4 is equipped with a cylinder plug 3, and the right end is equipped with a quick connector male head 32;

[0022] There is a nitrogen connecting pipe 5 under the left end of the multifunctional main cylinder 2, and the lower end of the nitrogen connecting pipe 5 is connected with an explosion-proof nitrogen valve 6, and the lower end of the explosion-proof nitrogen valve 6 is connected with a nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com