Lubricating oil system of gas turbine

A technology of gas turbine and lubricating oil, which is applied in the direction of gas turbine device, engine lubrication, turbine/propulsion device lubrication, etc., and can solve problems such as increasing oil consumption, hindering system oil return, and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

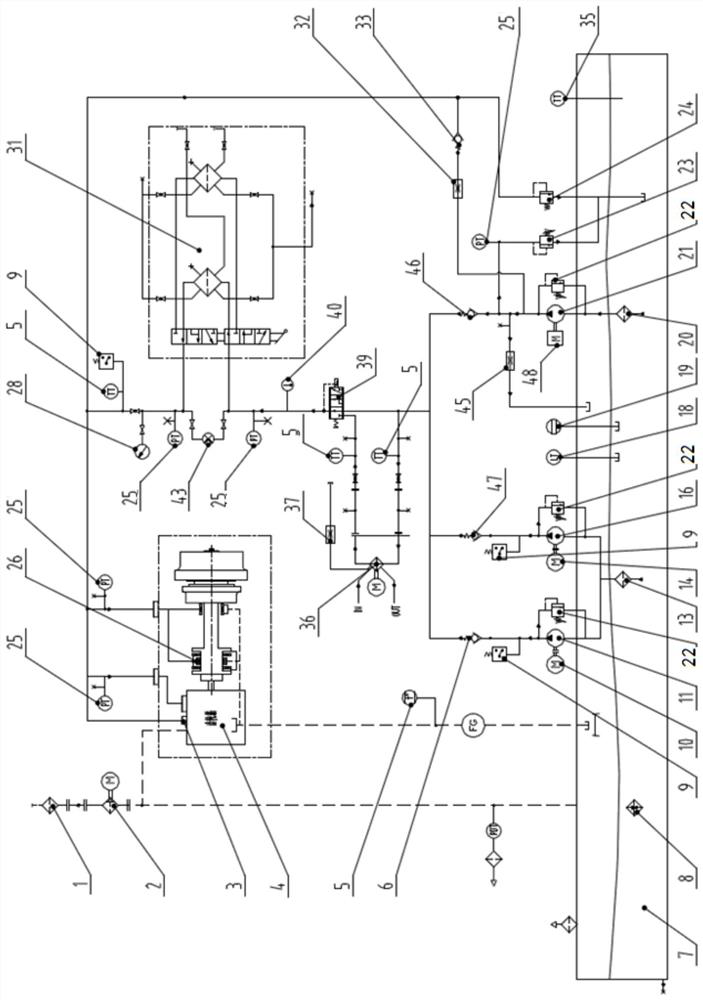

[0091] Such as figure 1 As shown, the gas turbine lubricating oil system includes a main pump 21, an auxiliary pump 16, an oil combination valve block, an oil separation valve block, and a main pump pre-lubrication pipeline;

[0092] The main pump 21 pumps out lubricating oil from the lubricating oil tank 7 during its work and sends it to the main oil supply pipeline through the main pump pipeline through the oil valve block;

[0093] The auxiliary pump 16 pumps out lubricating oil from the lubricating oil tank 7 during its work and sends it to the main oil supply pipeline through the auxiliary pump pipeline through the oil valve block;

[0094] The main pump pipeline is provided with a main pump check valve 46, and the liquid inlet of the main pump check valve 46 is on the side of the main pump 21;

[0095] The auxiliary pump pipeline is provided with an auxiliary pump check valve 47, and the liquid inlet of the auxiliary pump check valve 47 is on the side of the auxiliary p...

Embodiment 2

[0105] Based on Embodiment 1, the gas turbine lubricating oil system also includes a backup pump 11;

[0106] The standby pump 11 pumps lubricating oil from the lubricating oil tank 7 and sends it to the main oil supply pipeline through the standby pump pipeline through the oil valve block when it works;

[0107] A backup pump check valve 6 is arranged on the backup pump pipeline, and the liquid inlet of the backup pump check valve 6 is on the side of the backup pump 11 .

[0108] In the gas turbine lubricating oil system of Embodiment 2, three pumps, the main pump 21 , the auxiliary pump 16 and the standby pump 11 , provide lubricating oil for the main oil supply pipeline. The check valve makes the oil passages of the main pump 21, auxiliary pump 16 and backup pump 11 independent without interfering with each other. During the operation of the gas turbine, through the mutual cooperation of the three pumps, the gas turbine bearing chamber 26, the gearbox 4 and the output shaft...

Embodiment 3

[0110] Based on the second embodiment, the gas turbine lubricating oil system also includes a control circuit;

[0111] The auxiliary pump 16 is driven by an AC motor 14, and the AC motor is powered by a diesel generator before the gas turbine is started, and is switched to a gas turbine for power supply after the gas turbine is started;

[0112] The standby pump 11 is driven by a DC motor 10, and the DC motor is powered by a battery pack;

[0113] The control circuit:

[0114] When the gas turbine stops for more than the set time (for example, 30 minutes), before the gas turbine is started, the standby pump 11 is controlled not to work, and the diesel generator is controlled to start to supply power to the AC motor 14 to drive the auxiliary pump 16 to work. Pump oil from the lubricating oil tank 7, and the main pump 21 The gas turbine cannot be driven by the auxiliary gear 48 of the gearbox to work because the gas turbine is not started;

[0115] During the start-up process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com